Three-dimensional weaving guide rod online insertion detection method based on machine vision

A three-dimensional weaving and machine vision technology, applied in textiles and papermaking, neural learning methods, auxiliary equipment for weaving, etc., can solve the problems of easy missed inspection, high cost, large number of holes, etc. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

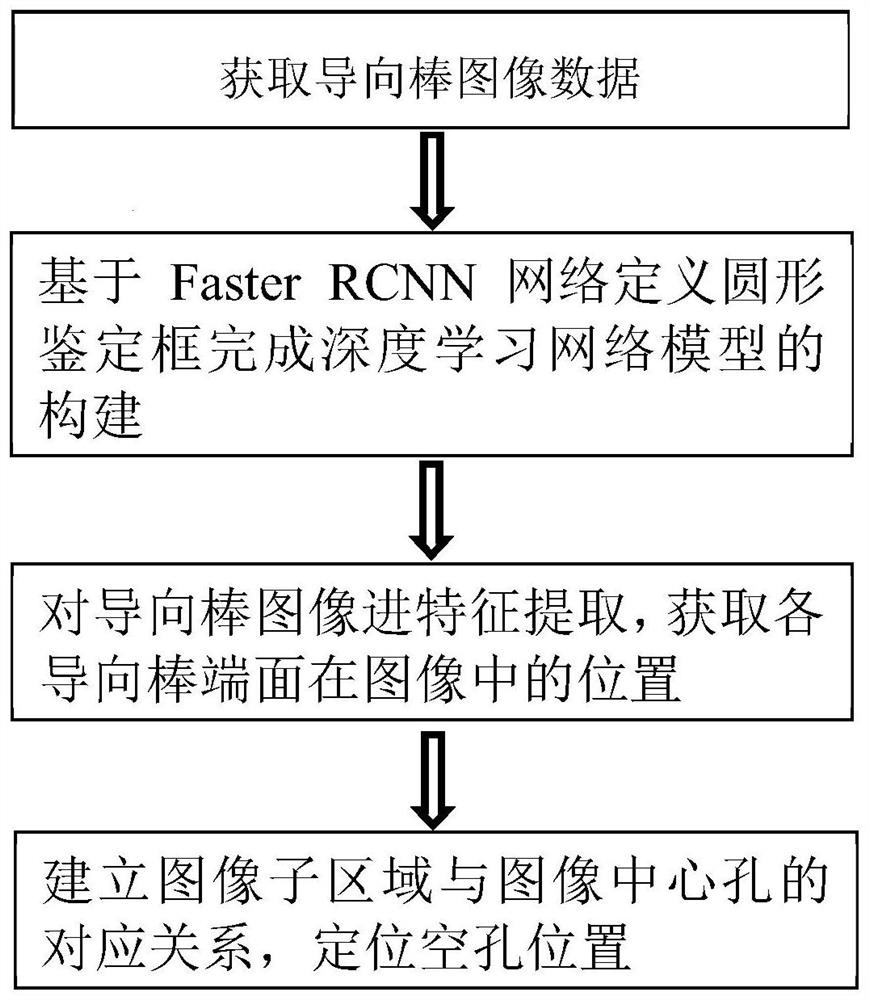

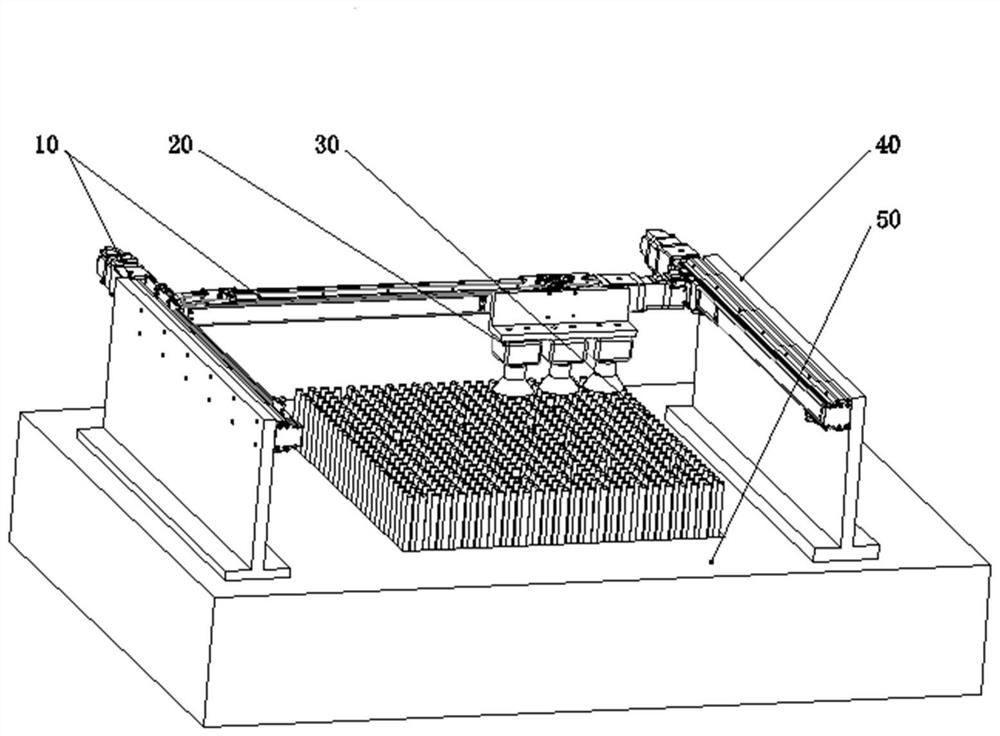

[0025] Aiming at the problems of low efficiency and high cost caused by the traditional guide rod placement detection largely relying on manual work, the present invention provides a machine vision-based online placement detection method for three-dimensional weaving guide rods, such as figure 1 , including the following steps:

[0026] (1) The detection device is equipped with a line-scanning camera to collect images above the guide template to form an image set, manually mark the guide rods inserted into the guide holes in the image set, and divide the image set into a training set and a test set;

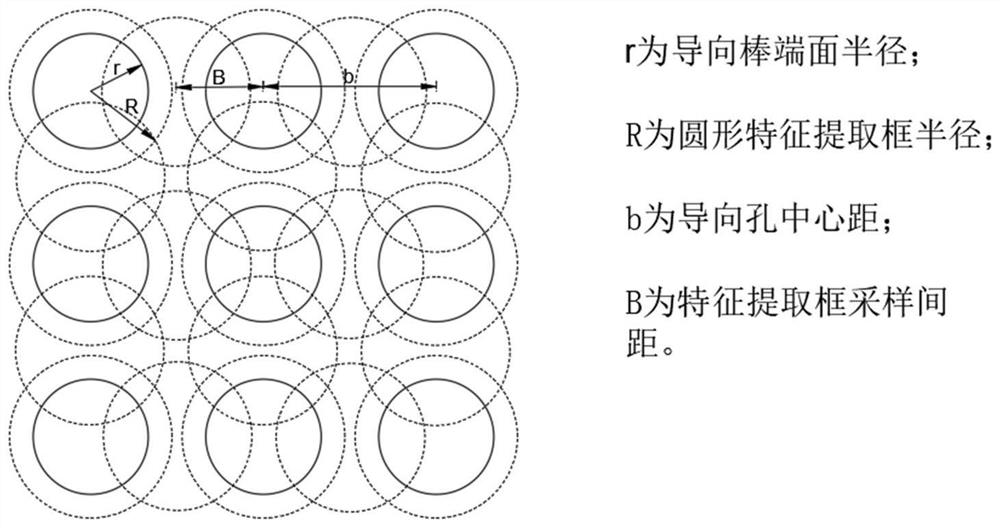

[0027] (2) Set the region proposal generation network feature extraction box in the Faster RCNN model to a circle, input the artificially marked training set into the Faster RCNN model for training until the loss function converges, use the test ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com