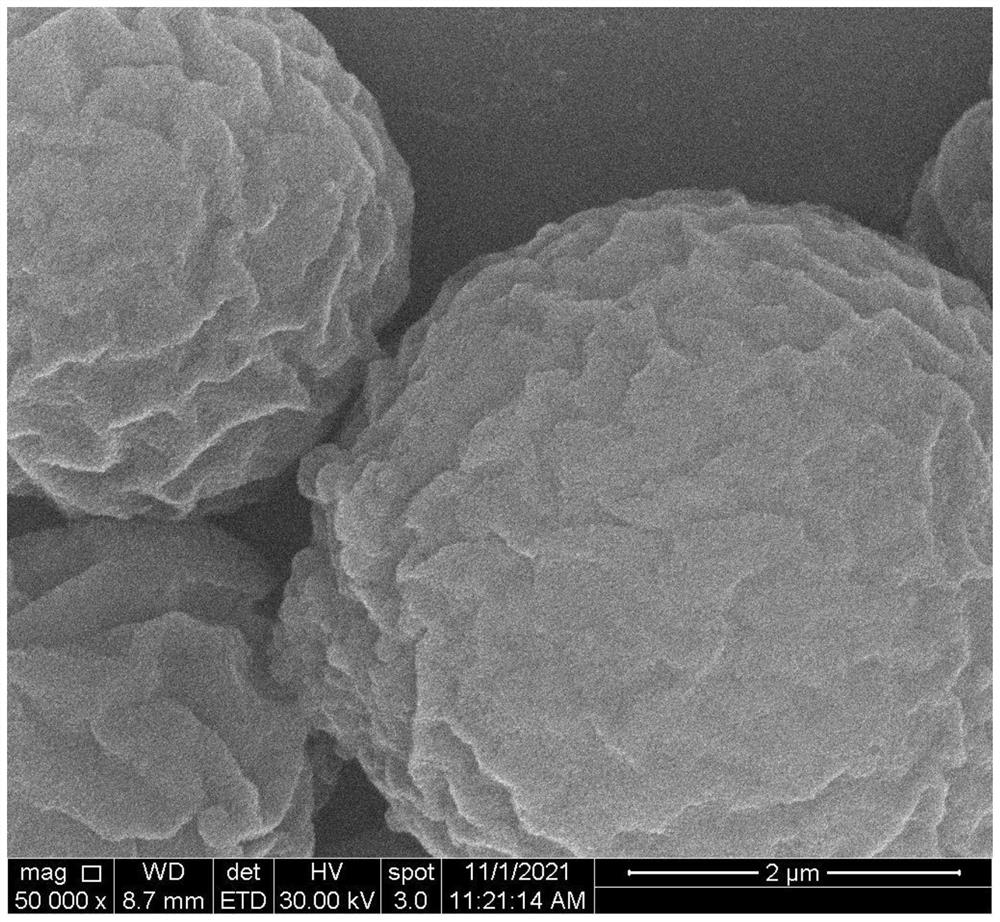

Polystyrene-SiO2 core-shell nano composite particle with wrinkled surface and preparation method of polystyrene-SiO2 core-shell nano composite particle

A technology of nanocomposite particles and polystyrene, which is applied in the field of polystyrene-SiO2 core-shell nanocomposite particles and its preparation, and can solve the problems that core-shell nanocomposite particles are rarely reported.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The present invention provides surface wrinkled polystyrene-SiO 2 Core-shell nanocomposite particles and a preparation method thereof, specifically comprising the following steps:

[0028] Step 1, on SiO 2 Emulsion polymerization of styrene in water in the presence of hydrosol, SiO 2 The hydrosol is commercially available glycerin functionalized SiO 2 Hydrosol and SiO 2 The weight ratio of hydrosol and styrene is 1:5, and the process of emulsion polymerization includes: first styrene, SiO 2 Add the hydrosol and water into a 100mL three-necked round-bottomed flask equipped with a condenser tube and a magnetic stirrer, pass nitrogen gas for 30 minutes, then continue to pass nitrogen gas and heat the oil bath to 60°C, then add 50 mg of azo to the first reaction vessel A solution of diisobutylamidine hydrochloride dissolved in 4g of water initiates polymerization, stir at 60°C and allow the reaction to continue for 24 hours. After the reaction is stopped, the reaction p...

Embodiment 3

[0049] This example provides surface wrinkled polystyrene-SiO 2 Core-shell nanocomposite particles and their preparation method are variations of Example 1. The variation is that in step 3, 150 mg of sodium lauryl sulfate is used to prepare toluene / water / sodium lauryl sulfate emulsion, specifically including The following steps:

[0050] Step 1, 5g styrene, 1.25g 40wt% SiO 2Add the hydrosol and 40.25g of water into a 100mL three-neck round-bottomed flask with a condenser tube and a magnetic stirrer, blow in nitrogen for 30 minutes, then continue to blow in nitrogen and heat the oil bath to 60°C, then inject 50mg of azobis A solution of isobutylamidine hydrochloride in 4 g of water was used to initiate polymerization, and the reaction was continued for 24 hours under stirring at 60° C., and the reaction product was obtained after stopping the reaction. The reaction product was centrifuged and washed 5 times (centrifugal speed 6000rpm, 30 minutes each time), and the supernatan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com