Preparation method and device of cast ingot for high-toughness and high-corrosion-resistance aluminum alloy thick plate

An aluminum alloy, high corrosion resistance technology, applied in the field of aluminum alloy casting, can solve the problems of insufficient measurement accuracy and product quality, waste of manpower, material and financial resources, falling off, etc., to improve the casting success rate and product quality, and improve the finished product. rate and yield, and the effect of avoiding potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A preferred embodiment of the present invention provides a method for preparing an ingot for a high-toughness and high-corrosion-resistant aluminum alloy thick plate, as well as the supporting equipment for preparing an ingot for a high-toughness and high-corrosion-resistant aluminum alloy thick plate. The goal is to prepare a 450mm* Ingots for Al-Zn-Mg-Cu high-toughness and high-corrosion-resistant aluminum alloy thick plates with specifications of 1800mm*6500mm.

[0036] Among them, the Al-Zn-Mg-Cu aluminum alloy is formulated according to the following mass percentages: Si=0.023%, Fe=0.031%, Zn=7.7~8.2%, Mg=1.6~1.9%, Cu=1.7~2.1%, Mn=0.003%, Cr=0.002%, Ti=0.03%, Zr=0.11%, each inevitable impurity element is less than 0.03%, and the total amount is less than 0.1%, and the balance is Al.

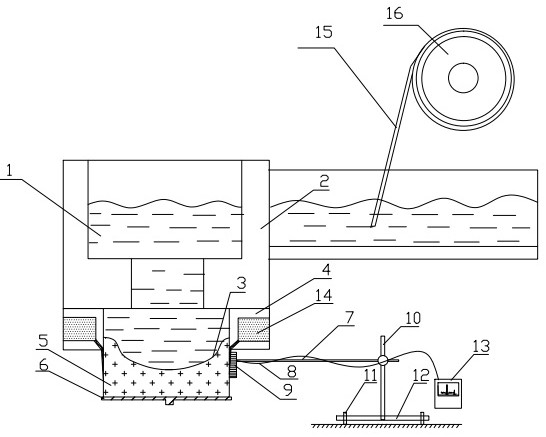

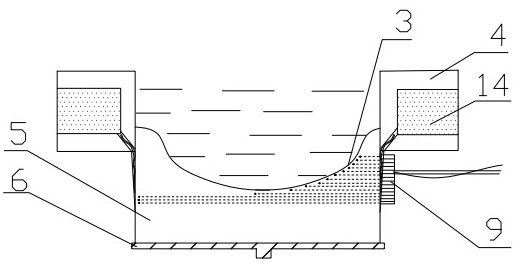

[0037] Please refer to figure 1 , the equipment for preparing ingots for high-toughness and high-corrosion-resistant aluminum alloy thick plates includes launder 2, casting mold 4, d...

Embodiment 2

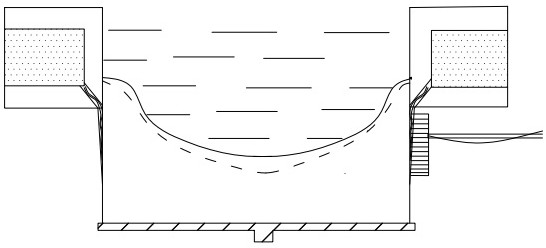

[0047] This preferred embodiment provides a method for preparing an ingot for a high-toughness and high-corrosion-resistant aluminum alloy thick plate, as well as the supporting equipment for preparing an ingot for a high-toughness and high-corrosion-resistant aluminum alloy thick plate, and the prepared ingot specifications and The chemical composition is the same as that of Example 1. The difference from Example 1 is that in this preferred embodiment, the ultrasonic probe set 9 uses a multi-channel single crystal probe set and a supporting multi-channel ultrasonic instrument to measure the casting liquid cavity. Ultrasonic probe group 9 uses 20 single-crystal probes with a diameter of 25.4 mm and a center frequency of 2.5 MHz. Multiple single-crystal probes are staggered in two columns to achieve effective sound beam coverage. Different probes measure different depths of liquid cavities, such as Figure 4 As shown, specifically, each channel excites the single-crystal probe i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com