High-hardness thermoplastic polyurethane foaming coiled material and semi-continuous preparation method thereof

A thermoplastic polyurethane, high-hardness technology, applied in the field of new polyurethane, can solve the problems of difficult to effectively control the cell size, easy to escape, damage to the surface quality of the foamed material of the extruded foamed TPU material cell shape, etc., to achieve large-scale Continuous production, stable continuous temperature rise and foaming, the effect of suppressing the desorption phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

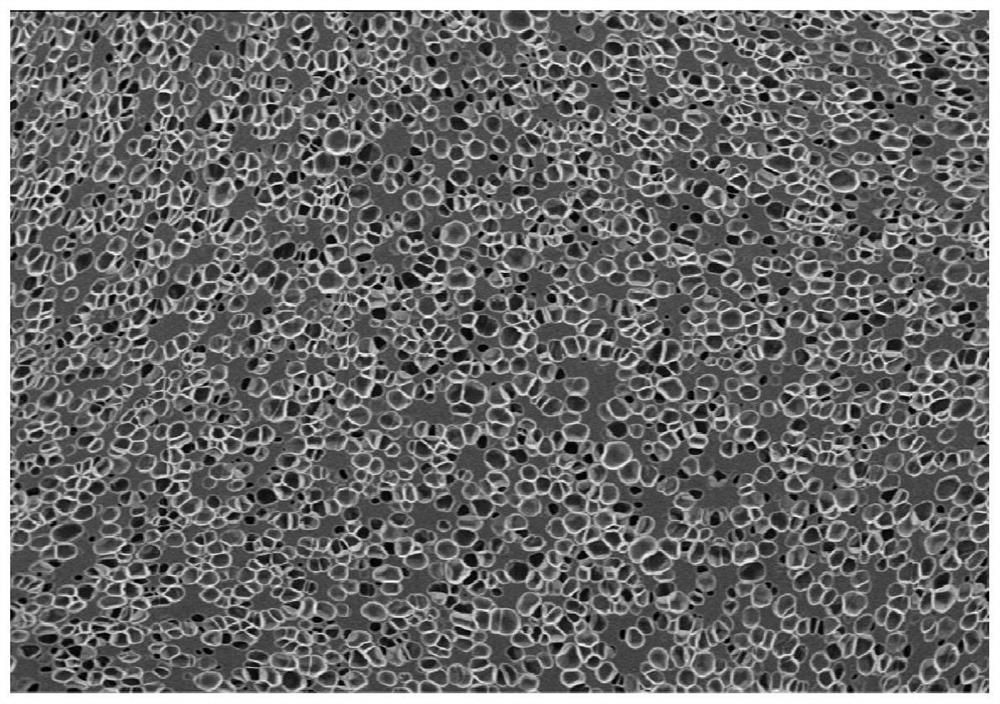

Image

Examples

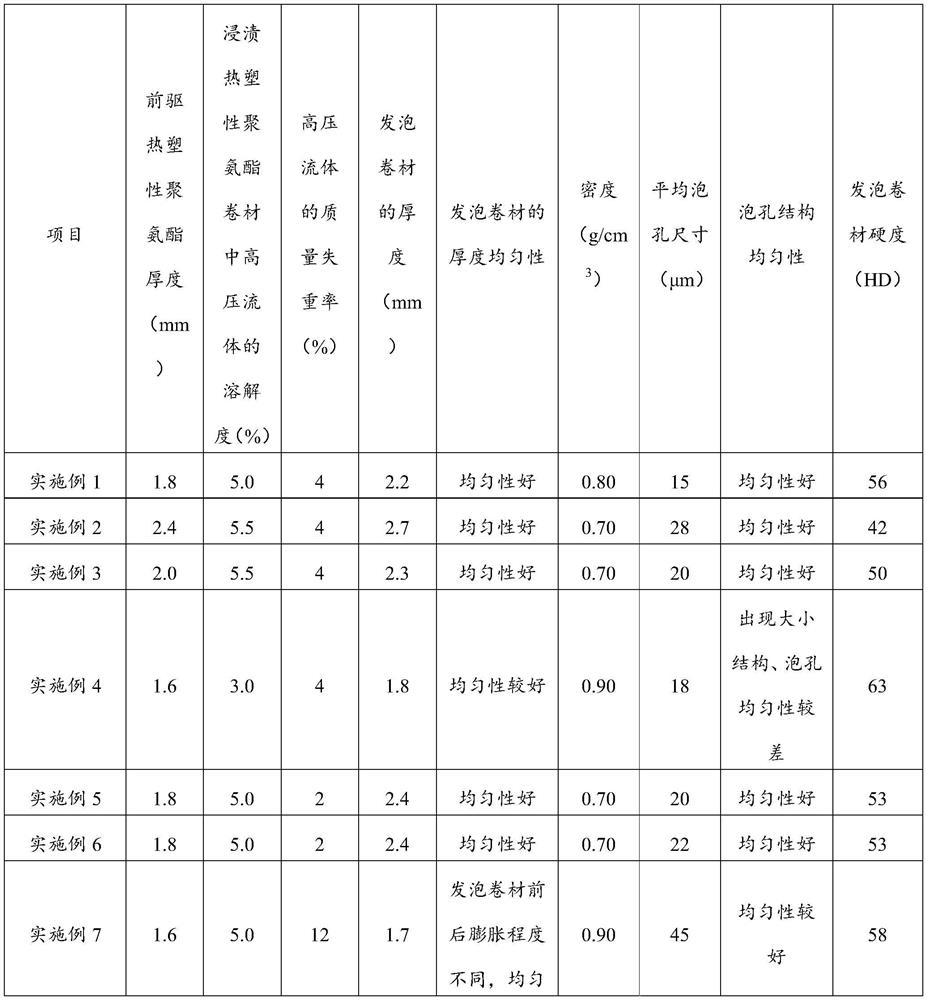

Embodiment 1

[0039] An embodiment of the high-hardness thermoplastic polyurethane foaming coil described in the present invention, the preparation method of the high-hardness thermoplastic polyurethane foaming coil described in this embodiment is as follows:

[0040] (1) After 100 parts of high-hardness thermoplastic polyurethane 1, 3 parts of lubricant and 0.3 part of antioxidant are sequentially dried, pre-mixed, twin-screw continuous extrusion, calendered and rolled, a precursor thermoplastic polyurethane roll with a thickness of 3mm is obtained material; the temperature of the extruder from the feeding port to the fourth temperature zone is set to 199°C, 204°C, 210°C, 215°C, and 216°C in sequence, and the temperature of the calender is controlled by 10°C circulating water, and the roller distance is 1.4mm. The temperature of the die head of the extruder is 213±0.2°C, and the temperature is controlled separately by heat conduction oil.

[0041] (2) Put the precursor thermoplastic polyur...

Embodiment 2~4

[0045] The embodiment of the high-hardness thermoplastic polyurethane foaming coil of the present invention, the difference between embodiment 2-4 and embodiment 1 is only that the high-hardness thermoplastic polyurethane used is different, respectively high-hardness thermoplastic polyurethane 2-4, the fourth The temperatures in the temperature zones are 215°C, 216°C, and 218°C, respectively, and the die head temperatures of the extruder are 213±0.2°C, 214±0.2°C, and 216±0.2°C, respectively, and the heat transfer oil is used to control the temperature separately.

Embodiment 5

[0047] The embodiment of the high-hardness thermoplastic polyurethane foam coil in the present invention, the difference between this embodiment and the embodiment 1 is that it is stored at a low temperature of -18° C. and then stored at a low temperature of 0° C. for 6 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com