Sliding member for internal combustion engine comprising self-test material for monitoring damage to sliding member

A technology for sliding components and internal combustion engines, which is applied in the testing of engines, testing of machine/structural components, engine components, etc., and can solve the problems of insufficient detection of dielectric particles, obstruction of dielectric particles, inability to perform accurate and innovative monitoring, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

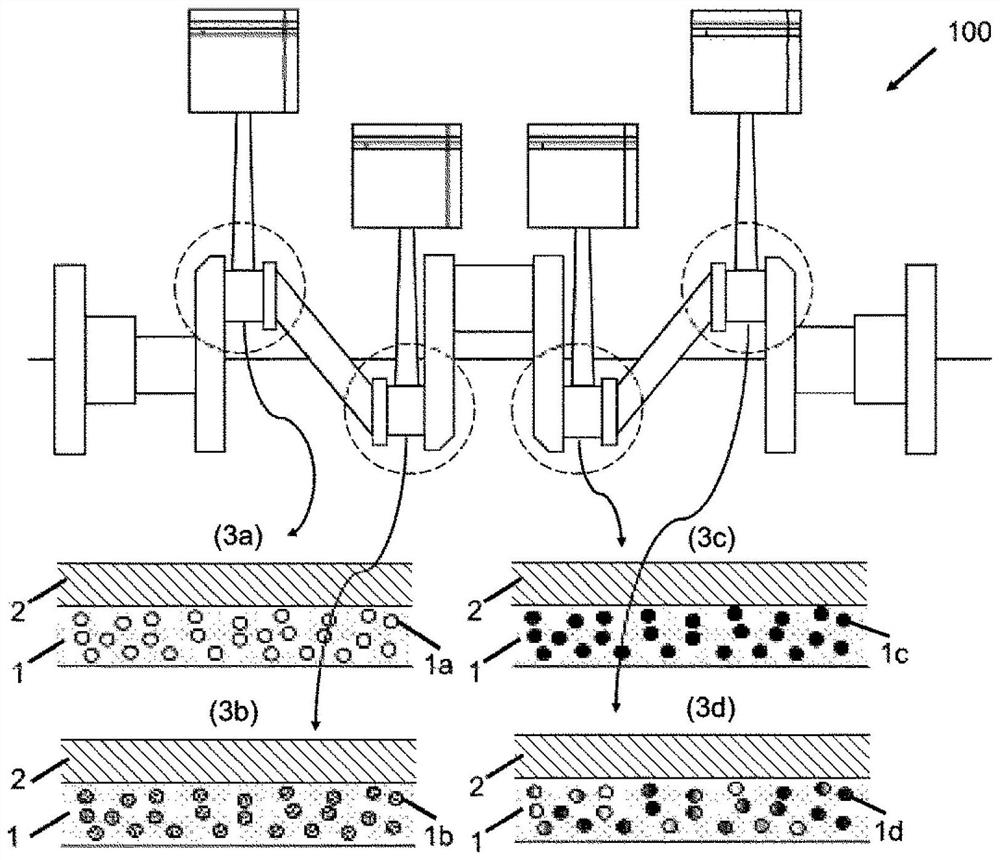

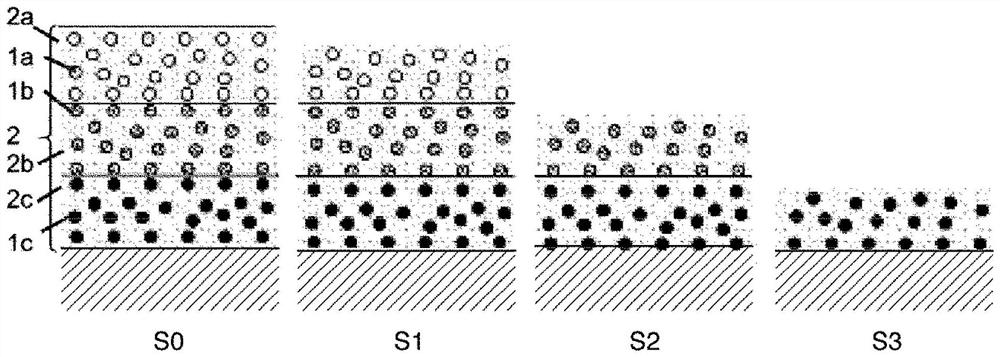

[0039] figure 1 A schematic diagram showing an assembly 100 including a sliding member according to an embodiment of the present invention. As an example, the assembled product 100 is a sliding device having a crankshaft of an internal combustion engine. exist figure 1 In , four different sliding members 3a-3d are shown. Each sliding member includes self-inspection materials 1a to 1d for monitoring damage to the sliding member. Each sliding member has a single-layer or multi-layer structure made of metal, alloy, and / or resin material. In the present embodiment, the self-test materials 1a to 1d are embedded in at least one layer (the lower layer 1 in this example) among the layers constituting the sliding member in a particle state. The self-testing material is composed of at least one material that responds to external energy and exhibits signal properties. In this example, each sliding member includes self-testing materials 1a to 1d that emit mutually different signals. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com