Water-based environment-friendly antirust aluminum foil punching shear fluid and preparation method thereof

An environmentally friendly, aluminum foil technology, applied in the field of lubricating oil, can solve the problems of strong volatile odor, skin allergies, and high cost, and achieve the effects of strong fluidity, reduced cracking, and extended life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

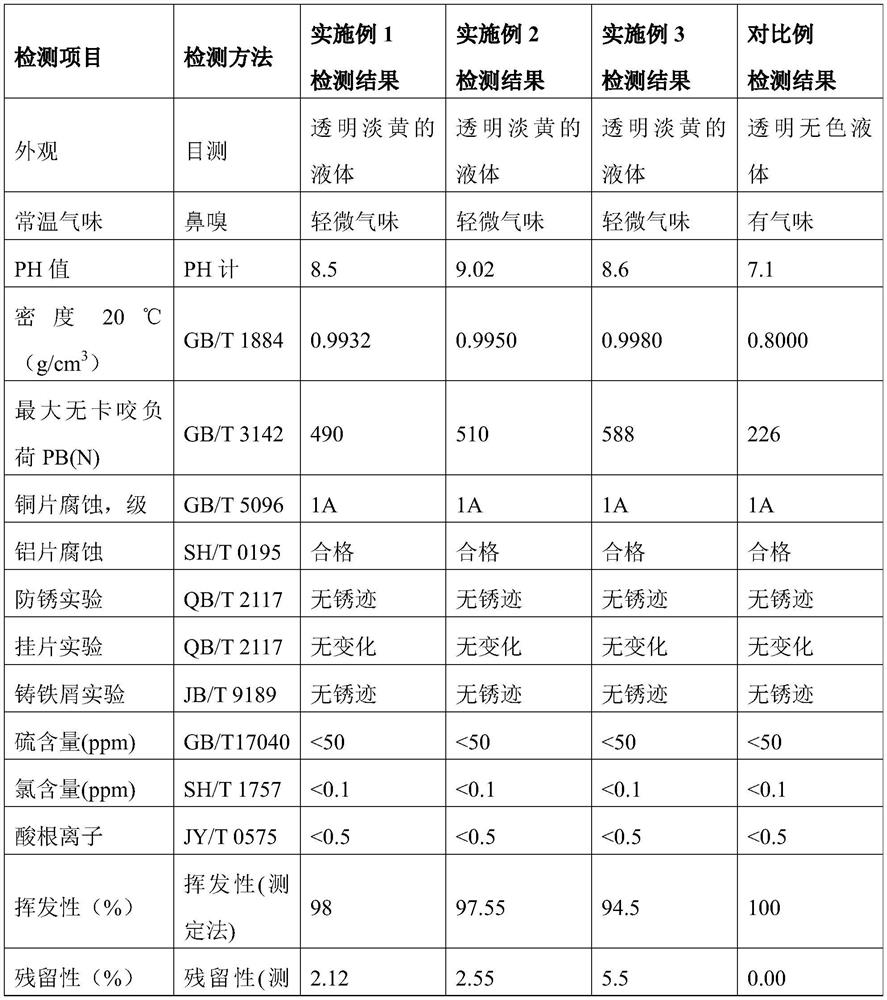

Examples

Embodiment 1

[0037] A water-based environment-friendly antirust aluminum foil punching fluid, by weight percentage, the punching fluid comprises the following components:

[0038] 0.4% lubricant, 0.25% corrosion inhibitor, 0.2% emulsifier, 0.15% bactericide, 0.8% rust inhibitor, 0.3% pH regulator, 0.005% defoamer, and deionized water as the balance.

[0039] Wherein, the added percentage of the lubricant is 0.05% Symarin PE 7310anti-wear EP Additive, 0.20% LUBRHOPHOS LP-700, 0.15% Polyglykol B11 to form a composite lubricant; the corrosion inhibitor is 0.25% Symarin PE 7420Additive; the emulsifying The fungicide is 0.2% TW-20; the bactericide is 0.15% MBM; the rust inhibitor is 0.1% TAT 758-P, 0.1% sebacic acid, 0.1% BASF L190PLUS, 0.5% NEUF 727, forming a composite antirust agent; the pH regulator is triethanolamine; the defoamer is 0.005% silicone defoamer.

[0040] A preparation method of a water-based environment-friendly antirust aluminum foil punching and shearing fluid, comprising ...

Embodiment 2

[0045] A water-based environment-friendly antirust aluminum foil punching fluid, by weight percentage, the punching fluid comprises the following components:

[0046] 0.60% lubricant, 0.75% corrosion inhibitor, 0.20% emulsifier, 0.10% bactericide, 1.00% rust inhibitor, 0.50% PH regulator, 0.01% defoamer, and the balance deionized water.

[0047] Wherein, the additive percentage of the lubricant is 0.30% LUBRHOPHOS LP-700, 0.30% PolyglykolB11 to form a composite lubricant; the corrosion inhibitor is 0.75% Symarin PE 7420 Additive; the emulsifier is 0.20% TW-20; the bactericidal The antirust agent is 0.1% MBM; the antirust agent is 0.15% TAT 758-P, 0.15% sebacic acid, 0.7% NEUF 727, forming a composite antirust agent; the pH regulator is 0.25% diethanolamine, 0.25% three Ethanolamine; the defoamer is 0.01% silicone defoamer.

[0048] A preparation method of a water-based environment-friendly antirust aluminum foil punching and shearing fluid, comprising the steps of:

[0049] ...

Embodiment 3

[0052] A water-based environment-friendly antirust aluminum foil punching fluid, by weight percentage, the punching fluid comprises the following components:

[0053] 1.50% lubricant, 1.50% corrosion inhibitor, 0.50% emulsifier, 0.15% bactericide, 1.00% rust inhibitor, 0.80% PH regulator, 0.01% defoamer, and the balance deionized water.

[0054] Wherein, the additive percentage of the lubricant is 0.10% Symarin PE 7310anti-wear EP Additive, 0.70% LUBRHOPHOS LP-700, 0.70% Polyglykol B11 to form a composite lubricant; the corrosion inhibitor is 1.50% Symarin PE 7420Additive; the emulsifying The bactericide is 0.50% TW-20; the bactericide is 0.15% MBM; the rust inhibitor is 0.15% TAT 758-P, 0.15% sebacic acid, 0.7% NEUF 727, forming a composite rust inhibitor; the PH Regulators are 0.3% diethanolamine and 0.5% triethanolamine; the defoamer is 0.01% organosilicon defoamer.

[0055] A preparation method of a water-based environment-friendly antirust aluminum foil punching and shea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com