Rescreening and recycling system for noil waste

A recovery system and waste cotton technology, applied in the field of spinning, can solve the problems of low spinning yield, achieve the effect of ensuring the speed, increasing the yield, and ensuring the loosening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

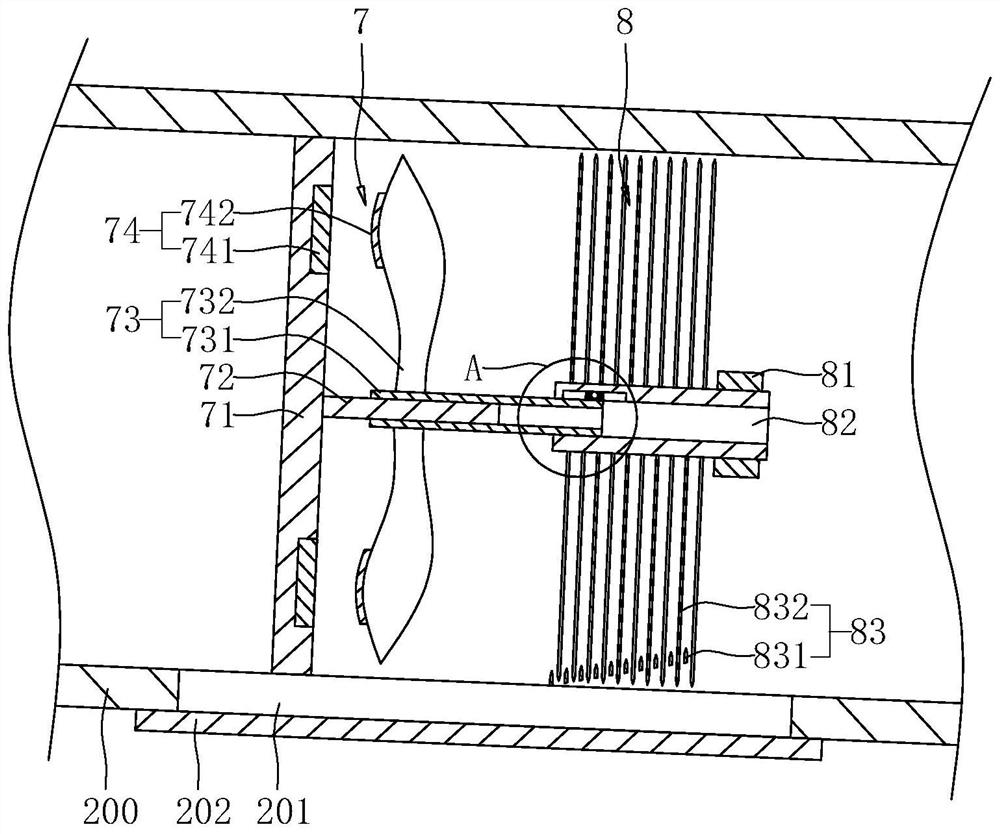

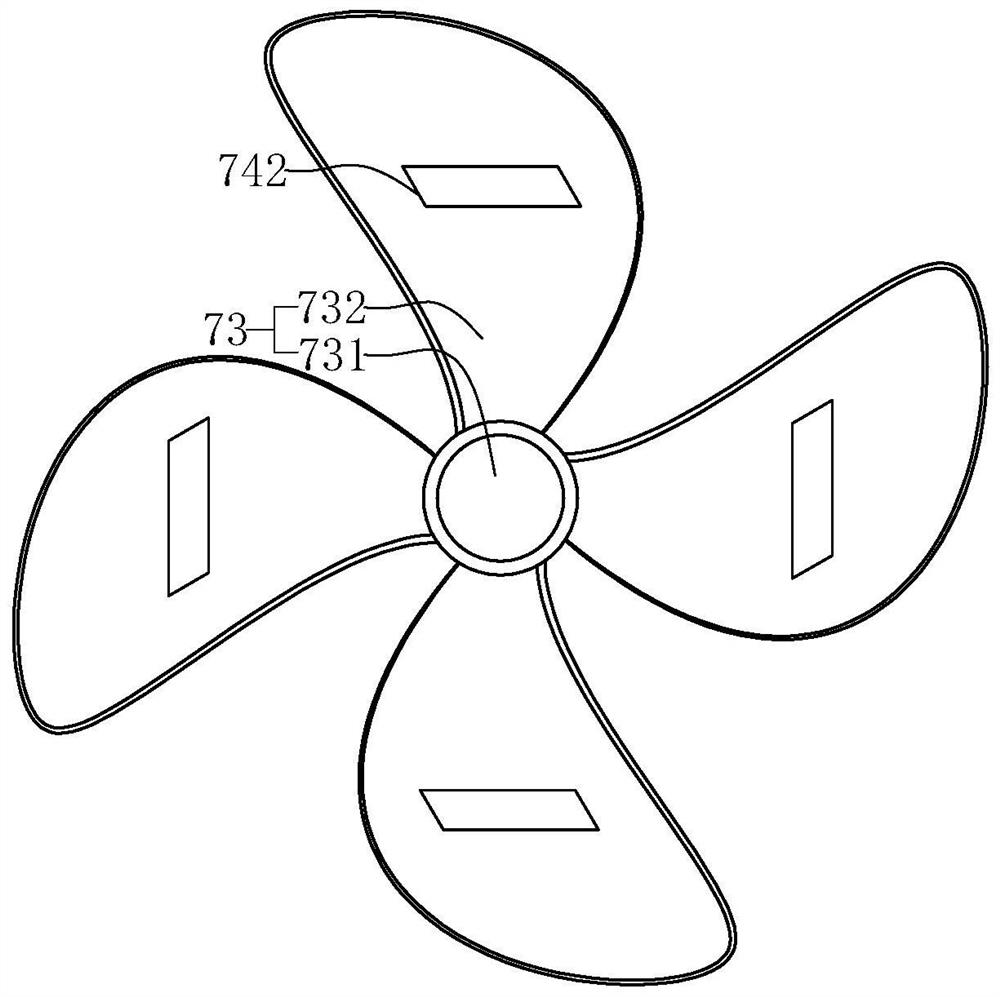

[0031] The following is attached Figure 1-4 The application is described in further detail.

[0032] The embodiment of the present application discloses a noil waste re-screening and recovery system.

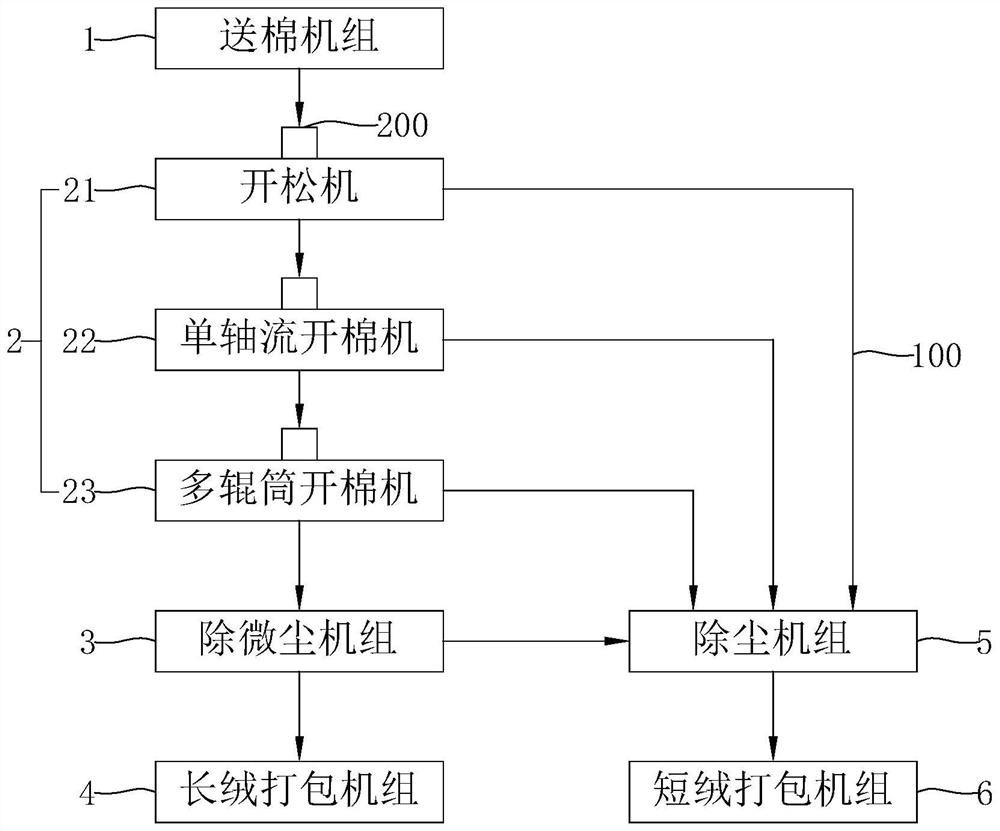

[0033] refer to figure 1 , the noil waste re-screening and recycling system includes a cotton feeding unit 1, a cotton opening unit 2, a dust removal unit 3, a long-staple baler unit 4, a dust removal unit 5, and a short-staple baler unit 6; Machine 21, single axial flow opener 22 and multi-roller opener 23.

[0034]Specifically, in this embodiment, the cotton feeding unit 1 adopts an automatic cotton feeding machine, and the cotton feeding unit 1 can initially disperse and transport waste cotton. What the opener 21 adopts is an automatic opener, and the opener 21 can open the noil, and preliminarily screen out some short-staple cotton dust impurities, and the screened short-staple cotton dust impurities are processed by the opener 21. The short-staple cotton dust impuritie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com