Method for prolonging fracturing validity period of intersalt argillaceous dolomite reservoir and application thereof

A long-term, fracturing technology, applied in earth-moving drilling, wellbore/well components, and production fluids, etc., can solve problems such as large gaps and small contact areas, and achieve increased stimulation volume, improved conductivity, and reduced salt rock. Effects of dissolution or creep

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

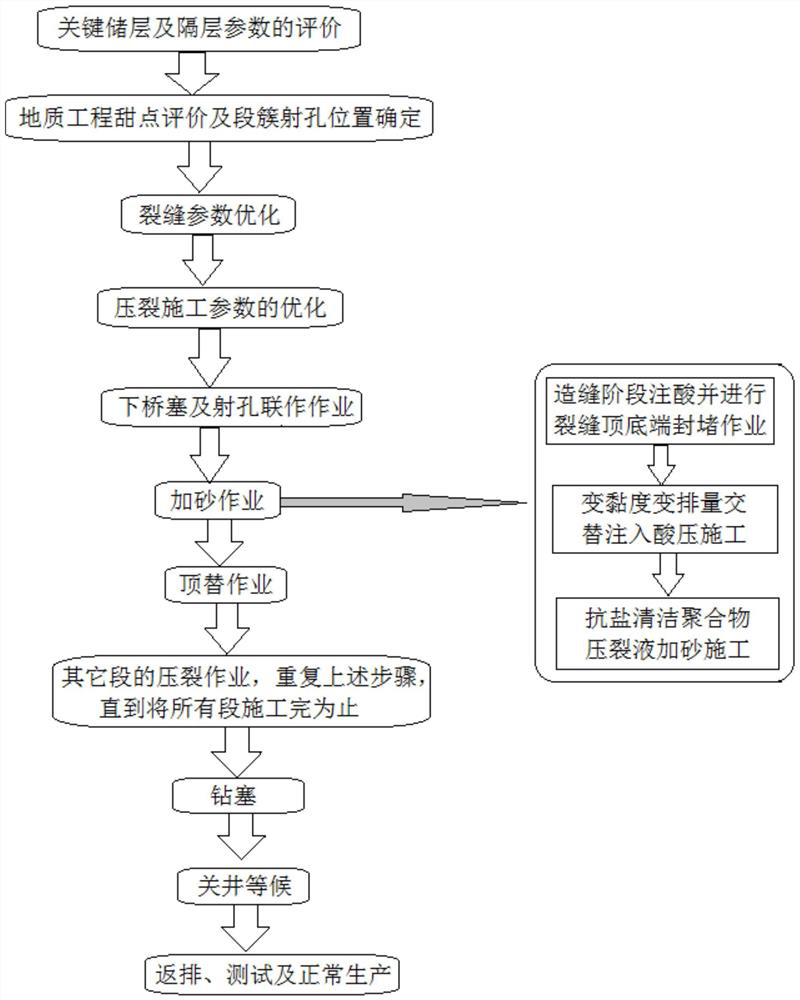

Method used

Image

Examples

Embodiment 1

[0082] Well X is an evaluation horizontal well in Jianghan Oilfield. The completion method is casing completion. The structural location is the south slope of the Benghu syncline in the Qianjiang Sag. The drilling completion layer is the potential 3 4 -10 rhythm, the vertical depth of target point A of the horizontal well is 3153m, the vertical depth of target point B is 3333m, and the horizontal section is 500m long. 4 -10 rhyme capacity. The reservoir lithology of this well is mainly carbon-rich laminated argillaceous dolomite, with 25.97% calcite, 24.46% dolomite, 13.41% quartz + feldspar, 25.14% clay, and 4.03% salt. The upper and lower barriers are salt rock layers, the thickness of the reservoir is 10m, the thickness of the upper barrier is 20m, and the thickness of the lower barrier is 10m. The stress difference between the reservoir and the barrier is relatively large, which can play a good barrier effect. The reservoir pressure coefficient is 1.06-1.16, and the reser...

Embodiment 2

[0108] Well Y is a development horizontal well in Jianghan Oilfield, the completion method is casing completion, the structural location is the south slope of the Benghu syncline in the Qianjiang Sag, and the drilling completion layer is the potential 3 4 -10 rhythm, horizontal well A target point vertical depth is 3019.6m, B target point vertical depth is 3176.3m, and the horizontal section is 800m long. 4 -10 Experimental application of rhythmic new technology and new technology. The reservoir lithology of this well is mainly carbon-rich laminated argillaceous dolomite, with 23.44% calcite, 29.52% dolomite, 19.78% quartz + feldspar, 21.3% clay, and 6.03% salt. The upper and lower barriers are salt rock layers, the thickness of the reservoir is 7.6m, the thickness of the upper barrier is 17m, and the thickness of the lower barrier is 12m. The stress difference between the reservoir and the barrier is relatively large, which can play a good barrier role. The reservoir pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com