A kind of conductive thermal conductive polymer fiber and preparation method thereof

A technology of electric conduction, heat conduction and polymer, which is applied in the manufacture of conductive/antistatic filaments, conjugated synthetic polymer artificial filaments, fiber treatment, etc., can solve the problem that the metal silver layer cannot be bonded with fibers, etc., to increase the metal silver content , increase the roughness, increase the effect of the anchor point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

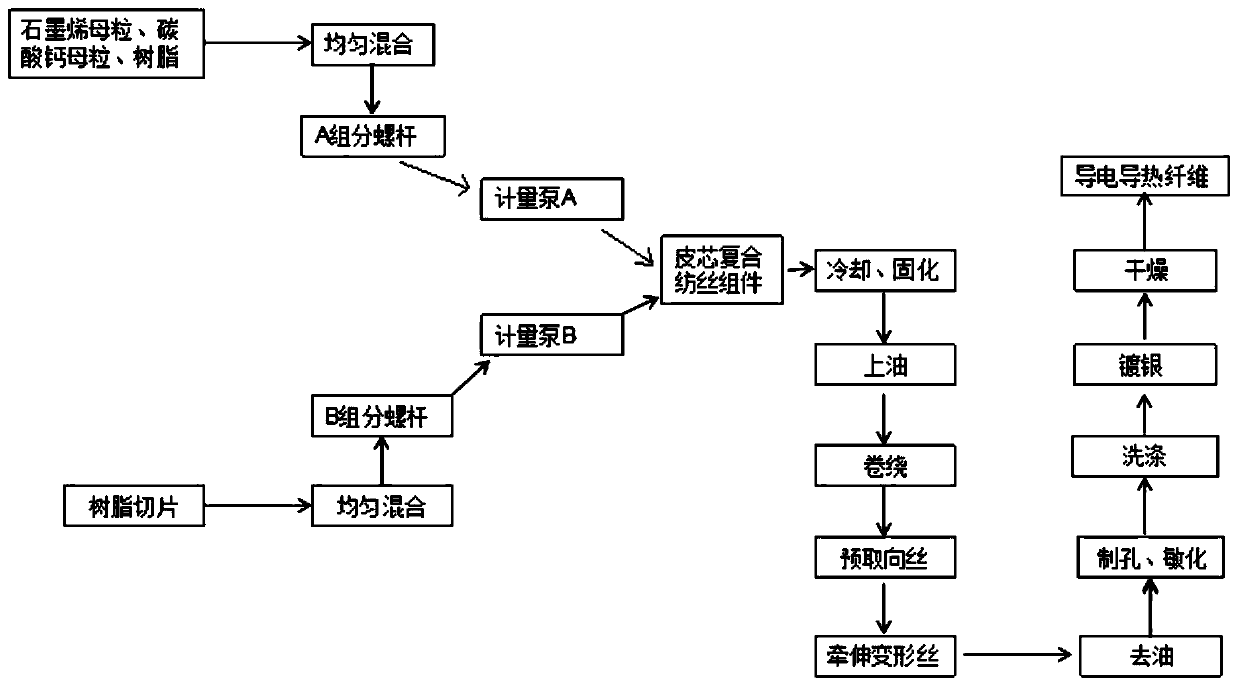

[0063] Another aspect of the present invention relates to a method for preparing an electrically and thermally conductive polymer fiber, see for details figure 1 The flow chart includes the following steps:

[0064] (a) Graphene masterbatch, calcium carbonate masterbatch and polymer resin are blended as A component, and polymer resin is used as B component, and described A component is used as skin layer, and described B component is used as core layer, both Composite spinning is carried out to obtain bi-component composite fibers after texturing;

[0065] (b) remove the oil agent and impurities on the surface of the two-component composite fiber;

[0066] (c) Hole making and sensitization treatment on the fiber surface;

[0067] (d) plating a conductive metal layer to obtain the conductive and thermally conductive polymer fibers.

[0068] The preparation method of the conductive and heat-conducting polymer fiber provided by the present invention only adds graphene and calc...

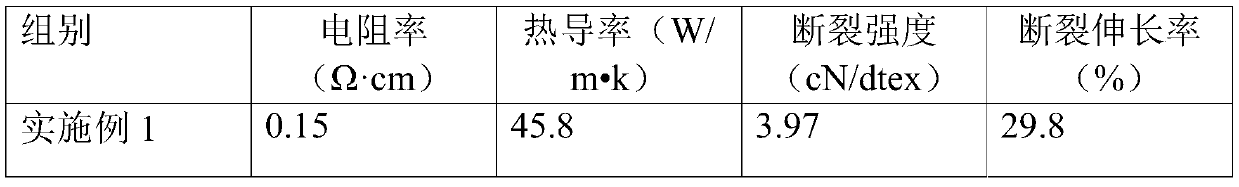

Embodiment 1

[0096] Preparation of 75D / 48F Conductive and Thermally Conductive Polyester Fiber

[0097] (1) Preparation of sheath-core bicomponent polyester fiber

[0098] Graphene masterbatch, calcium carbonate masterbatch, and polyester chips are blended in a certain proportion as component A; polyester chips are used as component B. After the components A and B are dried in a vacuum drum drying oven, the two-component composite spinning technology is adopted, in which component A uses a cortical screw and component B uses a core screw. The temperature of the component A screw in the four zones is 270°C, 284°C, 282°C, and 282°C, and the temperature of the component B screw in the four zones is 270°C, 287°C, 285°C, and 285°C.

[0099] The two-component raw materials are melted by a screw, extruded, cooled and solidified, oiled, and wound to obtain a sheath-core type two-component polyester pre-oriented yarn. The volume ratio of the skin layer and the core layer is 1:1.2. Among them, the...

Embodiment 2

[0110] Preparation of 70D / 48F Conductive and Thermally Conductive Polyamide Fiber

[0111] (1) Preparation of sheath-core bicomponent polyamide fiber

[0112] Graphene masterbatch, calcium carbonate masterbatch and polyamide chips are blended in a certain proportion as component A; polyamide chips are used as component B. After the components A and B are dried in a vacuum drum drying oven, the two-component composite spinning technology is adopted, in which component A uses a cortical screw and component B uses a core screw. The temperature of the component A screw in the four zones is 250°C, 264°C, 262°C, and 262°C, and the temperature of the component B screw in the four zones is 250°C, 267°C, 265°C, and 265°C.

[0113] The two-component raw materials are melted by a screw, extruded, cooled and solidified, oiled, and wound to obtain a sheath-core type two-component polyester pre-oriented yarn. The volume ratio of the skin layer and the core layer is 1:1.5. Among them, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com