Chemical chain gasification reaction device and method thereof

A technology of gasification reaction and gasification reactor, which is applied in the field of chemical chain gasification reaction device, can solve problems such as difficult to eradicate tar escape, increase fluidization wind speed, increase fan energy consumption, etc., and achieve extensive social benefits and industrial prospects , increase productivity, and save fan energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

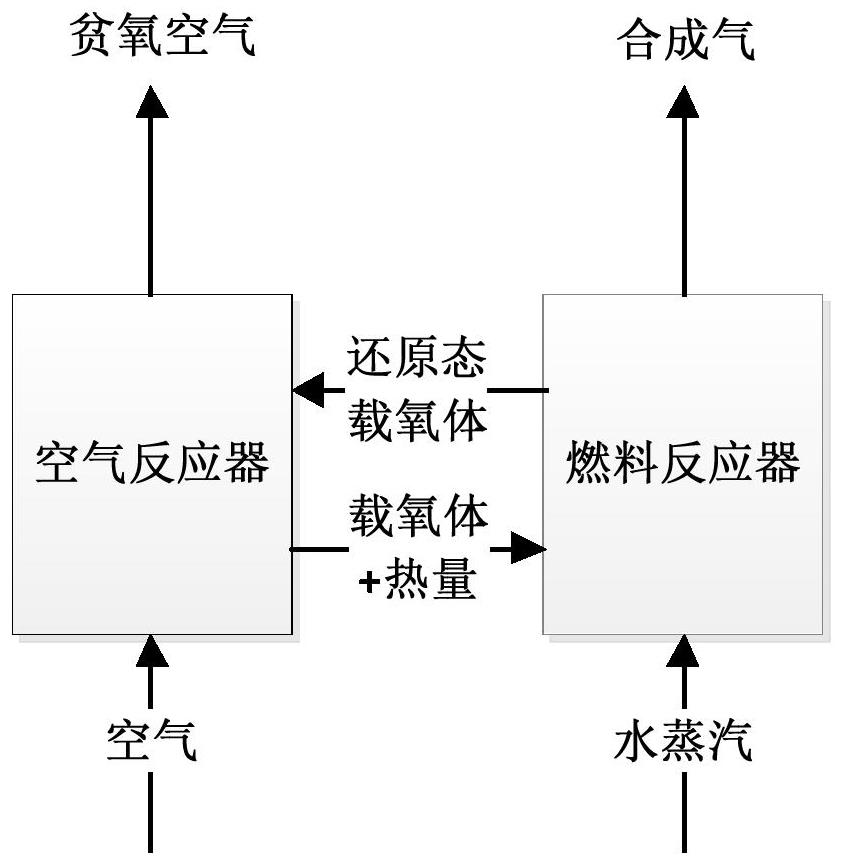

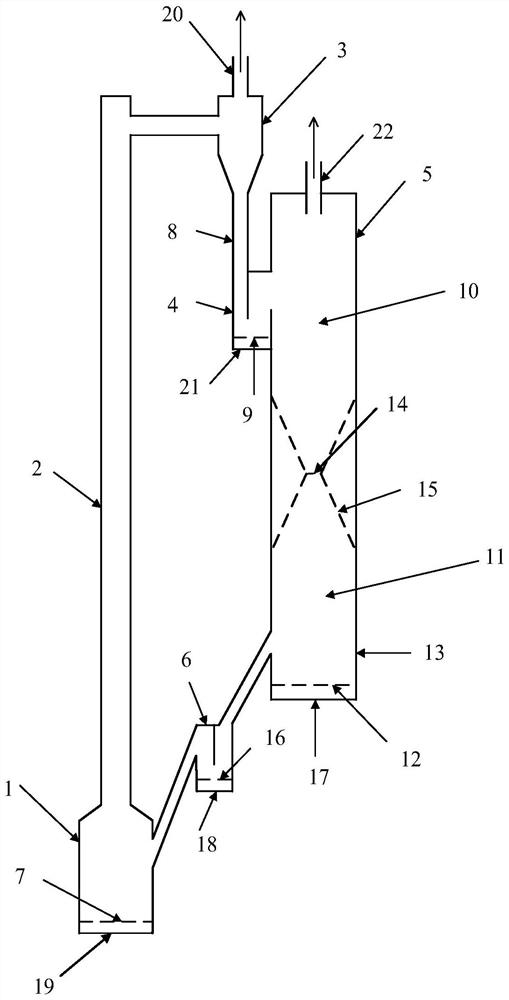

[0044] Such as figure 2 As shown, the main body of the reaction device is composed of an air reactor 1, a riser 2, a cyclone separator 3, an air reactor returner 4, a fuel reactor 5 and a fuel reactor returner 6 to form a circulating gasification reaction device. Air reactor 1 bottom is provided with air inlet 19, and air reactor air distribution plate 7 is arranged on the top of air reactor 1 bottom and air inlet 19, and the middle part of air reactor 1 side is provided with feed inlet, and air reactor The upper part of 1 is connected with the riser 2 through a pipeline, the riser 2 is connected with the cyclone separator 3 through a pipeline, the top of the cyclone 3 is provided with an oxygen-poor air outlet 20, and the upper end of the discharge pipe 8 is discharged from the bottom of the cyclone 3 The lower end of the discharge pipe 8 is connected to the top of the air reactor feeder 4, and the air reactor feeder 4 side is provided with a return port in the middle, and t...

Embodiment 2

[0048] (1) Before passing into the fluidization gas, the fuel is piled up at the bottom of the gasification reactor 11, and the oxygen carrier is initially piled up at the bottom of the gasification reactor 11, the bottom of the air reactor 1, the bottom of the air reactor feeder 4 and the bottom of the air reactor 11 respectively At the bottom of the feeder 6 of the fuel reactor, the conversion of fuel to high-grade synthesis gas is realized through the circulation of oxygen carrier particles in the device.

[0049] (2) The fuel enters the bottom of the gasification reactor 11, and the reaction temperature is 700°C to 1000°C. The gasification reactor 11 is a bubbling fluidized bed with a dense phase zone and a dilute phase zone, and the fuel enters the bottom of the gasification reactor 11. In the dense phase zone, the gasification medium is passed into the first gasification medium inlet 17, and the synthesis gas produced by the gasification of the fuel under the catalytic co...

Embodiment 3

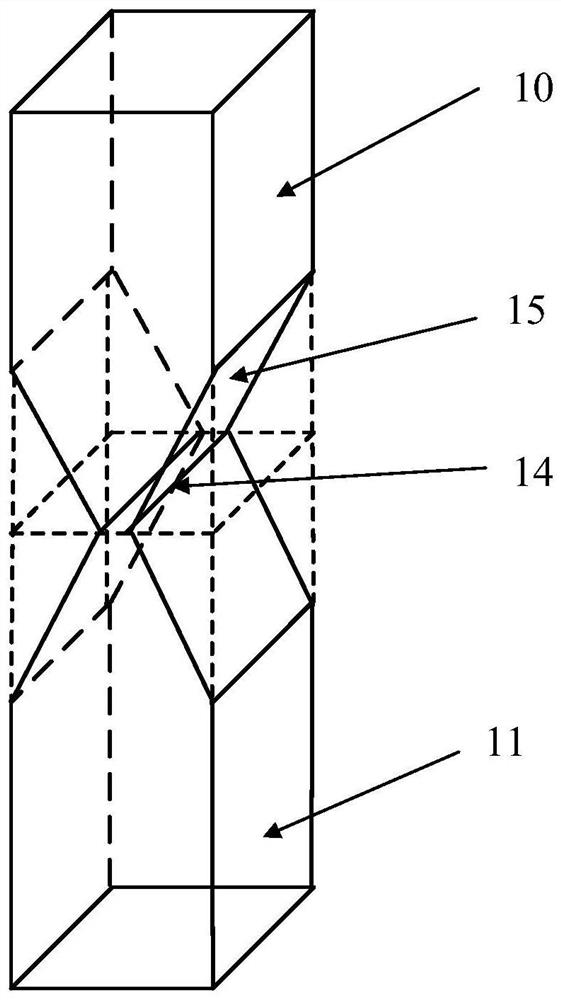

[0056] The present invention builds the fuel reactor 5 of cold staged fluidization, adopts particle diameter to be 0.6mm, bulk density is 1700kg / m 3 Quartz sand particles are used as the experimental material, the superficial gas velocity is in the range of 0.1-0.7m / s in the experimental working condition, and 8 pressure measuring points (P1-P8) are arranged. Such as Figure 6 As shown, it can be clearly observed that under the appropriate material accumulation height and superficial gas velocity, bubbling fluidization appears in the gasification reactor, and the reforming reactor presents jet fluidization; at the same time, the reforming reaction Particles in the reactor gradually fall into the gasification reactor, forming the communication of the particles inside the fuel reactor.

[0057] At the same time, compared with the conventional air distribution plate connection method, the gasification reactor and the reforming reactor adopted in the present invention are connect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com