Preparation method of high-entropy monatomic catalyst

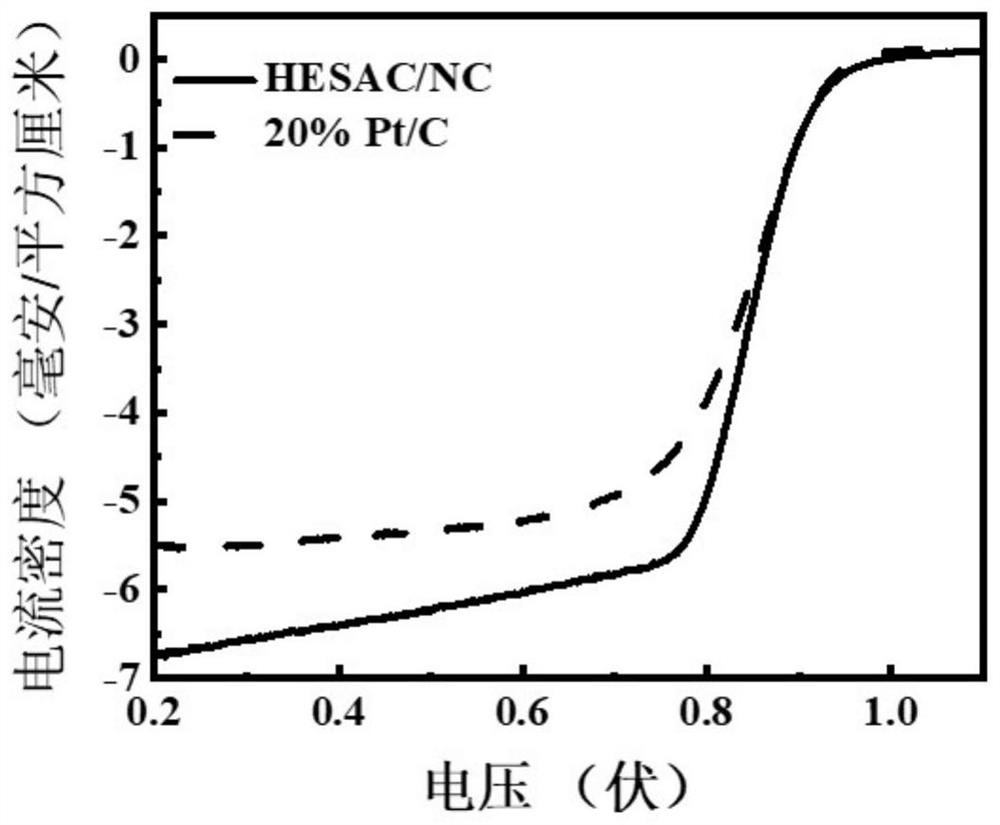

A catalyst and atomic technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve the effects of convenient operation, good single-atom dispersion and stability, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The present invention provides a kind of preparation method of high-entropy single-atom catalyst, and the method comprises:

[0027] Preparation of different metal precursors: respectively dissolving the first carrier precursor and different metal precursors in an acid solution and evaporating to dryness to obtain mixed materials corresponding to different metal precursors, and sintering the evaporated mixed materials to obtain different metal precursors; there are at least five metal precursors;

[0028] Preparation of high-entropy single-atom catalysts: dissolving the second carrier precursor and the metal precursor in an alkaline buffer solution and stirring for 12-36 hours, suction filtering and drying to obtain the catalyst precursor after the stirring is completed, and the catalyst High-entropy single-atom catalysts can be obtained by sintering the precursors.

[0029] Wherein, the first carrier precursor is a carbonitride, and the first carrier precursor include...

Embodiment 1

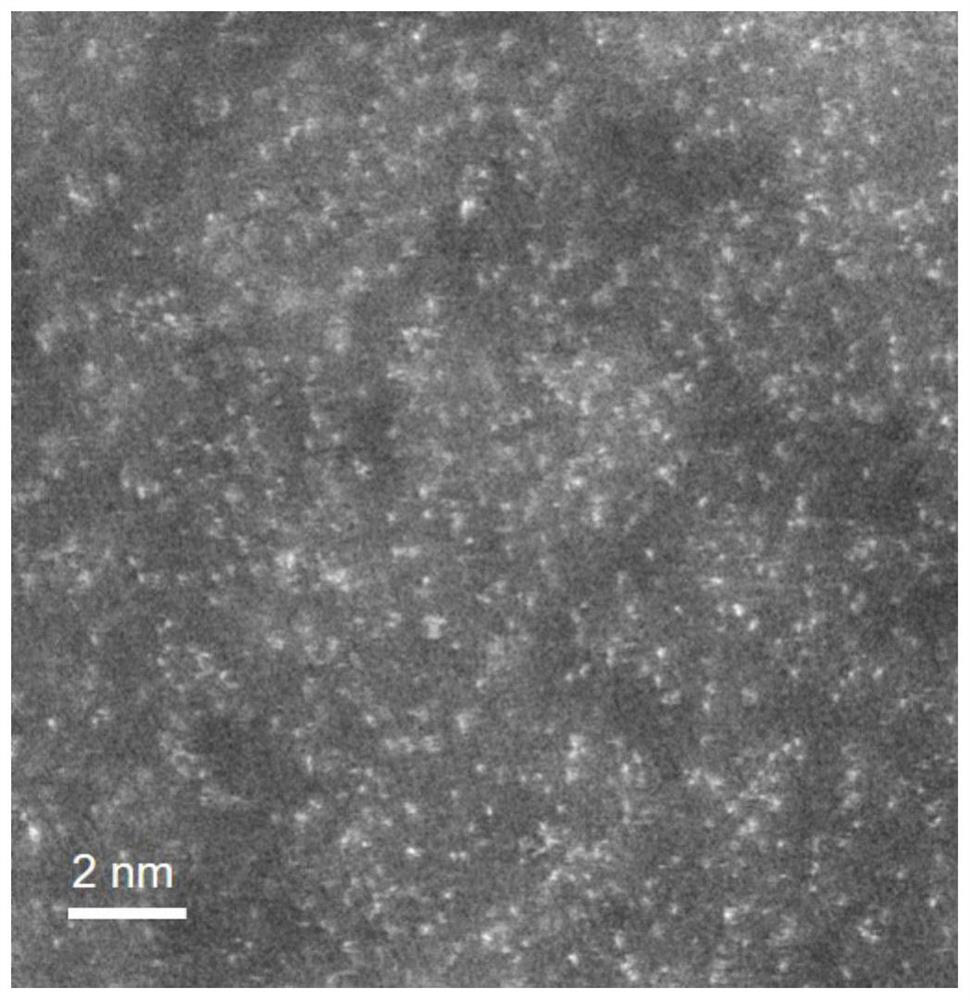

[0047] A preparation method of a high-entropy single-atom catalyst, the high-entropy single-atom catalyst is a five-element high-entropy single-atom catalyst (HEASC-FeCoNiCuMn / NC), the preparation method comprising:

[0048] S1. Prepare different metal precursors respectively;

[0049] S11, the preparation of metal precursor Fe: first use hydrochloric acid solution (30ml HCl+120ml ultrapure water) to dissolve melamine (9g) and ferric chloride (0.1g), after melamine and ferric chloride dissolve completely, obtain mixed solution, in Evaporate the mixed solution at 110°C to obtain the mixed material, and then place the evaporated mixed material in a muffle furnace for sintering to obtain the metal precursor Fe; wherein, the temperature of the muffle furnace is 550°C, and the heating rate is 5°C / min, holding time: 120 minutes.

[0050] S12, the preparation of metal precursor Co: first use hydrochloric acid solution (30ml HCl+120ml ultrapure water) to dissolve melamine (9g) and c...

Embodiment 2

[0064] A preparation method of a high-entropy single-atom catalyst, the high-entropy single-atom catalyst is a seven-member high-entropy single-atom catalyst (HEASC-FeCoNiCuMnCrPt / NC), the preparation method comprising:

[0065] S1. Prepare different metal precursors respectively;

[0066] S11, the preparation of metal precursor Fe: first use hydrochloric acid solution (30ml HCl+120ml ultrapure water) to dissolve melamine (9g) and ferric chloride (0.1g), after melamine and ferric chloride dissolve completely, obtain mixed solution, in Evaporate the mixed solution at 110°C to obtain the mixed material, and then place the evaporated mixed material in a muffle furnace for sintering to obtain the metal precursor Fe; wherein, the temperature of the muffle furnace is 550°C, and the heating rate is 5°C / min , Holding time: 120 minutes.

[0067] S12, the preparation of metal precursor Co: first use hydrochloric acid solution (30ml HCl+120ml ultrapure water) to dissolve melamine (9g) a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com