Welding positioning device and method for double-right-angle support assembly of aero-engine

An aero-engine and welding positioning technology, which is applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of welding deformation and low efficiency, improve welding deformation, meet the requirements of shape and position tolerance, and ensure that the benchmark remains unchanged Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] Below in conjunction with accompanying drawing and specific embodiment content of the present invention is described in further detail:

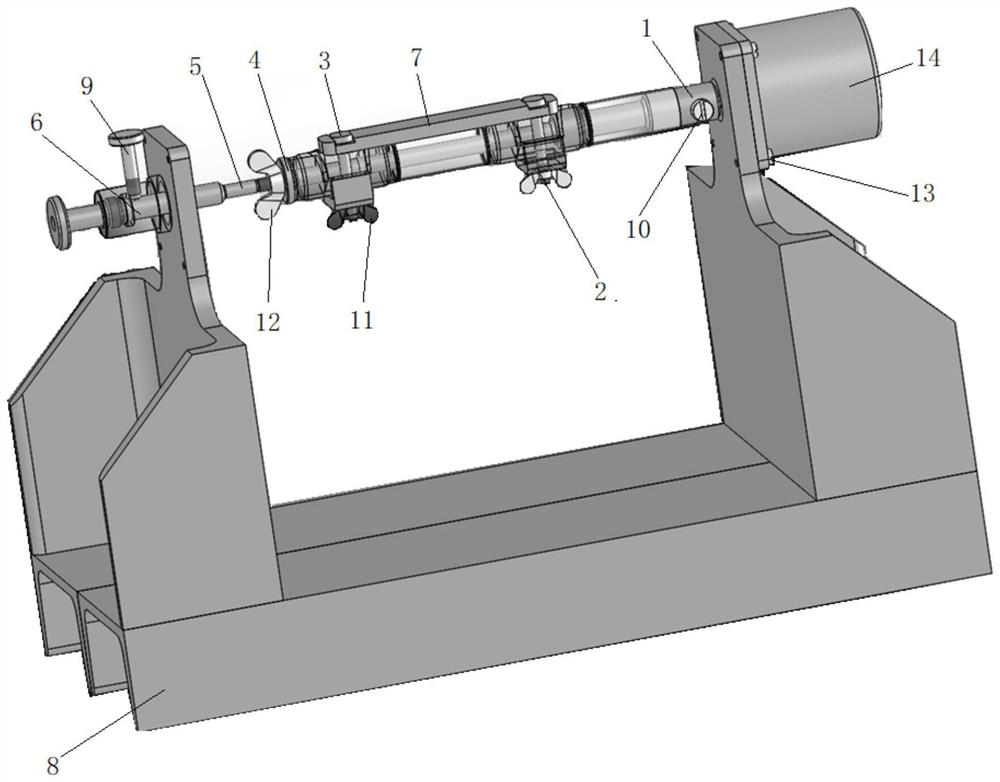

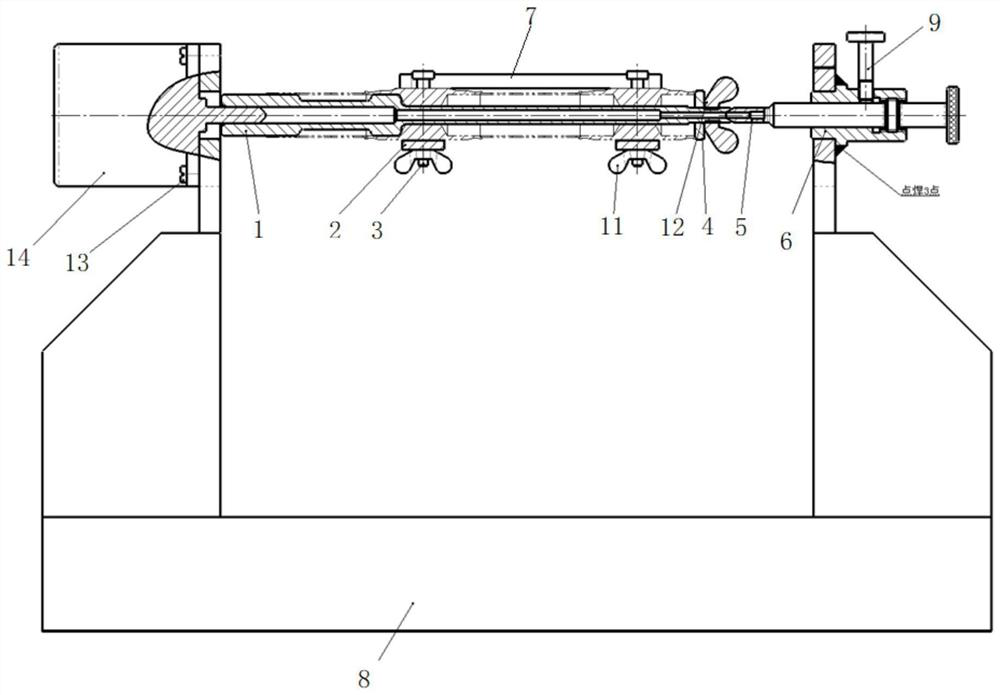

[0076] A welding positioning device for a double right-angle support assembly of an aero-engine comprises two sets of tooling, a support rod welding fixture and a front and rear support plate welding fixture.

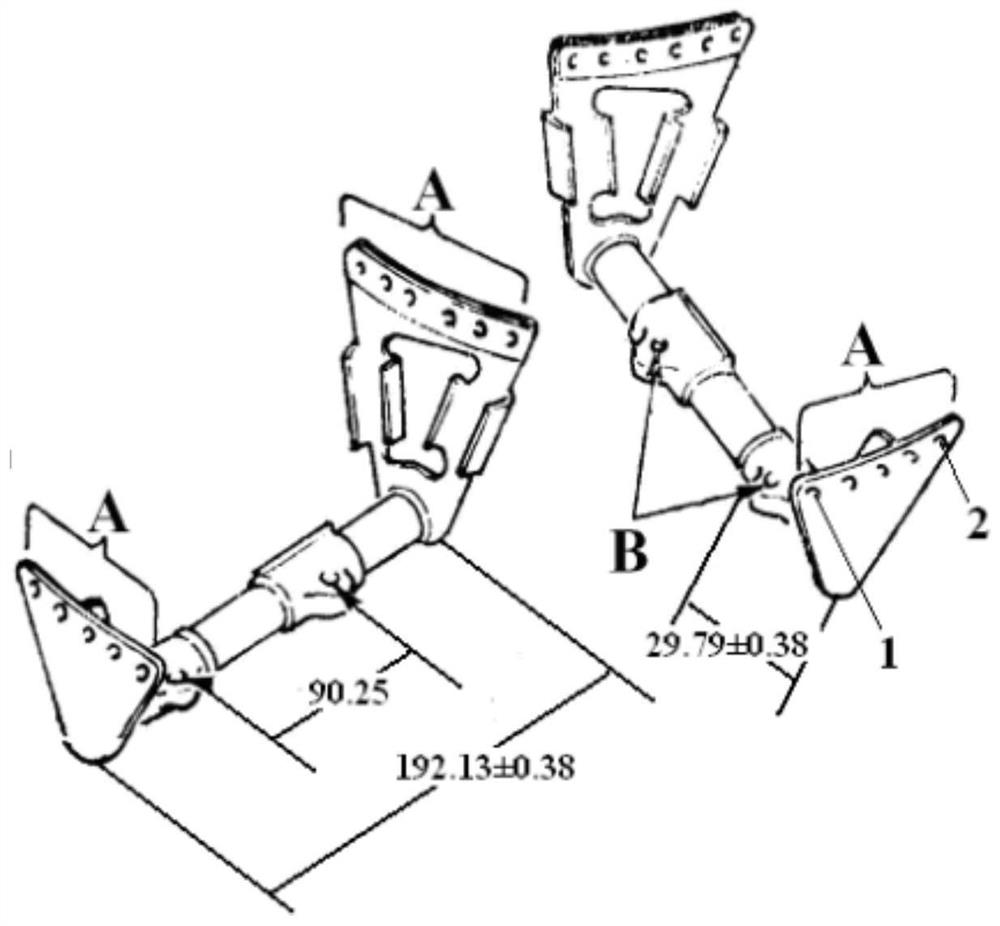

[0077] Such as Figure 2-Figure 6 As shown, the support rod welding fixture is composed of 14 parts, including the first mandrel 1, the pressure plate 2 (2 pieces), the pin 3 (2 pieces), the washer 4, the ejector pin 5, the guide sleeve 6, the ruler 7, First base 8, set screw 9, first slotted cylinder head screw 10, first wing nut 11 (2 pieces), second wing nut 12, second slotted cylinder head screw 13 (4 pieces), motor 14. It is used to weld the support bar which is composed of pipe fitting 1, forging part 1, pipe fitting 2 and forging part 2 alternately.

[0078] Pressing plate 2, pin 3, flat ruler 7, first wing nut 11 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com