Cutting abrasion test bed frame

An abrasion test and frame technology, applied in the field of basic frame, can solve the problems of unsatisfactory test effect, large test bench, and high development cost, and achieve the effect of compact test bench structure, flexible placement, and reduced test cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

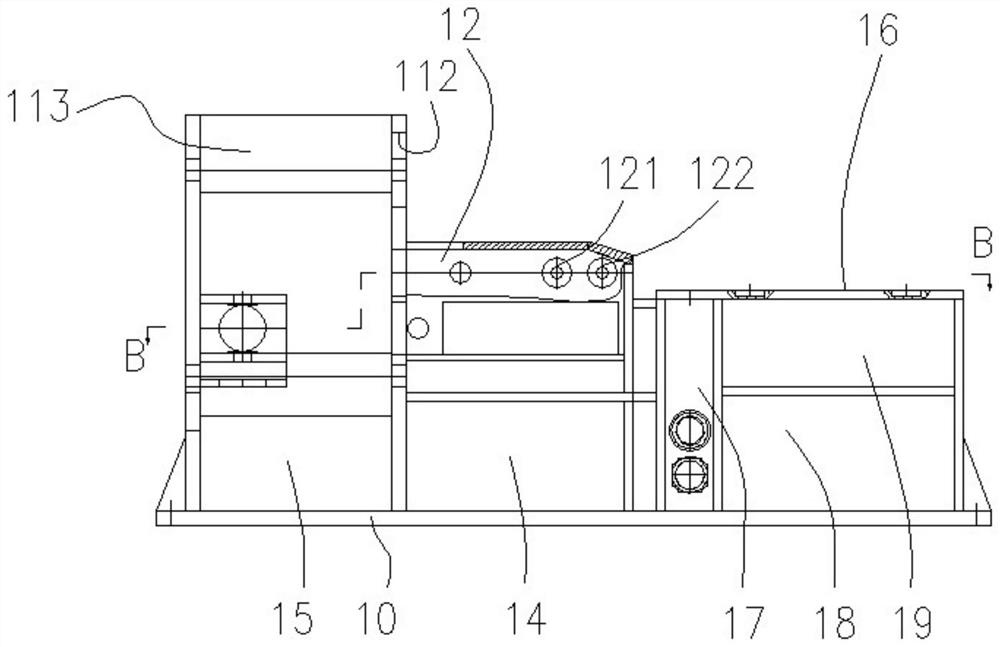

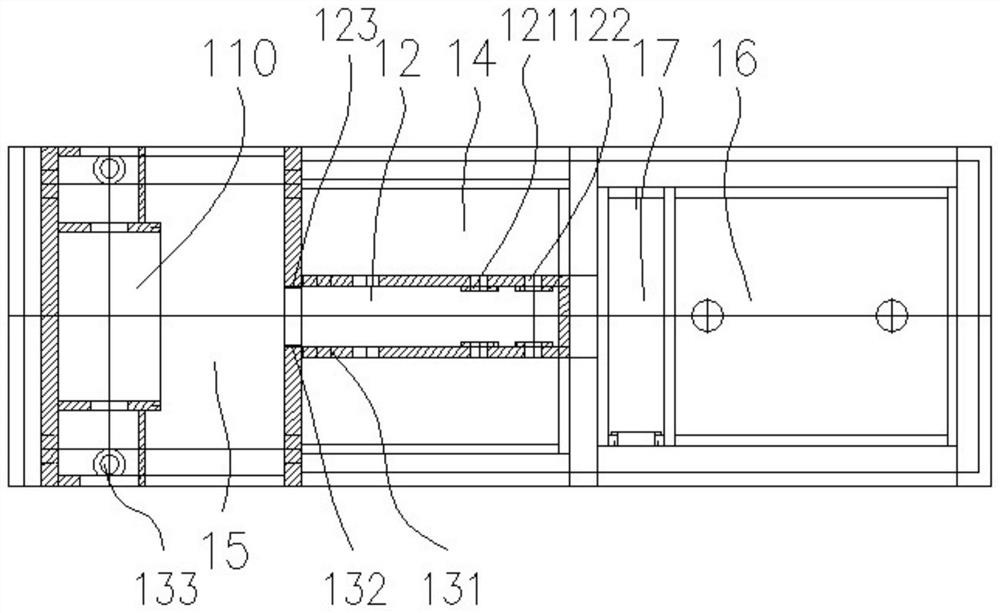

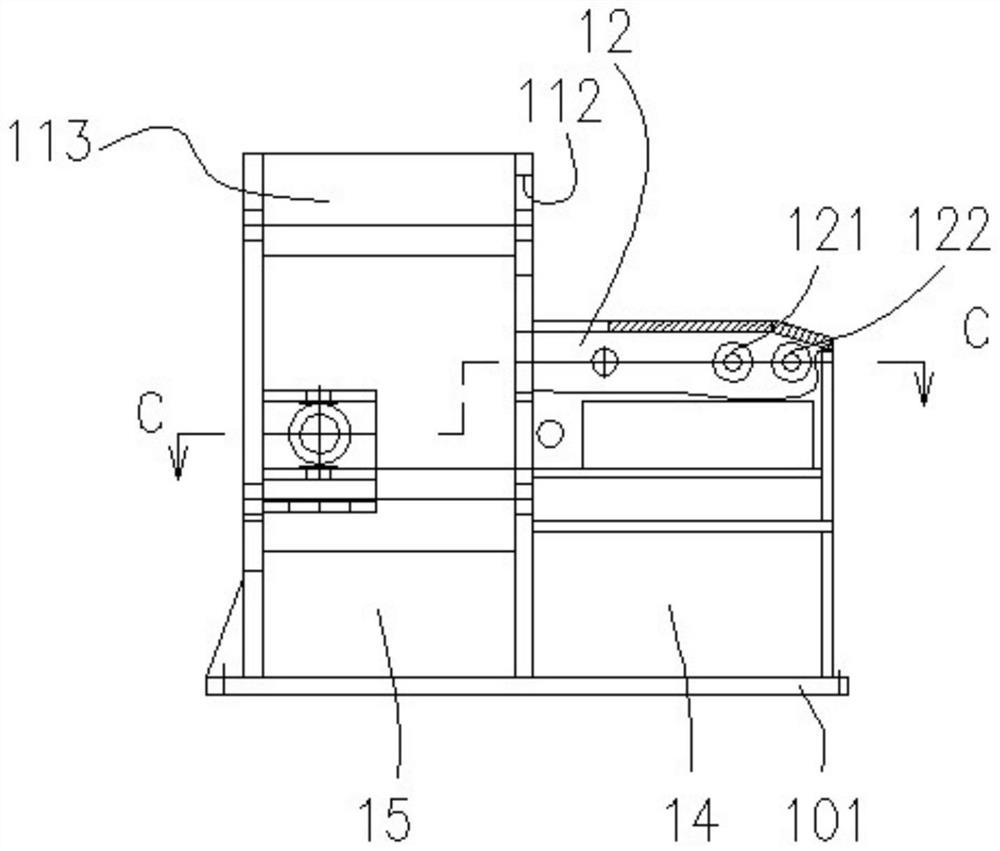

[0034] Such as Figure 1-9 As shown, the present invention discloses a cutting and abrasion test bench frame 1 (which may be referred to as a frame for short), and the frame is a basic structure for installing other equipment and components on the cutting and abrasion test bench. The frame is formed by tailor welding of multiple plates. The frame is divided into a front area, a middle area and a rear area from front to back. The front area is sequentially provided with a cut rock sample placement cavity and a cut debris collection cavity 15 from top to bottom. The cut rock sample placement cavity is the main area where the cutting head 26 moves back and forth to cut the cut rock sample 01 during the cutting test. Collect cuttings.

[0035] The central area is provided with an oil cylinder installation chamber 12, a manual control chamber and an active power system installation chamber 14 sequentially from top to bottom, wherein the oil cylinder installation chamber is in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com