Aircraft landing gear cabin flow oscillation control method

A landing gear cabin and control method technology, applied in aircraft parts, computer-aided design, computer material science, etc., can solve problems such as failure to respond to dynamic characteristics, damage to aerodynamic performance, and change of configuration, so as to improve the flow environment in the cavity, Effect of suppressing noise level and reducing pressure oscillations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

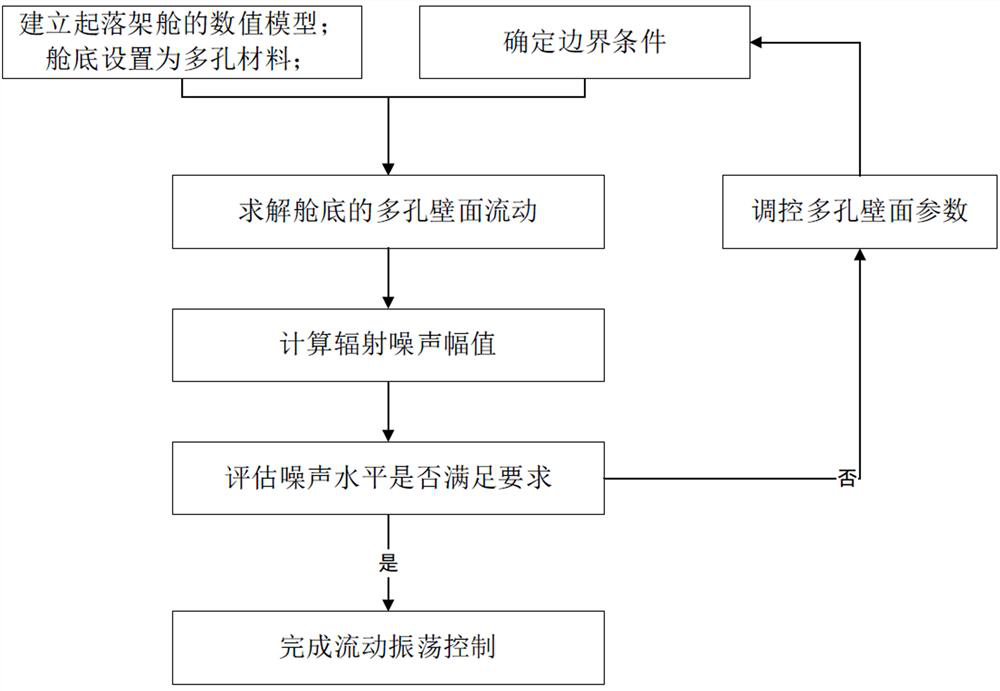

[0062] Such as figure 1 A method for controlling the flow oscillation of an aviation aircraft landing gear compartment includes the following steps:

[0063] A numerical model of the landing gear compartment is established, in which the bottom of the landing gear compartment is set as a porous material;

[0064] determine the boundary conditions;

[0065] Substituting the boundary conditions into the numerical model to solve the porous wall flow of the bilge;

[0066] Calculate the radiated noise amplitude based on the flow data on the porous wall of the bilge;

[0067] Estimate the noise level and adjust the porous wall parameters based on the noise level:

[0068] If the noise level in the main radiation direction meets the set requirements, the control process ends;

[0069] If the noise level in the main radiation direction does not meet the set requirements, maintain the porosity of the porous material β No change, adjust back pressure p , re-solve the porous wall ...

Embodiment 2

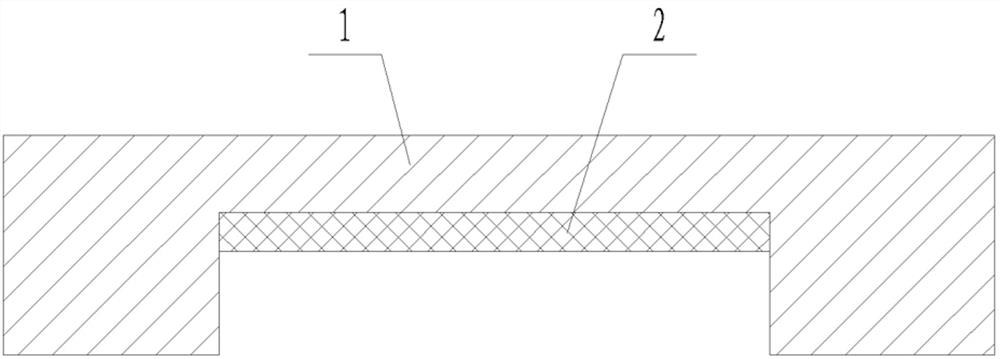

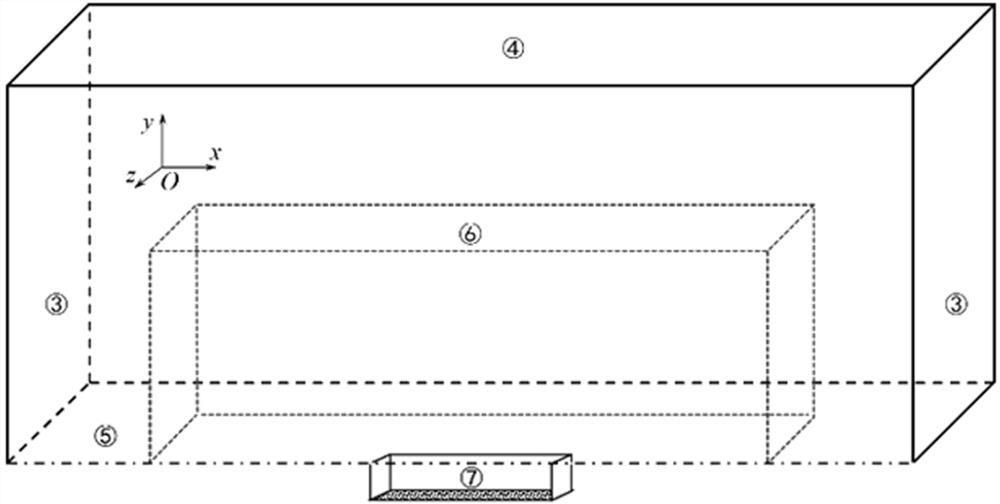

[0072] A method for controlling the flow oscillation of an aircraft landing gear compartment. In this embodiment, a typical M219 type landing gear compartment is used as the research object. The landing gear compartment and the corresponding aircraft such as figure 2 and image 3 shown. In the configuration of the landing gear compartment, the length: width: depth is 5:1:1. When Mach number Ma=0.85, Reynolds number Re=0.6×10 7 When flowing through this configuration, a typical self-sustained oscillation occurs.

[0073] This embodiment will first image 3 The configuration of the landing gear compartment is modeled in Figure 4 The model shown in . During the modeling process, the undercarriage with the downward opening is symmetrically changed to the upward opening with respect to the horizontal plane, and the following is obtained: Figure 4 For the model shown, this setup eases modeling without changing the flow characteristics.

[0074] Then determine the boundary ...

Embodiment 3

[0097] A flow oscillation control system for an aircraft landing gear compartment, based on the oscillation control method of any of the above embodiments, comprising:

[0098] The modeling module is used for establishing the numerical model of the landing gear compartment, and setting the bilge of the landing gear compartment as a porous material in the numerical model;

[0099] Boundary module for determining boundary conditions;

[0100] Calculation module, used to calculate the porous wall flow of the bilge and the corresponding radiation noise amplitude;

[0101] A control module is used to regulate the porous wall parameters according to the noise level.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com