Stabilization treatment method for iron-antimony waste residues

A technology for stabilization treatment and waste residue, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve problems such as thermodynamic instability, secondary pollution, poor stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

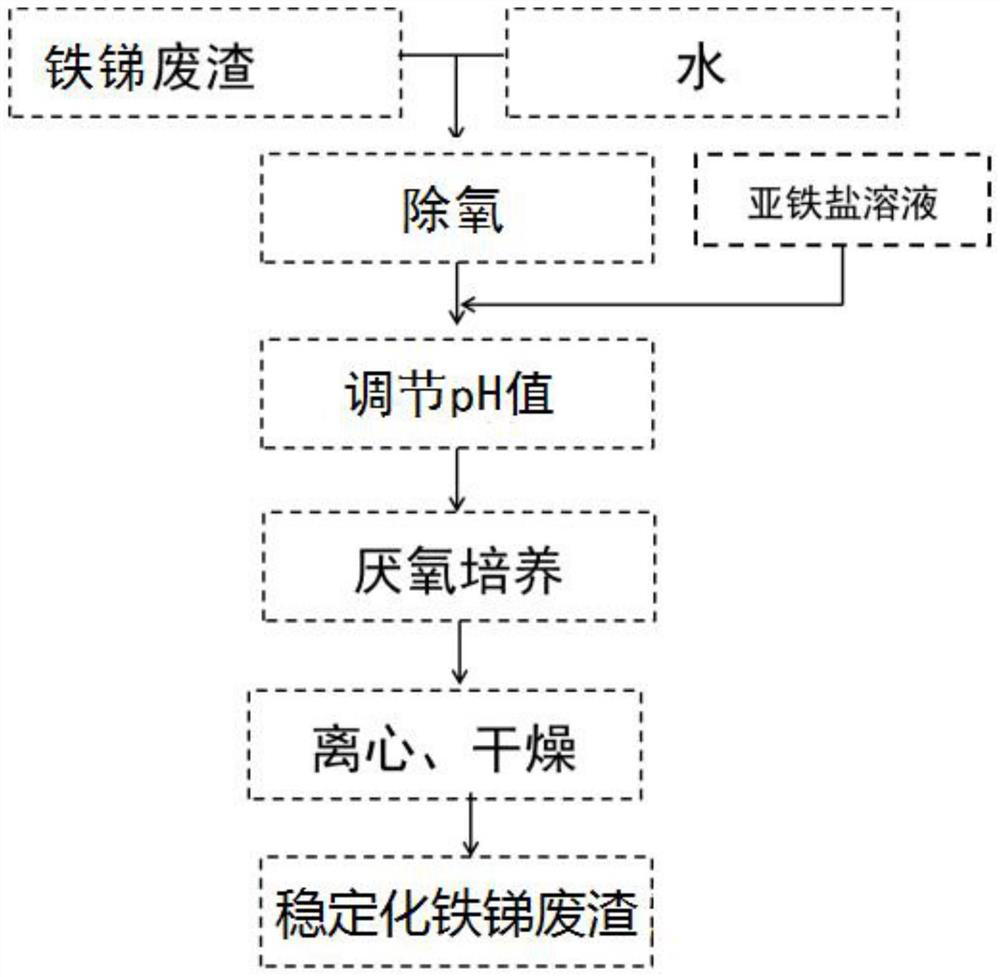

[0028] In the present invention, the preparation method of the simulated iron and antimony waste residue preferably includes the following steps:

[0029] The NaOH solution and the iron ion solution are mixed to obtain a turbid liquid; the turbid liquid is sequentially subjected to pH value adjustment, standing and filtration to obtain a filter cake; after mixing the filter cake, the sodium chloride solution and the antimony salt solution , centrifuged to obtain simulated iron-antimony waste residue.

[0030] In the present invention, the preparation method of the iron ion solution is preferably FeCl 3 ·4H 2 O is dissolved in water to obtain an iron ion solution. In the present invention, the water is preferably deionized water, and the FeCl 3 ·4H 2 The mass volume ratio of O and water is preferably (20 to 100) g:1L, and more preferably 54 g:1L.

[0031] In the present invention, the molar concentration of the NaOH solution is preferably 0.5-1.5 mol / L, more preferably 1 m...

Embodiment 1

[0048] 27g FeCl 3 ·4H 2 O and 500 mL of deionized water were stirred at room temperature for 10 min at 100 r / min to obtain an iron ion solution; 300 mL of 1 mol / L NaOH solution was poured into the iron ion solution, and then 30 mL of 1 mol / L NaOH solution was added at a rate of 50 drops / min The turbid solution was then added dropwise to the iron ion solution at a rate of 100 ppm to obtain a turbid solution; then the turbid solution was diluted to 1000 mL with deionized water, and the pH value of the diluted solution was adjusted with sodium hydroxide to 7.5, and then allowed to stand for 4 hours. , then carry out positive pressure filtration at a pressure of 0.15Mpa, and wash with deionized water 3 times during the filtration process to obtain a filter cake; after mixing 4g of filter cake and 990mL of anaerobic water, add 10mL of 0.5mol / L sodium chloride solution , and passed nitrogen at a rate of 150mL / min for 12h aeration; the aerated product and sodium pyroantimonate solut...

Embodiment 2

[0051] The difference with Example 1 is that in the process of preparing the simulated iron-antimony waste residue, the mol ratio of trivalent iron and pentavalent antimony in the vibration product is 50:1, the content of antimony in the simulated iron-antimony waste residue is 6000 mg / kg, and the remaining contents Consistent with Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com