A nickel-based hierarchical structure integrated electrode for electrolyzing water and its preparation method

A hierarchical structure, electrolysis of water technology, applied in the direction of electrodes, electrolysis components, electrolysis process, etc., can solve the problems of low activity, low output, high consumption, etc., achieve the effect of multiple active sites, shorten the transmission length, and improve the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

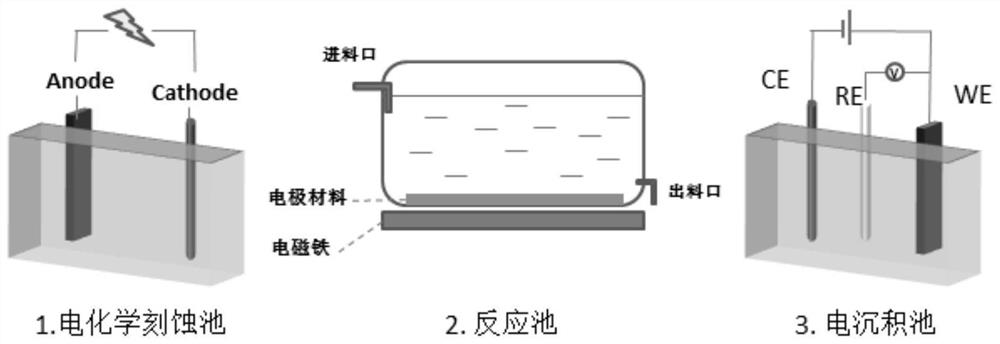

[0026] 1. Preparation of rough surface nickel mesh (E-NM)

[0027] Will measure 1.5 x 1cm 2 The commercial nickel mesh (NM) was put into 3M HCl electrolyte solution, and a two-electrode system was adopted, with NM as the positive electrode and graphite rod as the negative electrode, and the chronoamperometry it was used for electrochemical etching, and the set voltage was 1V. Properties of the obtained E-NM electrodes under etching time. Specifically, the electrochemical etching time is 30-600s, and the performance is optimal when the electrochemical etching time is 100s.

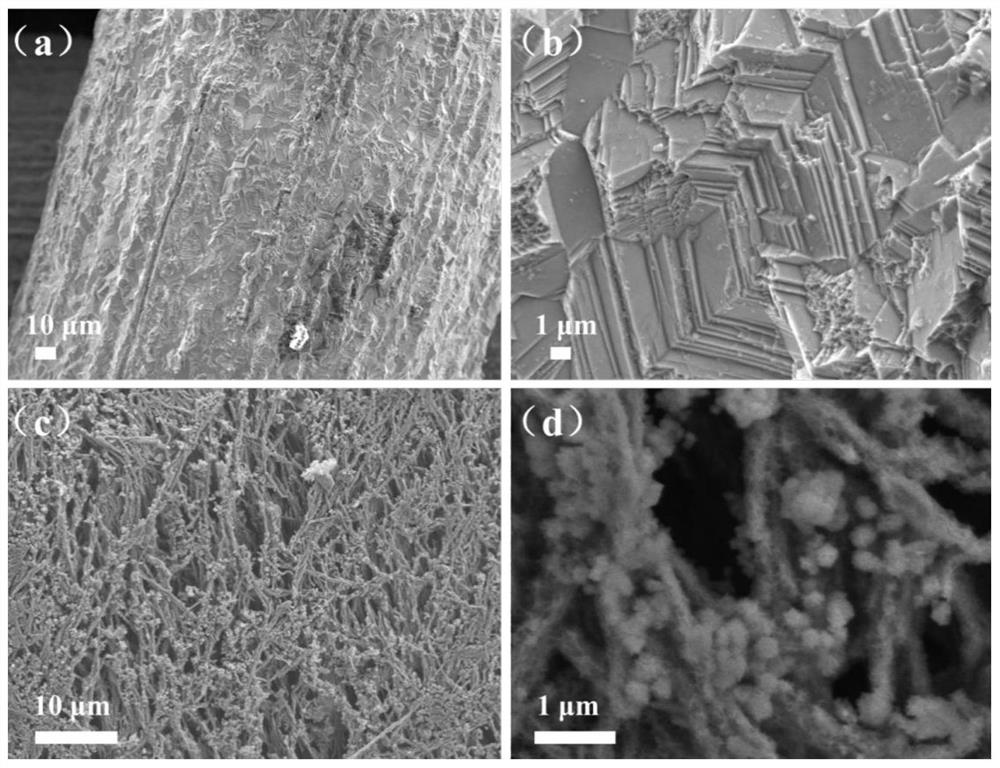

[0028] figure 2 a and 2b are SEM images of NM before and after electrochemical etching. It can be seen from the figure that the surface of the nickel mesh fiber changes from smooth to rough after electrochemical etching, which is easy to nucleate during the subsequent growth of nickel nanowires.

[0029] 2. Preparation of nickel nanowire arrays (Ni NWs / E-NM)

[0030] (1), configure solution A and solut...

Embodiment 2

[0037] 1. Preparation of rough surface nickel mesh (E-NM)

[0038] Specifically, the steps are the same as those in Example 1

[0039] 2. Preparation of nickel nanowire arrays (Ni NWs / E-NM)

[0040] Specifically, the steps are the same as those in Example 1

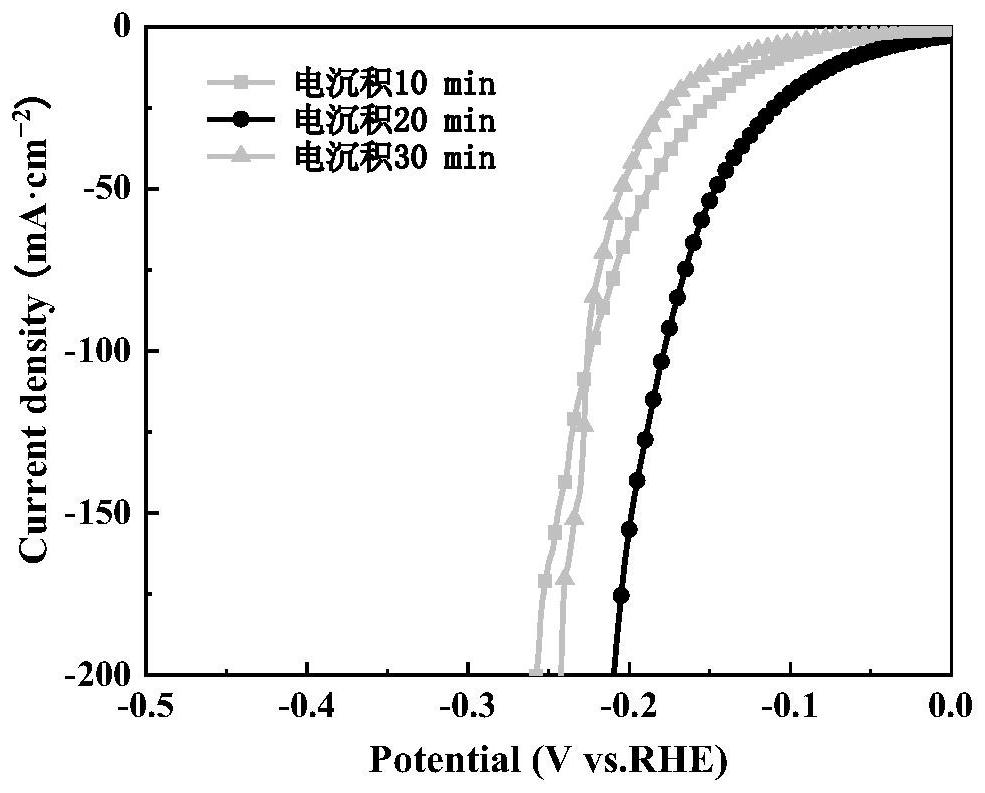

[0041] 3. Preparation of electrode materials (NiCo / Ni NWs / E-NM)

[0042] Using the prepared Ni NWs / E-NM as the precursor, a three-electrode electrochemical cell was used, with Ni NWs / E-NM as the working electrode, platinum sheet as the counter electrode, and Ag / AgCl as the reference electrode, containing 0.25M NiSO 4 ·6H 2 O, 0.25M CoSO 4 ·6H 2 O, 0.2MNa 2 SO 4 and 0.5M H 3 BO 3 The solution is an electrolyte, and under the condition of a constant voltage of -1V, the electrodeposition time is adjusted to prepare the best sample NiCo / Ni NWs / E-NM.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com