Oil temperature control mechanism, refrigerating system, air conditioner and oil temperature control method

A technology of oil temperature control and refrigeration system, applied in the field of oil temperature control and oil temperature control mechanism, can solve the problems of high lubricating oil temperature and insufficient cooling of lubricating oil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The embodiment describes the oil temperature control mechanism of the invention in detail.

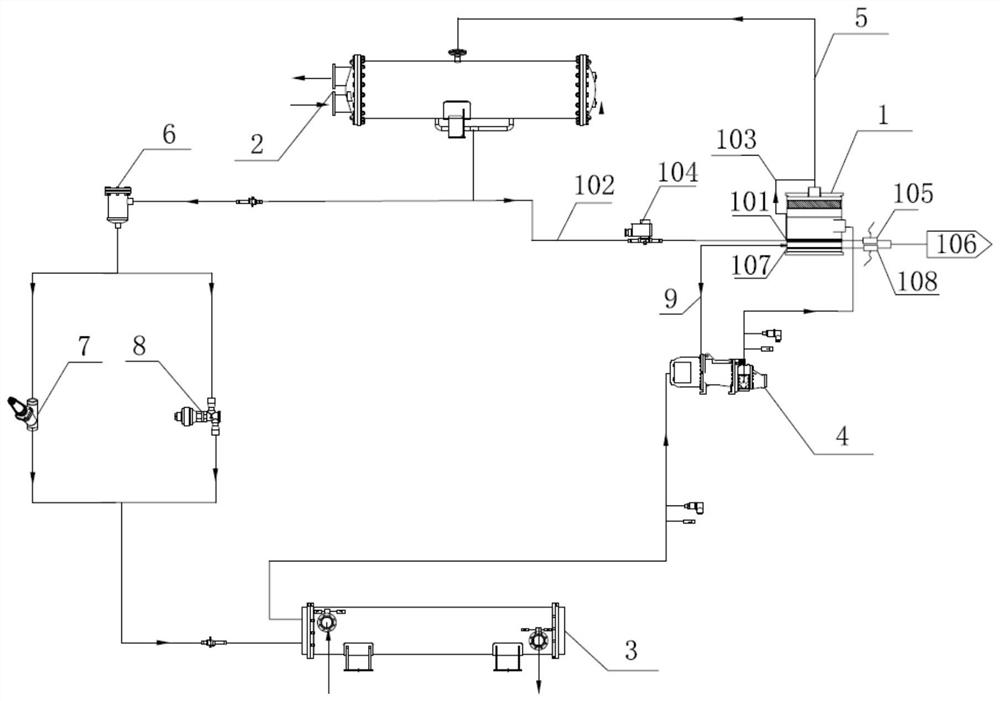

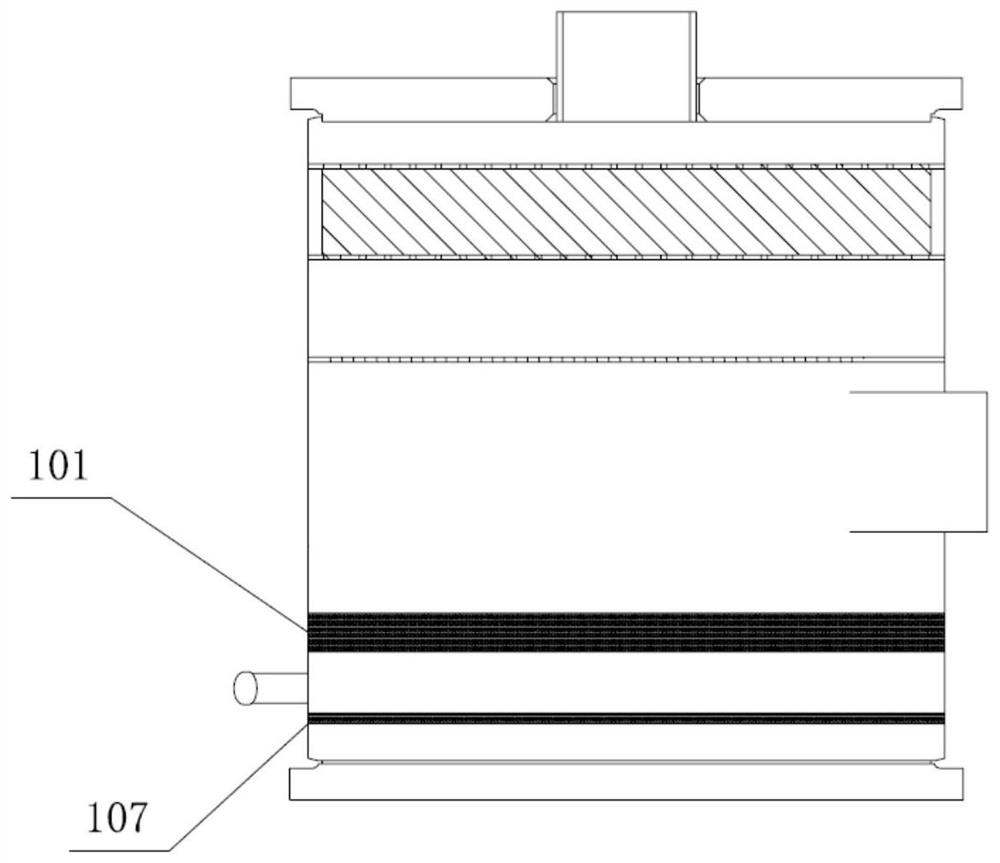

[0041] The oil temperature control mechanism of this embodiment includes a cooling pipeline 101, a cooling pipeline 102 and an air return pipeline 103, such as Figure 1 and Figure 2 As shown in. Preferably, the cooling pipeline 101 is arranged on the outer wall of the oil separator 1, the two ends of the cooling pipeline 102 are respectively connected with the refrigerant outlet end of the condenser 2 and the inlet end of the cooling pipeline 101, and the two ends of the air return pipeline 103 are respectively connected with the outlet end of the cooling pipeline 101 and the refrigerant inlet end of the condenser 2; The refrigerant in the condenser 2 enters the cooling pipeline 101 through the cooling pipeline 102 to exchange heat with the oil separator 1, and the heat exchanged refrigerant enters the refrigerant inlet end of the condenser 2 through the air return pipeline 103, as ...

Embodiment 2

[0050] The embodiment describes the oil temperature control method of the invention in detail.

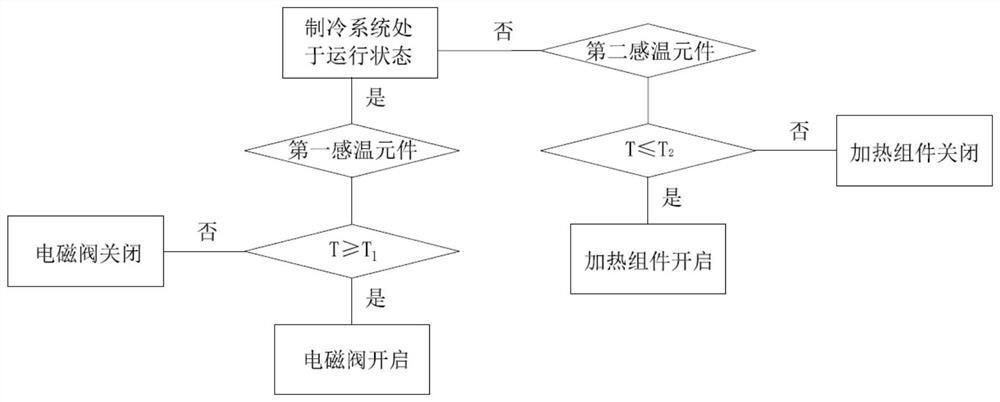

[0051] Figure 3A flow chart of a preferred embodiment of the oil temperature control method of the present embodiment is shown. as Figure 3 As shown in, the oil temperature control method using the oil temperature control mechanism of any one of embodiment 1 includes the following steps:

[0052] S1: judge the operation state of the refrigeration system.

[0053] S21: during the operation of refrigeration system, detect the lubricating oil temperature in oil separator 1. T≥T 1 Control the refrigerant flowing out of the refrigerant outlet end of condenser 2 to exchange heat with the lubricating oil in oil separator 1, and make the refrigerant after heat exchange enter the refrigerant inlet end of condenser 2; T<T 1 When, the refrigerant flowing out of the refrigerant outlet end of condenser 2 is controlled to enter evaporator 3, where t is the lubricating oil temperature in oil separat...

Embodiment 3

[0059] The embodiment describes the refrigeration system of the invention in detail.

[0060] The refrigeration system of this embodiment comprises an oil separator 1, a condenser 2, an evaporator 3, a compressor 4 and an oil temperature control mechanism, wherein the oil separator 1, the condenser 2, the evaporator 3, the compressor 4 and the oil separator 1 are successively connected and form a refrigerant circuit, such as Figure 1 As shown in. Preferably, the oil temperature control mechanism is the oil temperature control mechanism of any technical scheme in embodiment 1.

[0061] See again Figure 1 The inlet end of the refrigerant system 6 and the outlet end of the refrigerant system 9 of the embodiment are connected with the expansion valve of the refrigerant system 6 and the expansion valve of the refrigerant system 6, wherein the expansion valve of the refrigerant system 6 and the expansion valve of the embodiment are also connected with the inlet end of the refrigerant sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com