High-wear-resistance rubber-based composite material and preparation method thereof

A composite material and rubber-based technology, applied in the field of polymer composite materials, can solve the problems of composite materials such as stretching, tearing and wear resistance, so as to improve chemical bonding ability, improve mechanical properties and wear resistance, Strong tear resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

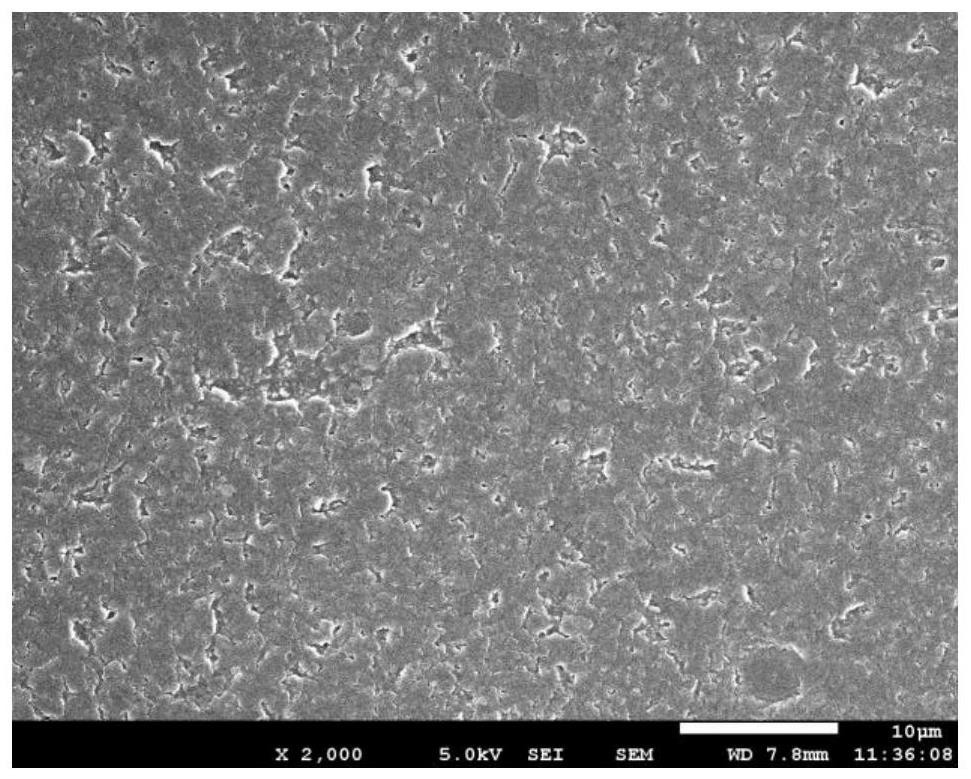

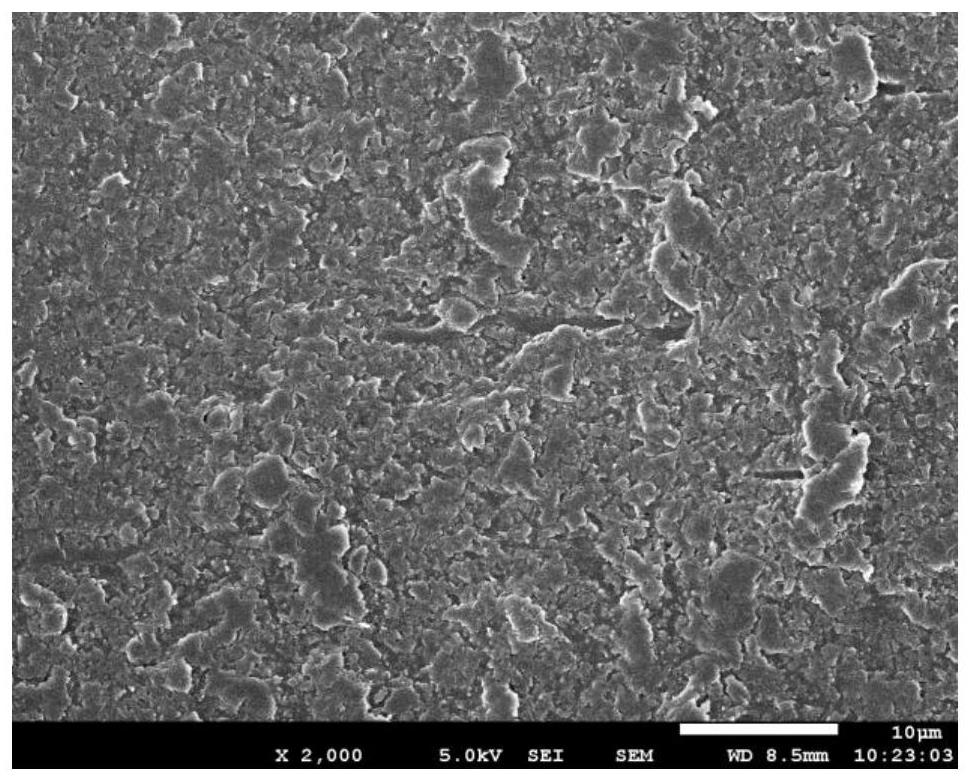

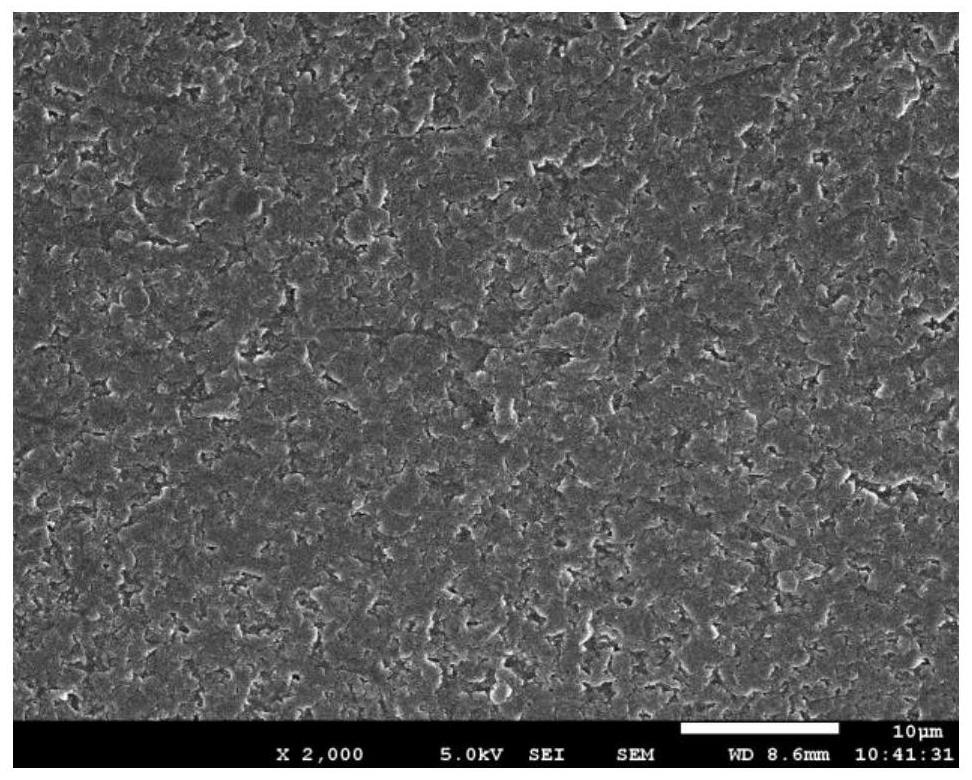

Image

Examples

Embodiment 1

[0053] 1. Preparation of aramid pulp treated with ionic liquid ethanol solution

[0054] (1) Add 1-propenyl-3-vinylimidazolium chloride salt (structure as follows) ionic liquid into ethanol, and after fully dissolving, obtain a concentration of 0.222g / L ionic liquid ethanol solution;

[0055] (2) Soak the aramid pulp in the ethanol solution of the ionic liquid, the mass ratio of the ionic liquid to the aramid pulp is 1:100;

[0056] (3) drying the soaked aramid pulp;

[0057]

[0058] 2. Preparation of high wear-resistant rubber composites

[0059](1) 100 parts of nitrile rubber, 5 parts of zinc oxide, 1 part of stearic acid, 1.2 parts of 2,2,4-trimethyl-1,2-dihydroquinoline polymer (TMQ), carbon black N550 40 parts, 10 parts of dioctyl phthalate (DOP), 15 parts of aramid pulp treated with ionic liquid of 1-propenyl-3-vinylimidazolium chloride salt in internal mixer with 90°C as the initial temperature Mixed for 7 minutes to obtain the primary product.

[0060] (2) Add ...

Embodiment 2

[0063] 1. Preparation of aramid pulp treated with ionic liquid ethanol solution

[0064] (1) Add 1-propenyl-3-vinylimidazolium chloride salt (structure as follows) ionic liquid into ethanol, and after fully dissolving, obtain a concentration of 0.222g / L ionic liquid ethanol solution;

[0065] (2) Soak the aramid pulp in the ethanol solution of the ionic liquid, the mass ratio of the ionic liquid to the aramid pulp is 1:100;

[0066] (3) drying the soaked aramid pulp;

[0067]

[0068] 2. Preparation of high wear-resistant rubber composites

[0069] (1) 100 parts of nitrile rubber, 5 parts of zinc oxide, 1 part of stearic acid, 1.2 parts of 2,2,4-trimethyl-1,2-dihydroquinoline polymer (TMQ), carbon black N550 40 parts, 10 parts of dioctyl phthalate (DOP), 10 parts of aramid pulp treated with 1-propenyl-3-vinylimidazolium chloride salt ionic liquid in the internal mixer with 90 ℃ as the initial temperature Mixed for 7 minutes to obtain the primary product.

[0070] (2) Ad...

Embodiment 3

[0073] 1. Preparation of aramid pulp treated with ionic liquid ethanol solution

[0074] (1) 1-allyl-3-methylimidazolium chloride salt (structure is as follows) ionic liquid is added in ethanol, obtain concentration after fully dissolving and be 0.206g / L ionic liquid ethanol solution;

[0075] (2) Soak the aramid pulp in the ethanol solution of the ionic liquid, the mass ratio of the ionic liquid to the aramid pulp is 1:100;

[0076] (3) drying the soaked aramid pulp;

[0077]

[0078] 2. Preparation of high wear-resistant rubber composites

[0079] (1) 100 parts of nitrile rubber, 5 parts of zinc oxide, 1 part of stearic acid, 1.2 parts of 2,2,4-trimethyl-1,2-dihydroquinoline polymer (TMQ), carbon black N550 40 parts, 10 parts of dioctyl phthalate (DOP), 15 parts of aramid pulp treated with 1-allyl-3-methylimidazolium chloride salt ionic liquid in the internal mixer at 90 ° C as the initial The temperature was mixed for 7 minutes to obtain the primary product.

[0080]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com