Permanent magnet generator for offshore wind power and working method thereof

A permanent magnet generator and offshore wind power technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of reducing wind power generation efficiency, difficulty in maintenance and repair, and adding electric equipment, so as to avoid downtime accidents and maintenance needs , avoid ionization and electric corrosion, reduce the effect of weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

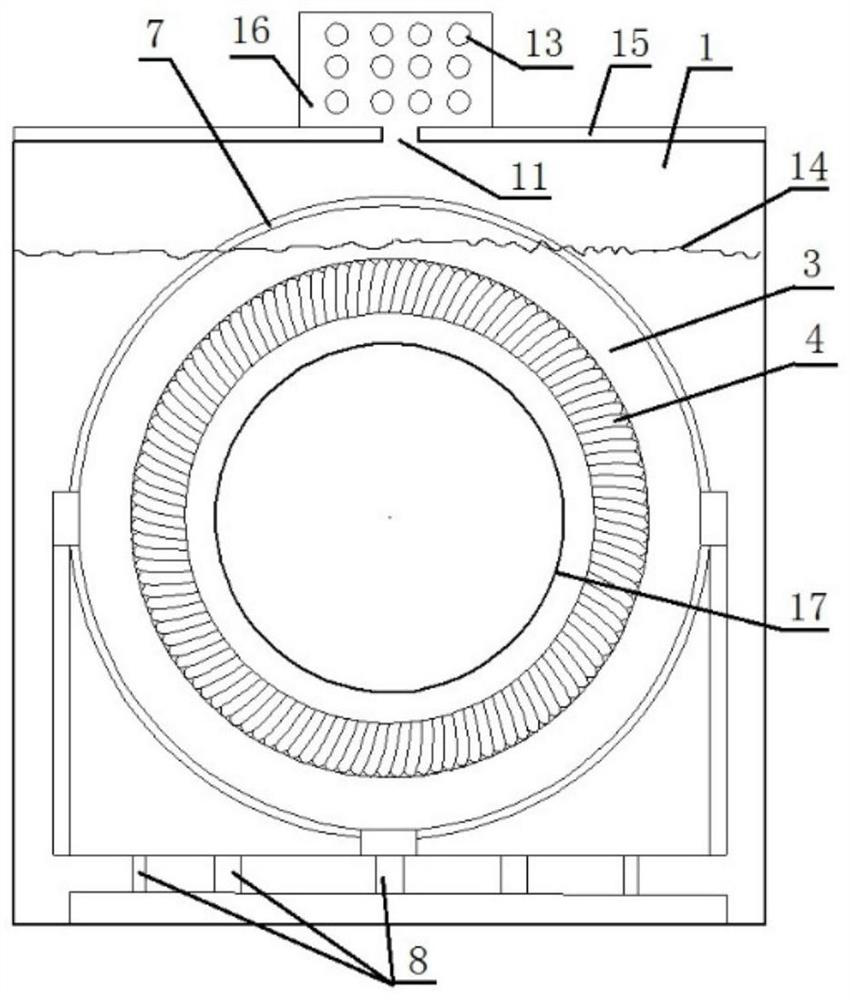

[0036] Such as figure 1 As shown, this embodiment provides a permanent magnet generator for offshore wind power, including at least a stator and a rotor 2, and a cooling cavity;

[0037] The rotor 2 is located outside the cooling cavity, and the stator is located inside the cooling cavity; the inside of the cooling cavity is filled with a cooling medium 18;

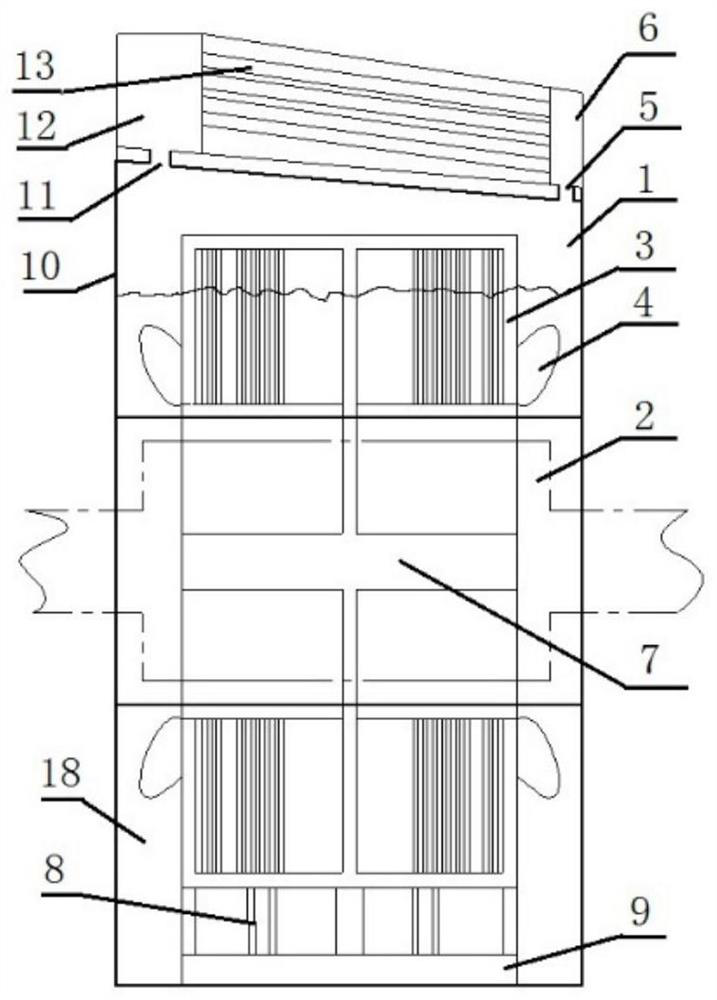

[0038] In this embodiment, the cooling cavity can be set as a glass fiber reinforced plastic cavity; figure 1 with figure 2 As shown, the FRP cavity 1 is composed of a cavity FRP 10 and an inner cavity FRP 17 to form a closed cooling cavity except the outlet 11 and the inlet 5 .

[0039] In this example, if figure 1 As shown, the stator includes a stator core 3, and one end of the stator core 3 is connected to a generator frame 9; the generator frame 9 is located inside the cooling cavity and is soaked in the cooling medium 18 Inside; the elastic connection between the stator core 3 and the generator base 9 can be re...

Embodiment 2

[0050] This embodiment further illustrates the permanent magnet generator for offshore wind power in Embodiment 1; specifically:

[0051] The stator core 3 and the stator coil form a whole, which are embedded in a steel cage 7 welded by steel pipes to form the stator of the generator. The stator has no stator casing, which not only reduces the weight of the stator, but also facilitates the heat dissipation of the stator core and the coil; the whole The stator core, stator coil and stator cage 7 are welded to the generator frame through the elastic support made of steel pipes, which can effectively reduce the high-frequency vibration generated during the operation of the generator and transmit it to the frame, so as to avoid damage to the glass fiber reinforced plastic cavity under the frame. Underseat damage.

[0052] The whole stator core 3, stator coil, stator cage 7 and generator base 9 form a whole and are placed in an airtight structure made of glass fiber reinforced plas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com