Construction method of acidic rice seedling raising soil rich in artificial humus

A technology of rice seedling raising and construction method, which is applied in the field of rice seedling raising soil construction, can solve the problems of high-quality soil and soil ecological environment deterioration, soil resource shortage, etc., achieve structure and function optimization, improve barren soil, and meet the needs of seedling raising Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

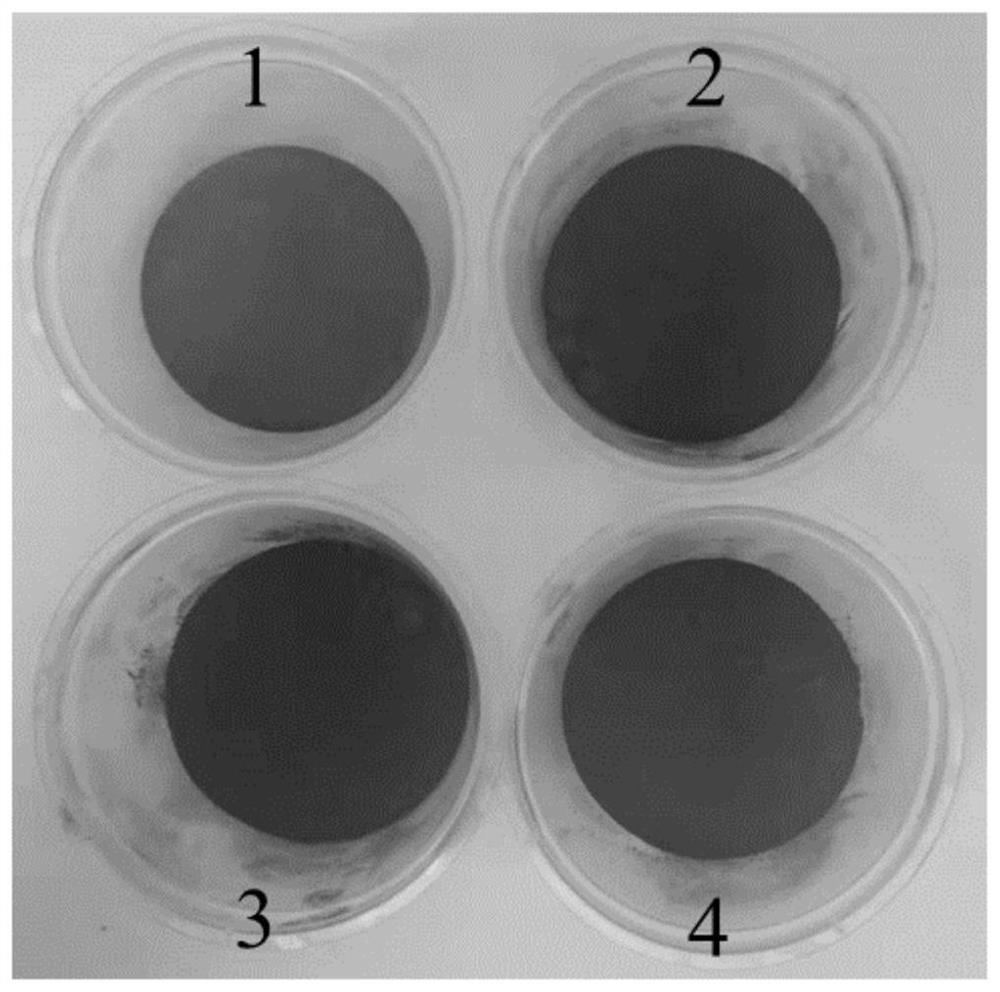

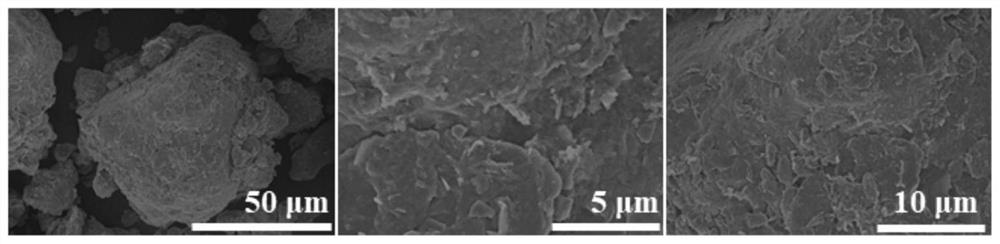

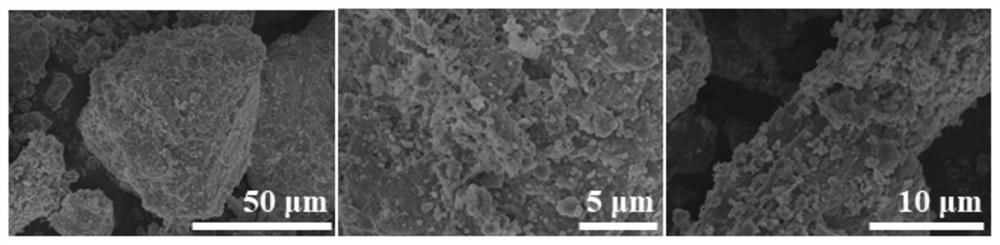

Image

Examples

specific Embodiment approach 1

[0026] Specific implementation mode one: a kind of construction method of the acid rice seedling-raising soil that is rich in artificial humus in this embodiment is specifically completed according to the following steps:

[0027] 1. Prepare the soil mixture:

[0028] Mix the biomass material powder with the barrier soil, then add active additives and distilled water, and stir evenly to obtain a soil mixture;

[0029] The mass ratio of biomass material powder, barrier soil, active additive and distilled water described in step 1 is (10~30):(8~100):(1~4):(150~400);

[0030] 2. Preparation of humified soil:

[0031] ①. Put the soil mixture in a high-temperature and high-pressure hydrothermal reaction kettle, then raise the temperature of the high-temperature and high-pressure hydrothermal reaction kettle to 180°C to 220°C, and water under the conditions of a temperature of 180°C to 220°C and a pressure of 0.8MPa to 2.5MPa. Thermal reaction for 20h-28h to obtain the reaction pr...

specific Embodiment approach 2

[0034] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the particle size of the biomass material powder described in step 1 is 50 mesh to 200 mesh, and it is specifically prepared according to the following steps: first, the biomass material powder Cleaning is performed to remove impurities on the surface of the biomass material, and then drying at 60° C. to 80° C. for 10 hours to 24 hours, and finally the dried biomass material is pulverized to obtain biomass material powder. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0035] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the biomass material is one or several of rice straw, corn straw, soybean straw, rice husk, leaves and sawdust. mixture of species. Other steps are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com