Cleaning device for vibrating screen

A technology of cleaning device and vibrating screen, which is applied in the direction of filter screen, solid separation, chemical instruments and methods, etc., can solve the problems of cleaning device and screen surface cleaning adverse effects, etc., to reduce adverse effects, strong anti-fatigue ability, and improve cleaning efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

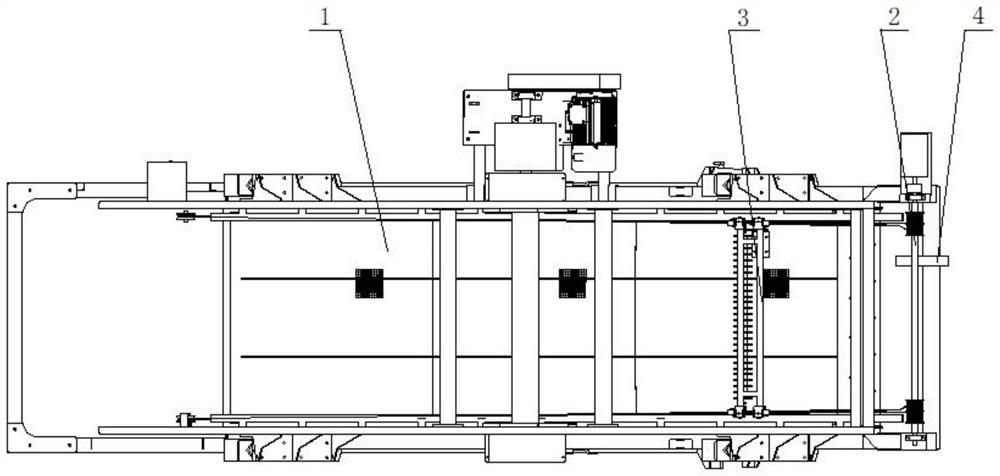

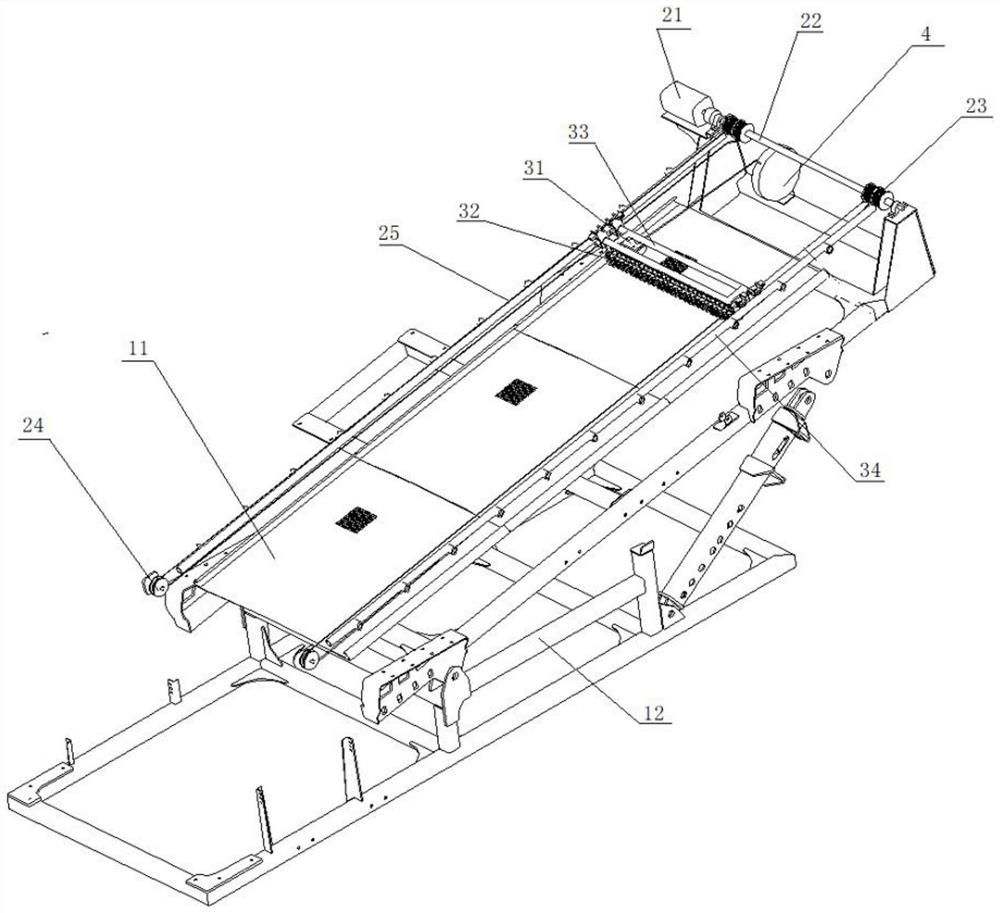

[0023] like figure 1 and figure 2 As shown, a cleaning device for a vibrating screen is used for cleaning the screen surface 11 of the vibrating screen 1. A frame 12 is arranged around the screen surface 11. When sugarcane is placed on the screen surface 11, the impurities in the sugarcane will be removed due to the The vibration of the sieve surface 11, and the sieve falls from the screen of the sieve surface 11.

[0024] The cleaning device includes a driving module 2 and a cleaning module 3, wherein:

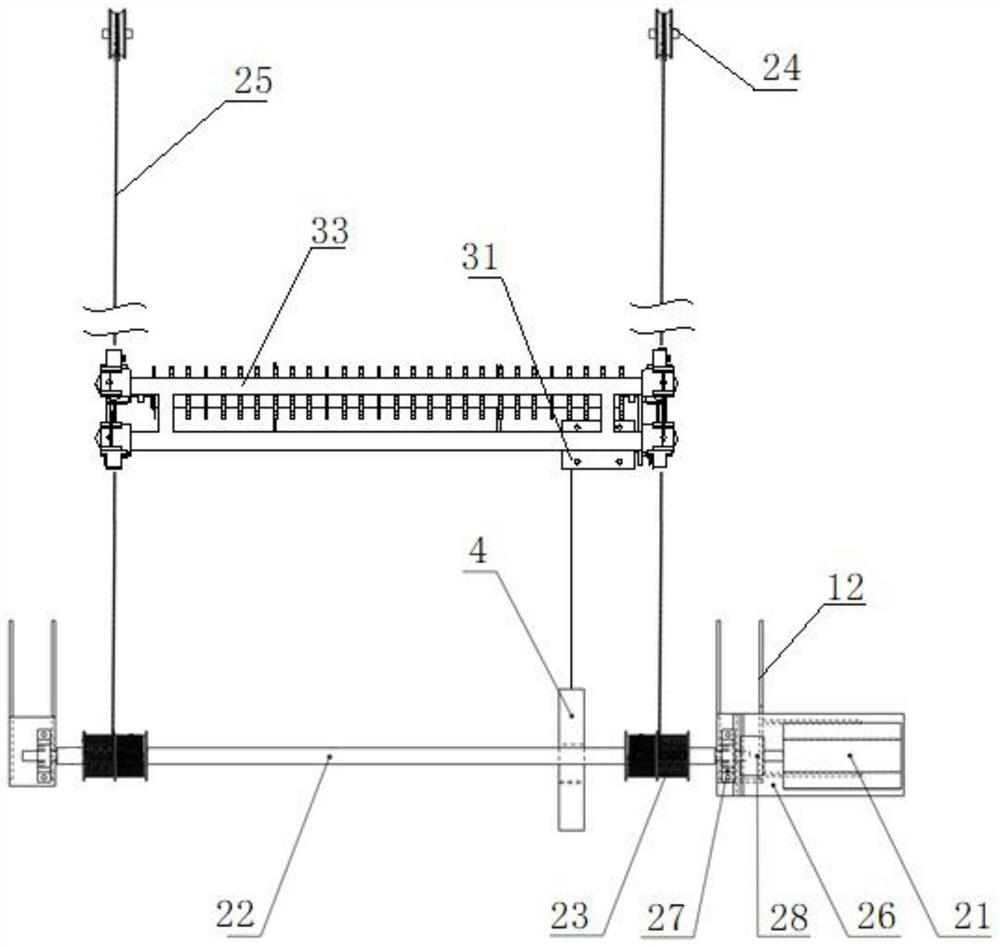

[0025] like image 3 As shown, the drive module 2 includes a first drive motor 21, a rotating shaft 22, a first roller 23, a second roller 24 and a wire rope ring 25, the first roller 23 is sleeved on the rotating shaft 22, and the rotating shaft 22 is arranged at the rear end of the screen surface 11, installed on the frame 12 through a bearing 27, and one end of the rotating shaft 22 is connected to the first driving motor 21 through a coupling 28 to realize the first d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com