Preparation process of make-up powder containing flat core wood composition

A preparation process, the technology of flat core wood, which is applied in the field of cosmetic powder preparation process, can solve the problems of acne, dull facial skin, and many chemical components, and achieve the goals of accelerating water evaporation, good protection and treatment effect, and improving preparation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

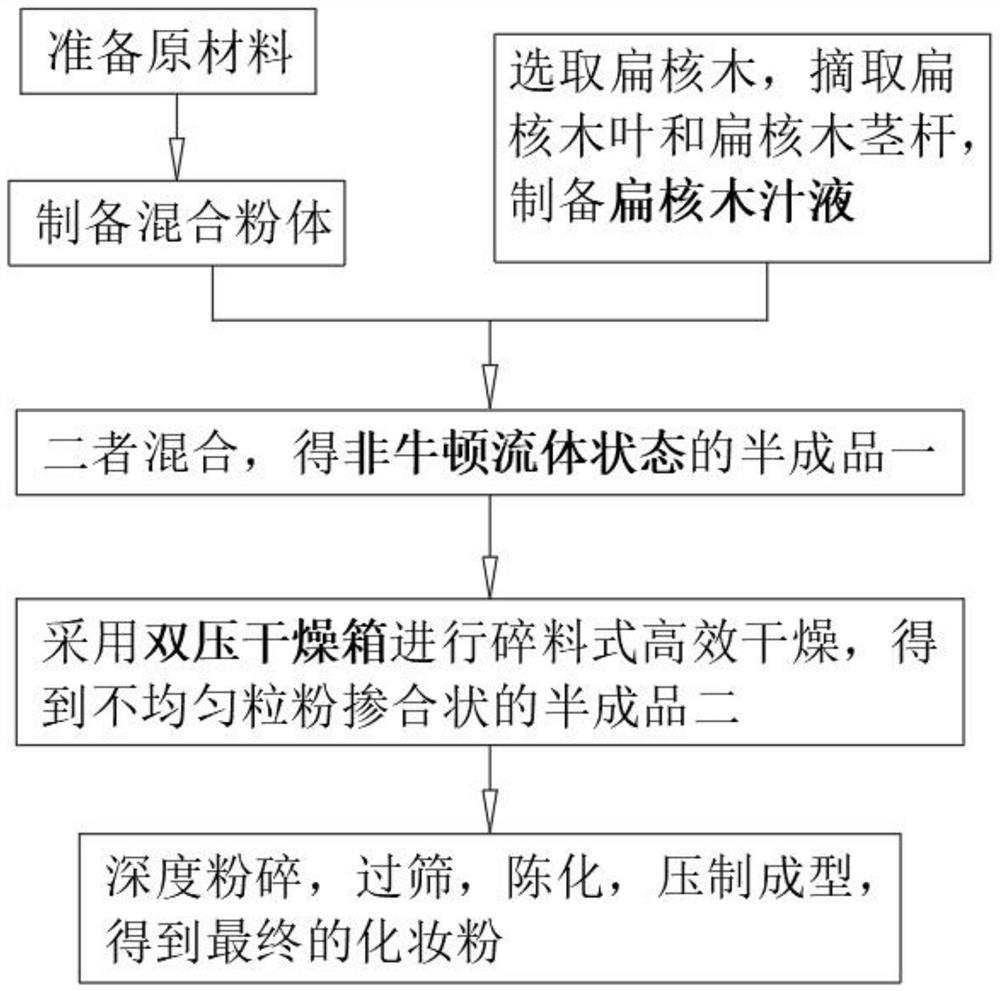

[0047] seefigure 1 , a kind of cosmetic powder preparation process containing flat core wood composition, comprises the following steps:

[0048] S1. Prepare various raw materials: matrix powder, pigment powder and regulator;

[0049] S2. Mix various matrix powders, then pulverize and sieve, then add pigment powder and regulator, pulverize and sieve again to obtain a mixed powder;

[0050] S3, choose the cypress in good growth condition, pick the cypress leaves with complete shape and the cypress stems less than 5mm in diameter, wash it with water, dry, mince then, add water to boil to extract the juice, filter, and then The juice is left to cool;

[0051] S4. Inject the flat wood juice obtained in step S3 into the mixed powder obtained in step S2, and the two are evenly mixed to form a semi-finished product 1 in a non-Newtonian fluid state;

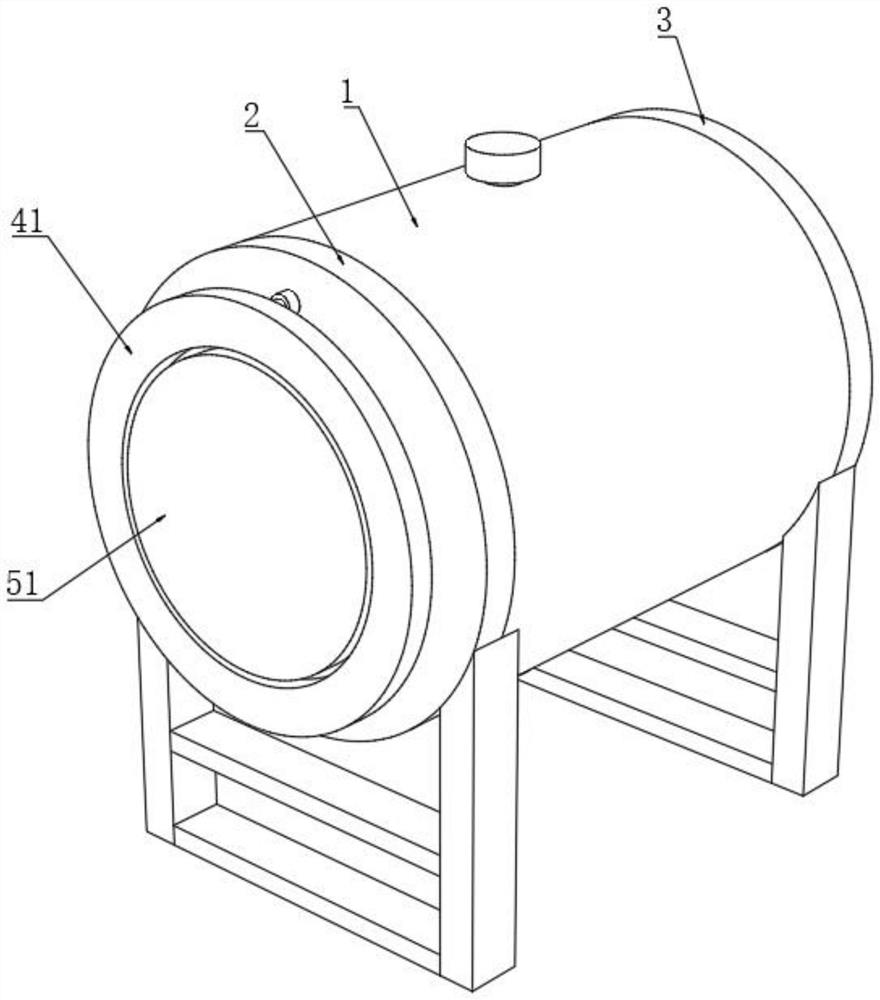

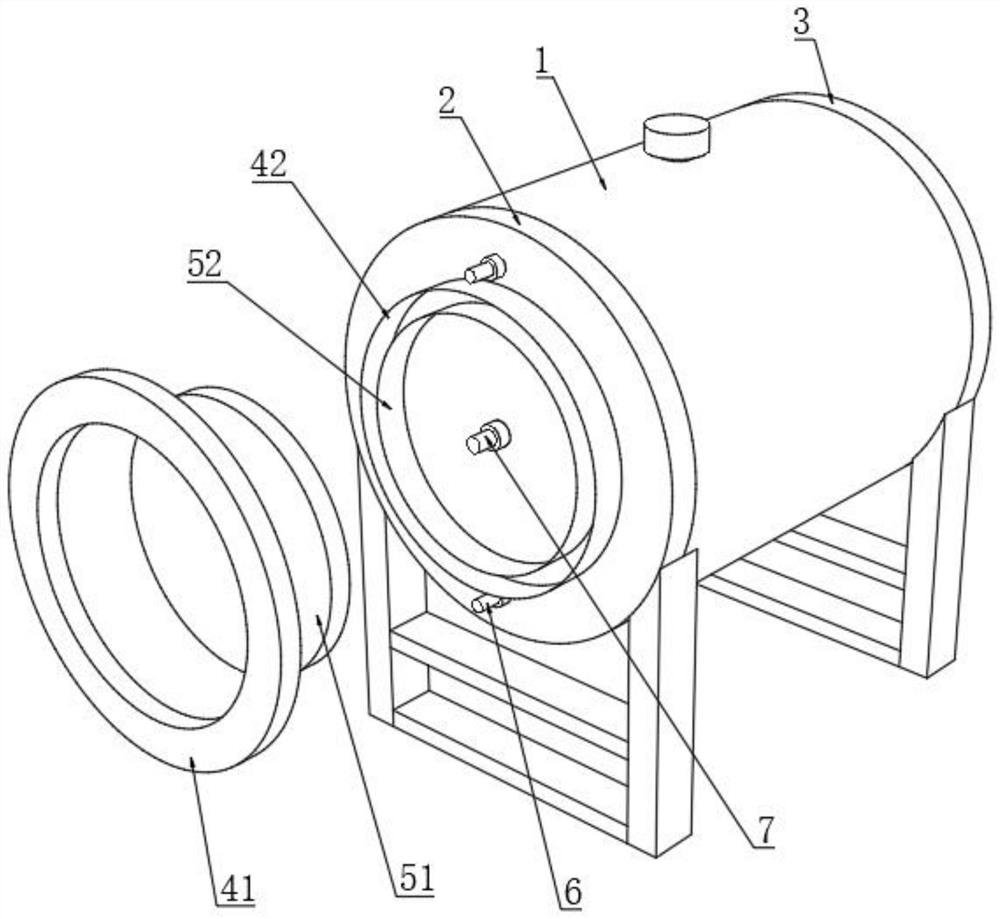

[0052] S5. Pass the semi-finished product 1 into a double-pressure drying box for high-efficiency drying of the crushed material, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com