High-selectivity reactor and method for preparing butanedioic anhydride through maleic anhydride liquid-phase hydrogenation

A maleic anhydride liquid-phase method and succinic anhydride technology, applied in chemical instruments and methods, organic chemistry, chemical/physical processes, etc., can solve the problem that succinic anhydride cannot take into account selectivity and large-scale industrial production, and achieve catalyst Small filling volume, avoiding hot spots, and improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

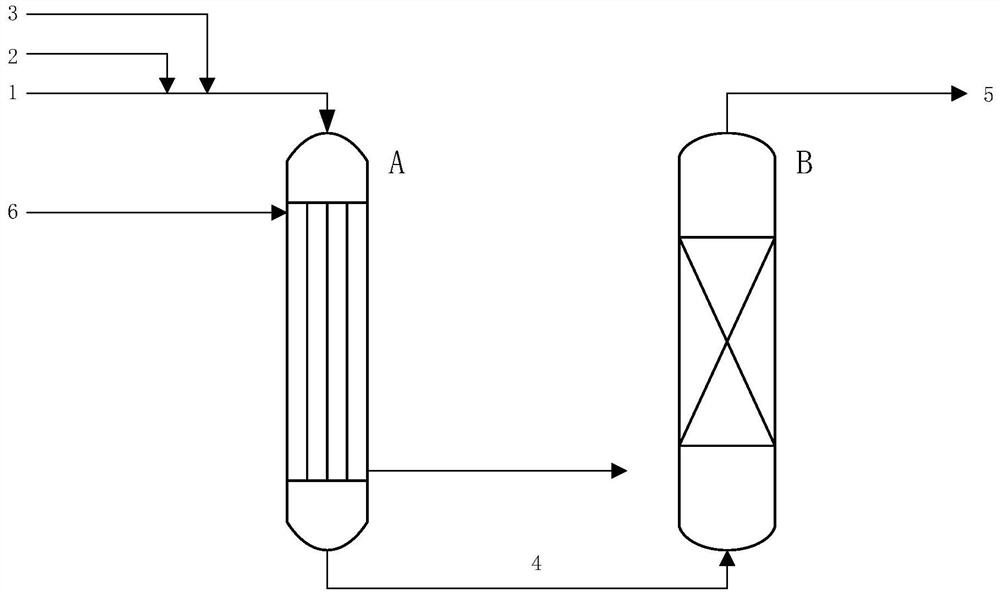

[0029] One non-adiabatic reactor A, in the specific form of a tubular fixed-bed reactor, and one adiabatic reactor B, in the specific form of a fixed-bed reactor. 5. 15t / h maleic anhydride 1 and γ-butyrolactone 2 are mixed at a volume ratio of 1:10, and hydrogen 3 (supplementary hydrogen + circulating hydrogen) is mixed at a volume ratio of 1:2, and enter the non-adiabatic Reactor A. The reaction materials enter the non-adiabatic reactor from top to bottom, the inlet temperature is 80°C, and the operating pressure of the reactor is 3.0MPa. The inner diameter of a single tube in the tube bundle in non-adiabatic reactor A is 190mm, and there are 420 row tubes, and the catalyst is filled in the tubes, and the volume space velocity is 0.5h -1 . The shell side is cooled by circulating water 7 at 30°C with a flow rate of 90.0t / h, which is operated in parallel with the reaction materials. The outlet temperature of the non-adiabatic reactor A is 95.0° C., and the maleic anhydride c...

Embodiment 2

[0031]Set up a non-adiabatic reactor A, the specific form is a tubular fixed-bed reactor, and an adiabatic reactor B, the specific form is a fixed-bed reactor. 5. 15t / h maleic anhydride 1 and γ-butyrolactone 2 are mixed at a volume ratio of 1:10, and hydrogen 3 (supplementary hydrogen + circulating hydrogen) is mixed at a volume ratio of 1:2, and enter the non-adiabatic Reactor A. The reaction materials enter the non-adiabatic reactor from top to bottom, the inlet temperature is 60°C, and the operating pressure of the reactor is 3.0MPa. In the non-adiabatic reactor A, the inner diameter of a single tube of the tube bundle is 190 mm, and there are 420 row tubes. The tubes are filled with catalyst, and the volume space velocity is 0.66 h-1. The shell side is cooled by circulating water 7 at 30°C with a flow rate of 90.0t / h, which is operated in parallel with the reaction materials. The outlet temperature of the non-adiabatic reactor A was 80.9° C., and the maleic anhydride con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com