High-aroma oolong tea processing method based on tree body abiotic stress

A technology of abiotic stress and processing method, which is applied in the field of high-flavor oolong tea processing, can solve the problems of shortening the processing cycle and achieve the effects of shortening the processing cycle, facilitating market promotion, and having a natural, clear and harmonious aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

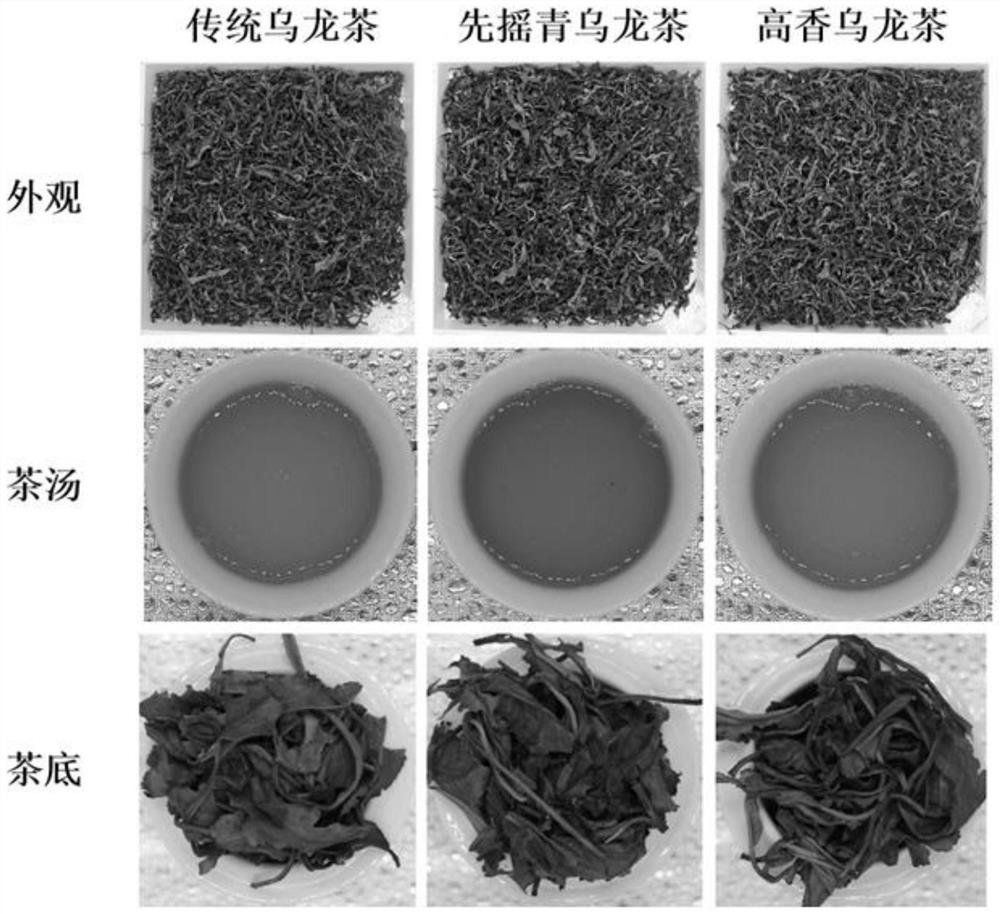

[0030] Embodiment 1 A kind of processing method of high-flavor oolong tea based on tree body abiotic stress

[0031] (1) Mechanical stress treatment of fresh leaf raw materials: select a flat Yinghong No. 9 tea garden (Guangcong No. 1 Provincial Agricultural Science Tea Research Institute Base, Zhongluotan Town, Baiyun District, Guangzhou City), and use physical methods to treat the young leaf buds of the tea tree. Mechanical stress treatment (treatment site such as figure 1 shown), that is, at the same position, use soft materials (such as branches with young leaves, soft plastic or cloth strips, etc.) to swipe the tea tree buds and leaves back and forth 40 times, with an interval of 2 hours as a cycle, and a total of 1 cycle of treatment , causing reddened mechanical damage to the margins of shoot leaves (eg figure 2 As shown), it can be picked;

[0032] (2) Shaking green: after mechanical stress, pick fresh leaves with one bud and two leaves or one bud and three leaves,...

Embodiment 2

[0037] Embodiment 2 A kind of processing method of high-flavor oolong tea based on tree body abiotic stress

[0038] (1) Mechanical stress treatment of fresh leaf raw materials: select a flat Hongyan No. 12 tea garden (Guangcong No. 1 Provincial Agricultural Science Tea Research Institute Base, Zhongluotan Town, Baiyun District, Guangzhou City), and use physical methods to mechanically treat the young leaf buds of the tea tree. Stress treatment, that is, use soft materials (such as branches with young leaves, soft plastic or cloth strips, etc.) to swipe tea tree buds and leaves back and forth 20 times at the same position, with an interval of 2 hours as a cycle, and a total of 2 cycles of treatment. The edge of the young shoots and leaves will be reddened by mechanical damage, and they can be picked;

[0039] (2) Shaking green: after mechanical stress, pick fresh leaves with one bud and two leaves or one bud and three leaves, put the picked fresh leaves indoors for 3 hours, th...

Embodiment 3

[0044] Embodiment 3 A kind of processing method of high-flavor oolong tea based on tree body abiotic stress

[0045] (1) Mechanical stress treatment of fresh leaf raw materials: choose a flat Jinxuan tea garden (Guangcong No. 1 Provincial Agricultural Science Tea Research Institute Base, Zhongluotan Town, Baiyun District, Guangzhou City), and use physical methods to mechanically stress the young leaf buds of tea trees Treatment, that is, use soft materials (such as branches with young leaves, soft plastic or cloth strips, etc.) to swipe tea tree buds and leaves back and forth 60 times at the same position, with an interval of 2 hours as a cycle, and a total of 1 cycle of treatment. The edges of the young shoots and leaves produce reddish mechanical damage, which can be picked;

[0046] (2) Shaking green: after mechanical stress, pick fresh leaves with one bud and two leaves or one bud and three leaves, put the picked fresh leaves indoors for 1 hour, put them in a shaker cage a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com