Whole oat milk preparation method and device

A preparation device and oatmeal technology, which is applied in the field of whole oat milk preparation, can solve the problems of low production efficiency and unfavorable rapid production of enterprises, and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

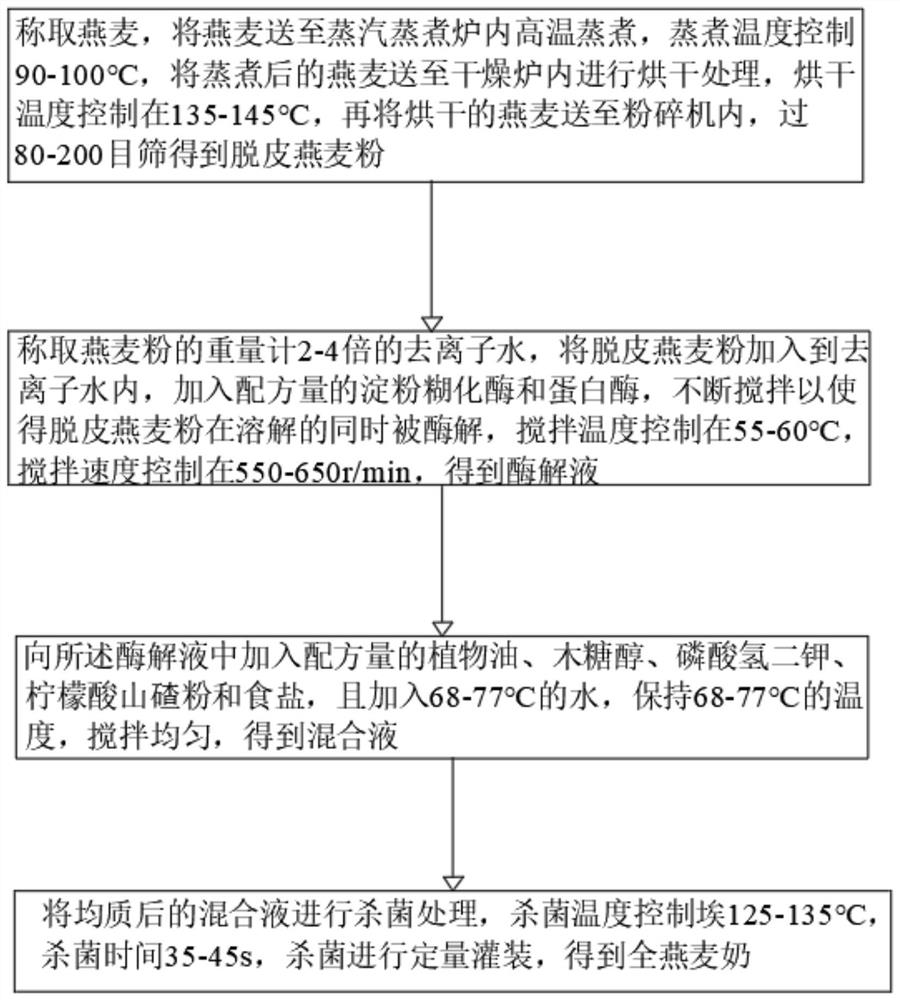

[0045] refer to figure 1 Described, a kind of whole oat milk preparation method comprises the following steps;

[0046] Step 1 Weigh the oats, send the oats to the steam cooking furnace for high temperature cooking, the cooking temperature is controlled at 100°C, send the cooked oats to the drying furnace for drying treatment, the drying temperature is controlled at 145°C, and then dry The oats are sent to the pulverizer and passed through an 80-mesh sieve to obtain dehulled oat flour;

[0047] Step 2: Take deionized water that is 4 times the weight of oat flour, add dehulled oat flour to the deionized water, add the formula amount of starch gelatinase and protease, and keep stirring so that the dehulled oat flour dissolves at the same time It is enzymatically hydrolyzed, the stirring temperature is controlled at 55°C, and the stirring speed is controlled at 650r / min to obtain the enzymatic hydrolyzate;

[0048] Step 3: Add the formulated amount of vegetable oil, xylitol, di...

Embodiment 2

[0052] refer to figure 1 As shown, as another preferred embodiment of the present invention, the difference from Embodiment 1 is that a method for preparing whole oat milk includes the following steps;

[0053] Step 1: Weigh the oats, send the oats to the steam cooking furnace for high-temperature cooking, the cooking temperature is controlled at 90°C, send the cooked oats to the drying furnace for drying treatment, and the drying temperature is controlled at 135°C, and then baked The dried oats are sent to the pulverizer, and passed through a 200-mesh sieve to obtain dehulled oat flour;

[0054] Step 2: Weigh deionized water twice the weight of oat flour, add dehulled oat flour into the deionized water, add the formula amount of starch gelatinase and protease, and keep stirring so that the dehulled oat flour dissolves at the same time It is enzymatically hydrolyzed, the stirring temperature is controlled at 60°C, and the stirring speed is controlled at 5500r / min to obtain th...

Embodiment 3

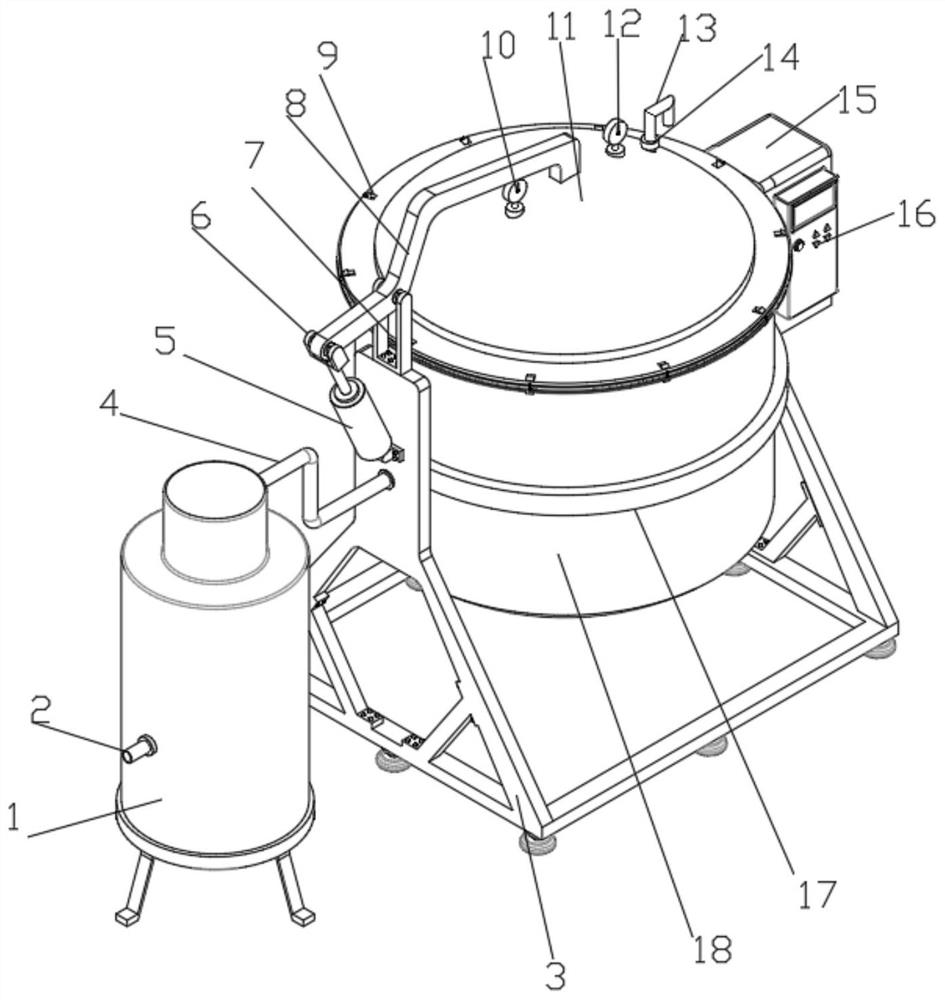

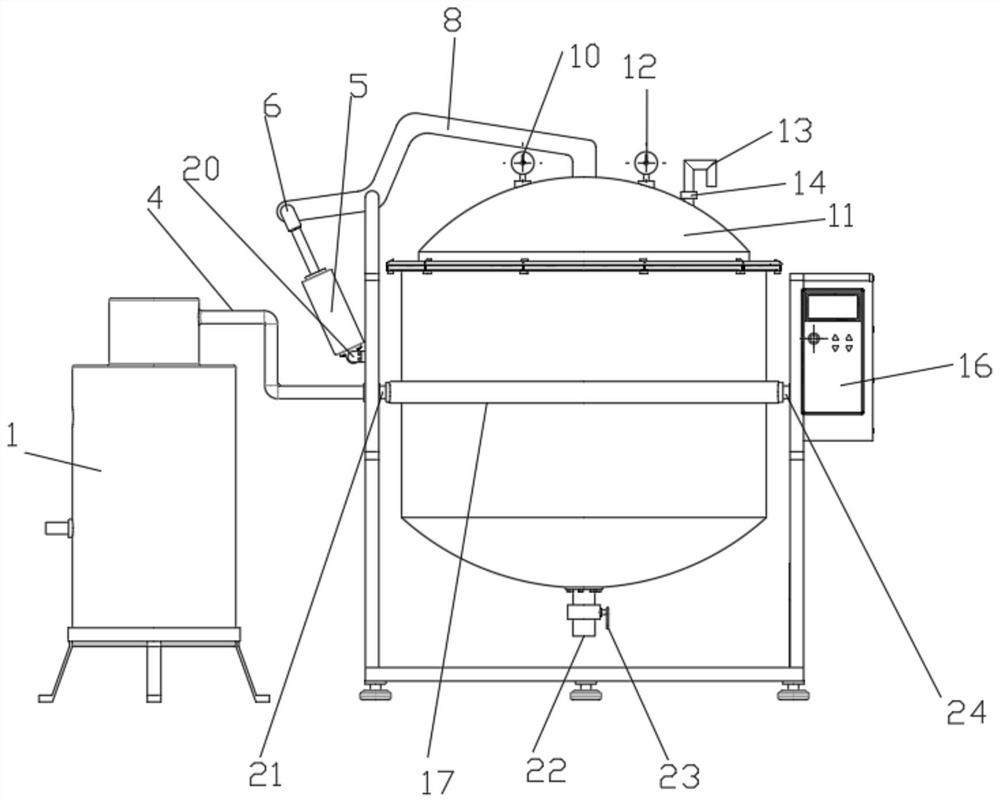

[0060] refer to Figure 2-11 As shown, a whole oat milk preparation device, the preparation device is a steam cooking furnace in step 1, including a steam generator 1 and a support seat 3, the side wall of the support seat 3 is connected with a turning structure, and the turning structure includes a chassis 15, a mounting ring 17. Hollow shaft 21, cross shaft 24, drive motor 26, first bevel gear 27 and second bevel gear 28, support seat 3 has hollow shaft 21 and cross shaft 24 through bearing rotation, hollow shaft 21 and cross shaft 24 A mounting ring 17 is fixedly connected between them, a second bevel gear 28 is fixedly connected to the outer end of the horizontal shaft 24, a side wall of the support base 3 is fixedly connected to an organic case 15, and a drive motor 26 is fixedly connected to the inside of the case 15, and the drive motor 26 The output end is coaxially fixedly connected with a first bevel gear 27, and the first bevel gear 27 is engaged with the second bev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com