Preparation method of nitrogen-doped graphene oxide-supported carbon nanotubes and fe/zif8 composites

A technology of carbon nanotubes and composite materials, which is applied in the field of material chemistry, can solve the problems of high-temperature transition metals being easy to agglomerate, and achieve the effects of reducing agglomeration, high use value, and harmless to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

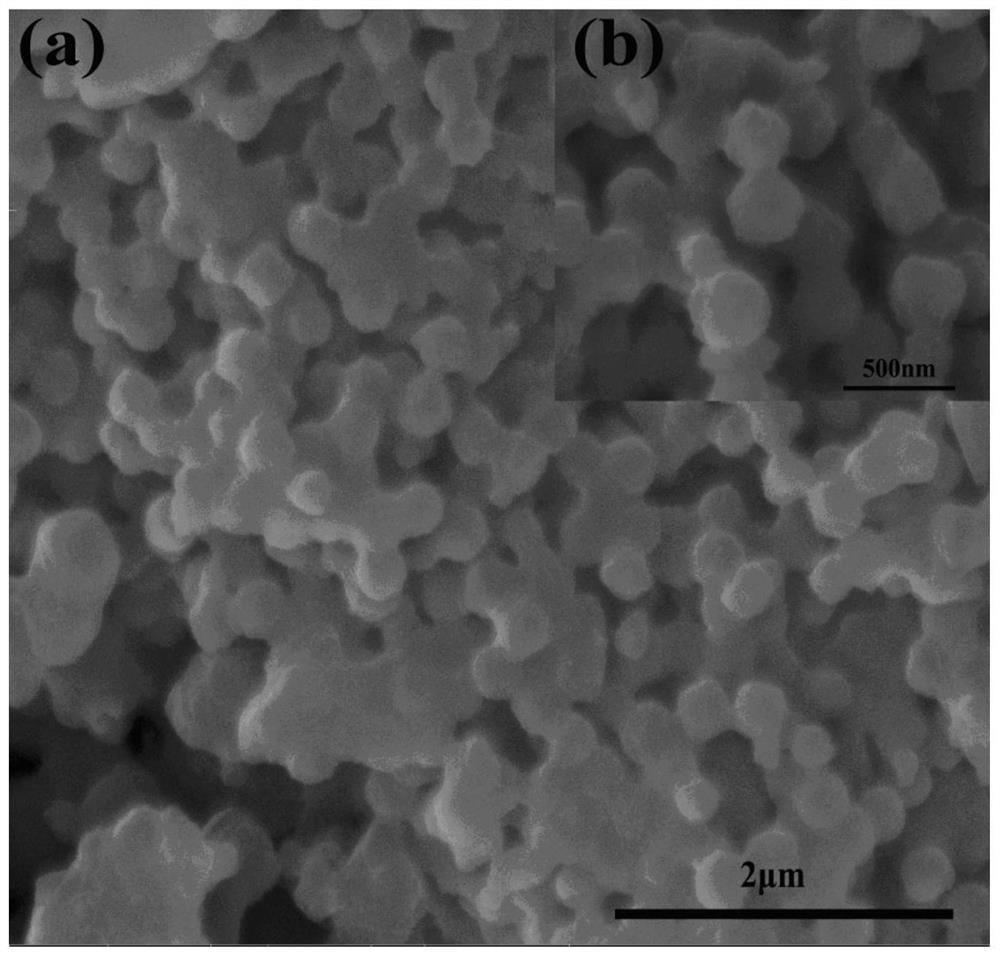

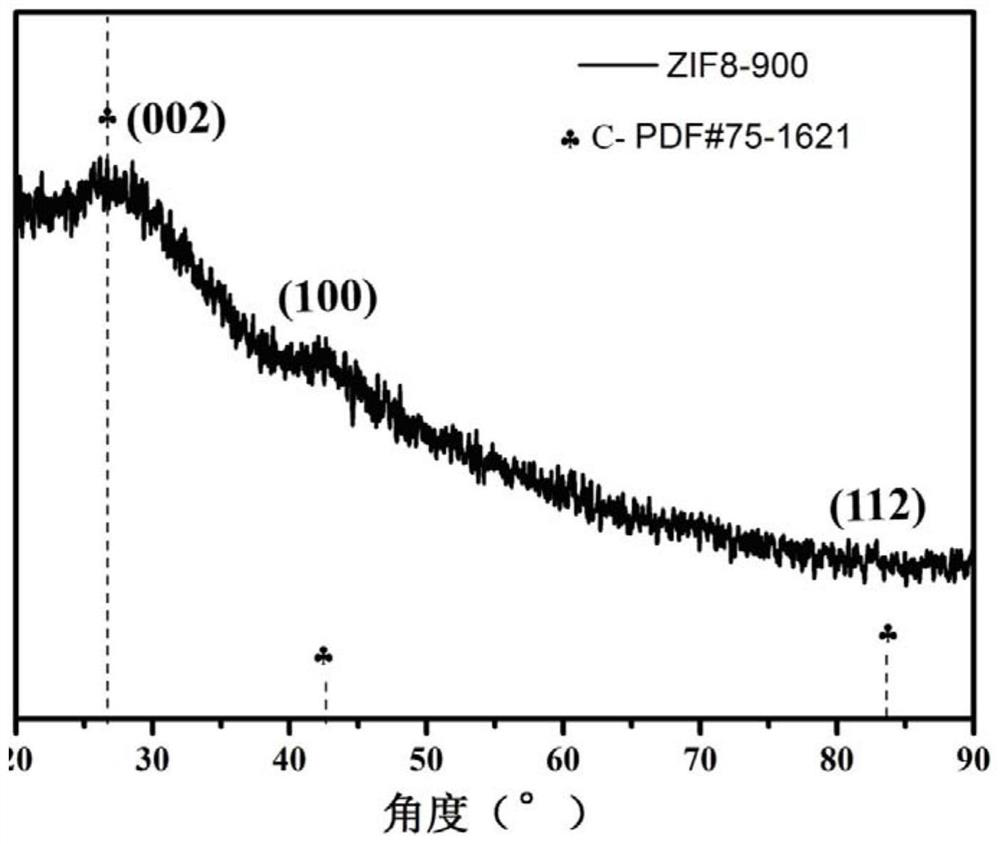

[0037] Preparation method of sample ZIF8-900:

[0038] 1) Dissolve 4g of dimethylimidazole in 25mL of methanol, stir for 10min to obtain a dimethylimidazole solution, then take 1g of Zn(NO) 3 ) 6H 2 O was dissolved in 10 mL of methanol and stirred for 10 min to obtain Zn(NO 3 ) 6H 2 O solution, slowly add dimethylimidazole solution dropwise to Zn(NO 3 ) 6H 2 O solution (dropwise added for 5min) to obtain a uniform milky white mixed solution, the milky white mixed solution was continuously stirred at room temperature for 12h, centrifuged at 12000rpm for 20min, washed with methanol and dried at 60°C to obtain ZIF8.

[0039] 2) Step 2) Put the ZIF8 powder in the crucible, cover the crucible, calcine under Ar conditions, heat the tube furnace to 550°C at 3°C / min and keep it for 2h; then heat up to 3°C / min. The temperature was kept at 900 °C for 2 h, and finally the furnace was naturally cooled to room temperature under the protection of Ar to obtain the sample ZIF8-900.

Embodiment 2

[0041] Preparation method of sample Fe / ZIF8-900:

[0042] 1) Step 1) Dissolve 4 g of dimethyl imidazole in 25 mL of methanol, stir for 10 min to obtain a dimethyl imidazole solution, and then take 1 g of Zn(NO) 3 ) 6H 2 O was dissolved in 10 mL methanol and stirred for 10 min to obtain Zn(NO 3 ) 6H 2 O solution, slowly add dimethylimidazole solution dropwise to Zn(NO 3 ) 6H 2 O solution (dropwise added for 5 min) to obtain a uniform milky white mixed solution, the milky white mixed solution was continuously stirred at room temperature for 12 h, centrifuged at 12000 rpm for 20 min, washed with methanol and dried at 60 °C to obtain ZIF8. Then take 120mg ZIF8 sample, add it into 5mL methanol, stir for 15min to obtain solution A, then mix 5mL methanol with 60mg anhydrous FeCl 3 Mix and stir for 15 min to obtain solution B, mix and stir solution A and solution B for 12 h, centrifuge at 12000 rpm for 20 min, wash with methanol and dry at 60 °C for 5 h to obtain Fe / ZIF8 powder. ...

Embodiment 3

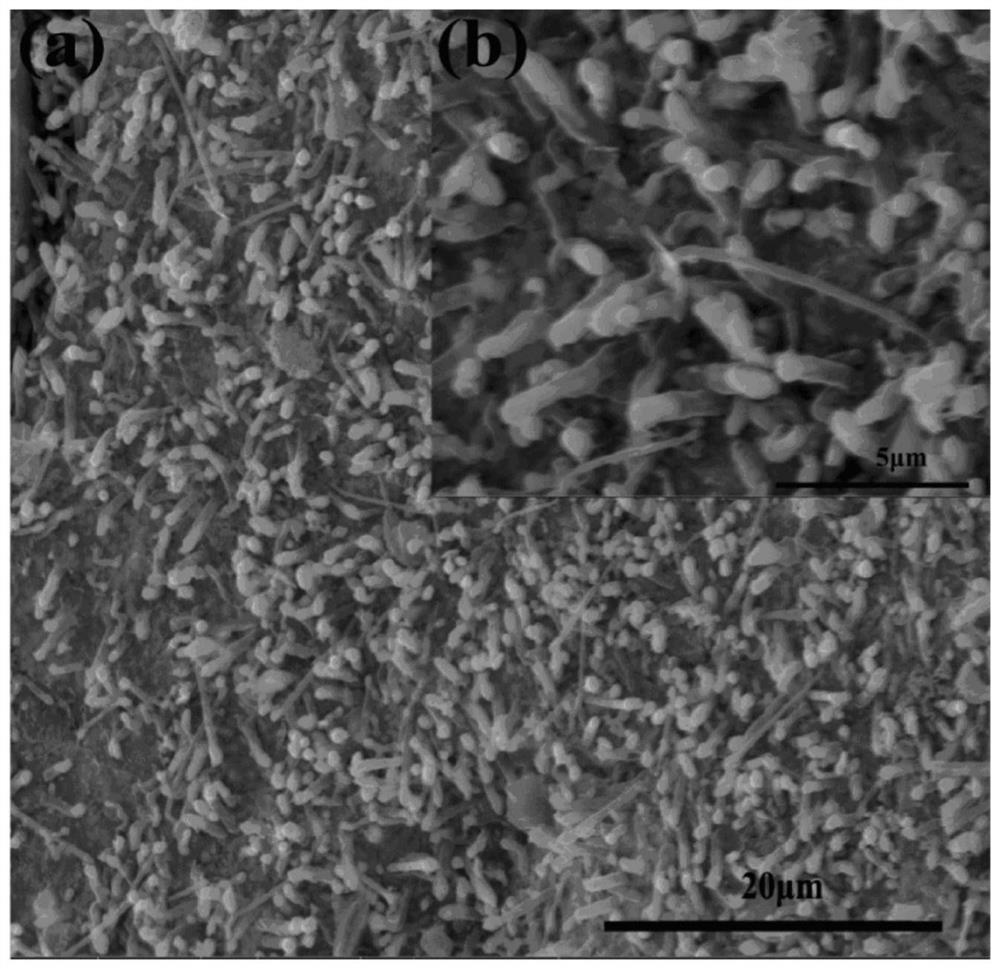

[0045] Preparation method of nitrogen-doped graphene oxide negative carbon nanotube Fe / ZIF8 (N-GO@Fe / ZIF8-900) composite material:

[0046]1) Add 3g urea to 50mL (1mg / mL) graphene oxide, ultrasonicate for 2h to obtain a uniform brown solution, put the brown solution in a refrigerator at -80°C for 12h to obtain a brown solid, and place the brown solid in freeze-drying Dry in the machine for 48h to obtain brown powder.

[0047] 2) Dissolve 4g of dimethylimidazole in 25mL of methanol, stir for 10min to obtain a dimethylimidazole solution, then take 1g of Zn(NO) 3 ) 6H 2 O was dissolved in 10 mL methanol and stirred for 10 min to obtain Zn(NO 3 ) 6H 2 O solution, slowly add dimethylimidazole solution dropwise to Zn(NO 3 ) 6H 2 O solution (dropwise added for 5 min) to obtain a uniform milky white mixed solution, the milky white mixed solution was continuously stirred at room temperature for 12 h, centrifuged at 12000 rpm for 20 min, washed with methanol, and then dried at 60 °...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com