Bushing plate for drawing low-dielectric high-temperature glass fiber

A glass fiber, low dielectric technology is applied in the field of low dielectric and high temperature glass fiber drawing bushings, which can solve the problems that the existing product quality requirements cannot be met, the bushings cannot meet the high temperature requirements, and the service life of the bushings is shortened. To achieve the effect of optimizing the distribution of leak nozzles, reducing the deviation of tension and increasing the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

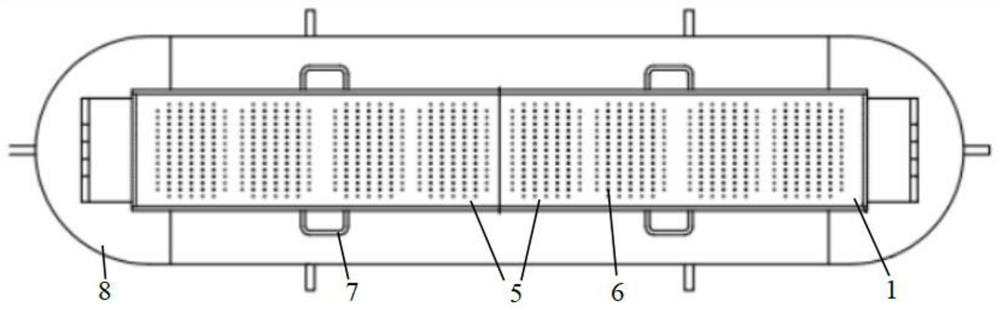

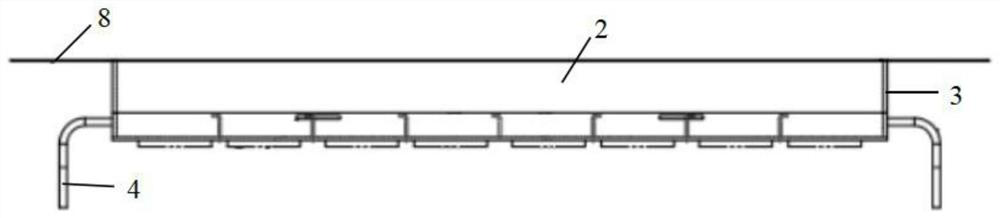

[0032] like figure 1 , 2 Shown is a bushing for low-dielectric high-temperature glass fiber drawing. The main body of the bushing is composed of a platinum-rhodium alloy, wherein the platinum metal content is 95%, and the rhodium metal content is 5%. The main body of the leakage plate includes a bottom plate 1, two side walls 2 arranged in parallel front and back, and plugs 3 located at the left and right ends. Trough accommodation.

[0033] The lower surface of the bottom plate 1 is provided with eight wire drawing areas 5 separated from each other, and the wire drawing area 5 is provided with leaking nozzles 6 distributed in a rectangular array. Formed by side stretching, the leakage nozzle 6 is hollow columnar.

[0034] One side of the plug 3 is connected with a downwardly bent electrode 4, through which the electrode 4 can be energized to make the plug 3 generate heat and adjust the temperature of the molten glass contained in the groove-shaped accommodation space, ther...

Embodiment 2

[0046] like figure 1 , 2 Shown is a bushing for low-dielectric high-temperature glass fiber drawing. The main body of the bushing is composed of platinum-rhodium alloy, wherein the platinum metal content is 92%, and the rhodium metal content is 8%. The main body of the leakage plate includes a bottom plate 1, two side walls 2 arranged in parallel front and back, and plugs 3 located at the left and right ends. Trough accommodation.

[0047]The lower surface of the bottom plate 1 is provided with eight wire drawing areas 5 separated from each other, and the wire drawing area 5 is provided with leaking nozzles 6 distributed in a rectangular array. Formed by side stretching, the leakage nozzle 6 is hollow columnar.

[0048] One side of the plug 3 is connected with a downwardly bent electrode 4, through which the electrode 4 can be energized to make the plug 3 generate heat and adjust the temperature of the molten glass contained in the groove-shaped accommodation space, thereby...

Embodiment 3

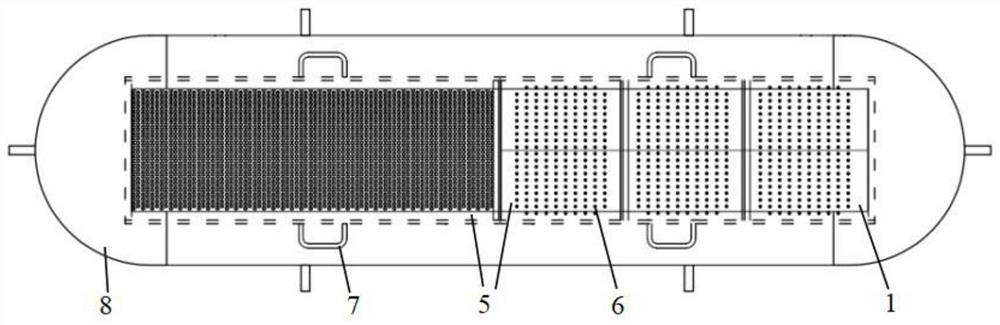

[0060] like image 3 , 4 Shown is a bushing for low-dielectric high-temperature glass fiber drawing. The main body of the bushing is composed of platinum-rhodium alloy, wherein the platinum metal content is 90%, and the rhodium metal content is 10%. The main body of the leakage plate includes a bottom plate 1, two side walls 2 arranged in parallel front and back, and plugs 3 located at the left and right ends. Trough accommodation.

[0061] The lower surface of the bottom plate 1 is provided with six wire drawing areas 5 separated from each other, and the wire drawing area 5 is provided with leak nozzles 6 distributed in a rectangular array. Formed by side stretching, the leakage nozzle 6 is hollow columnar.

[0062] One side of the plug 3 is connected with a downwardly bent electrode 4, through which the electrode 4 can be energized to make the plug 3 generate heat and adjust the temperature of the molten glass contained in the groove-shaped accommodation space, thereby im...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com