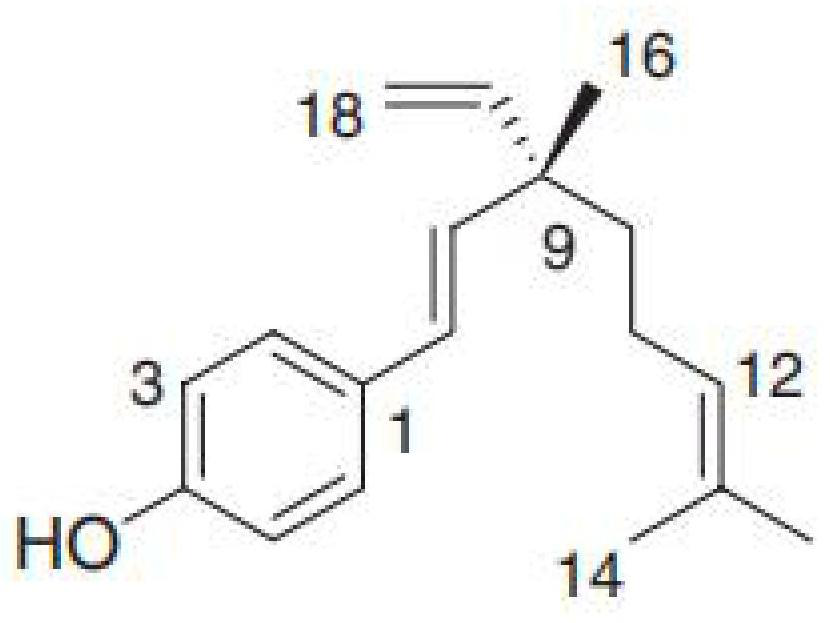

Method for extracting bakuchiol from elm roots and purifying bakuchiol and application of bakuchiol in cosmetics

A technology of bakuchiol and cosmetics, which is applied in the direction of cosmetics, cosmetic preparations, chemical instruments and methods, and can solve problems such as inflammation, skin sensitivity, and allergies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

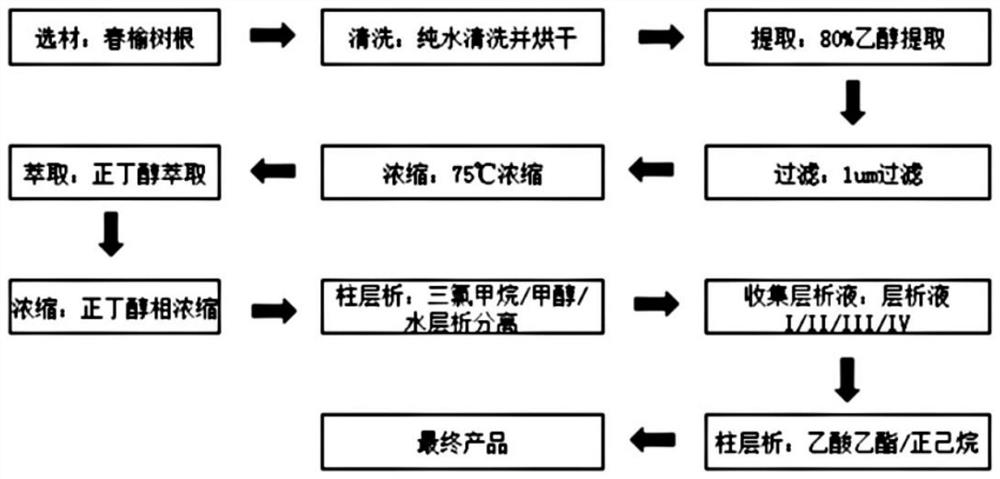

Method used

Image

Examples

Embodiment 1

[0028] 001, select the spring elm root raw material, clean it with pure water, dry it, and crush it for later use;

[0029] 002, the crushed spring elm root was extracted with 5 times 80% ethanol at 70°C for 4 hours, cooled to room temperature, filtered with 1um filter paper, and the filtrate was collected.

[0030] 003, concentrate the leach filtrate under reduced pressure at 75°C to 1 / 7 of the filtrate, recover ethanol at the same time, and collect the concentrated residue;

[0031] 004, extract the concentrated residue with 1.5 times of n-butanol, collect the n-butanol part, and concentrate under reduced pressure at 60°C until there is no n-butanol;

[0032] 005, the n-butanol fraction residue was separated by silica gel column chromatography, and the fraction residue was separated into four subgroups I, II, III, and IV using a development system of chloroform / methanol / water=6:4:1 Minute;

[0033] 006, using a mixture of ethyl acetate: hexane at a ratio of 1:2 as the elue...

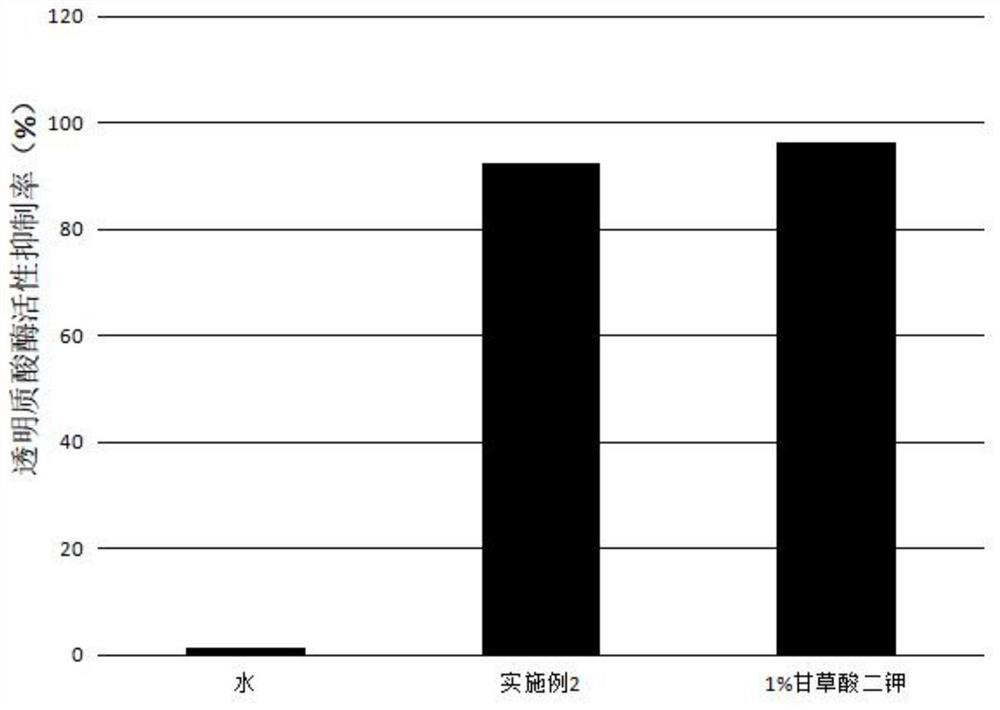

Embodiment 2

[0035] 001, select the spring elm root raw material, clean it with pure water, dry it, and crush it for later use;

[0036] 002, the crushed spring elm root was extracted with 3 times 70% ethanol at 60°C for 6 hours, cooled to room temperature, filtered with 1um filter paper, and the filtrate was collected.

[0037] 003, concentrating the leach filtrate under reduced pressure at 75°C to 1 / 10 of the filtrate, while recovering ethanol, and collecting the concentrated residue;

[0038] 004, extract the concentrated residue with 2 times of n-butanol, collect the n-butanol part, and concentrate under reduced pressure at 65°C until there is no n-butanol;

[0039] 005, the n-butanol fraction residue was separated by silica gel column chromatography, and the fraction residue was separated into four subgroups I, II, III, and IV by using a development system of chloroform / methanol / water=5.5:4.5:1 Minute;

[0040] 006, using a mixture of ethyl acetate: hexane at a ratio of 1:1.5 as the...

Embodiment 3

[0042] 001, select the spring elm root raw material, clean it with pure water, dry it, and crush it for later use;

[0043] 002, the crushed spring elm root was soaked and extracted with 3 times 60% ethanol at 75°C for 3 hours. After the extraction was completed, the temperature was cooled to room temperature, filtered with 1um filter paper, and the filtrate was collected.

[0044] 003, concentrating the leach filtrate under reduced pressure at 75°C to 1 / 10 of the filtrate, while recovering ethanol, and collecting the concentrated residue;

[0045] 004, extract the concentrated residue with 2 times of n-butanol, collect the n-butanol part, and concentrate under reduced pressure at 65°C until there is no n-butanol;

[0046] 005, the n-butanol fraction residue was separated by silica gel column chromatography, and the fraction residue was separated into four subgroups I, II, III, and IV by using a developing system of chloroform / methanol / water=5.5:5:1 Minute;

[0047] 006, usi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com