Low-heat-generation and tear-resistant rubber composition for engineering tire and preparation method of low-heat-generation and tear-resistant rubber composition

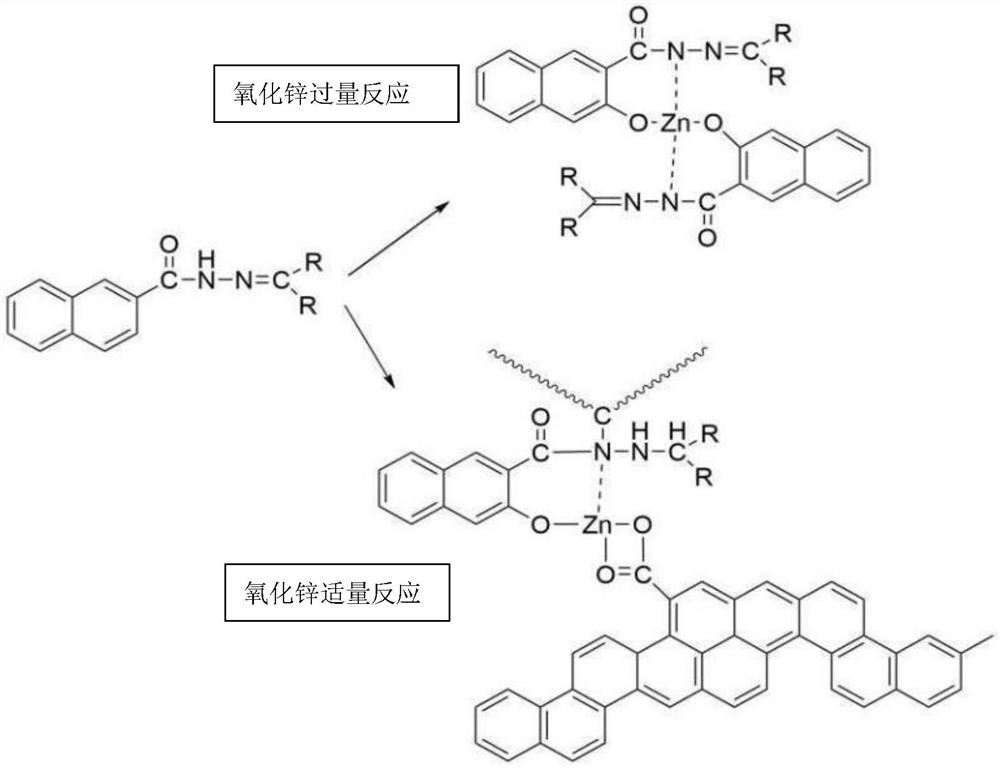

A rubber composition and tear-resistant technology, which is applied in the field of rubber compositions, can solve the problems of high heat generation performance and poor tear resistance performance of tires, and achieve improved tear strength, improved tear resistance performance, and improved TKPH value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Add 100 parts of natural rubber SMR20, 30 parts of N330 carbon black, 1 part of zinc oxide, 2 parts of stearic acid, 0.8 parts of rubber modifier DC-01, and 1 part of EN-01 into the internal mixer for mixing into a piece of masterbatch;

[0034] (2) Mix a section of masterbatch, 15 parts of white carbon black, 1.5 parts of silane coupling agent TESPT, 1 part of antiaging agent RD, and 1 part of antiaging agent 4020 into a second section of masterbatch; according to the Mooney viscosity and process requirements of the masterbatch, It can continue to be re-refined to make three-stage and four-stage masterbatches;

[0035] (3) Put the above-mentioned masterbatch mixture on hold for 8 hours, then add 3 parts of zinc oxide, 0.5 parts of accelerator NS, 0.5 parts of accelerator CZ, 0.3 parts of accelerator DM, and 1.8 parts of sulfur in the internal mixer and mix , After the mixed rubber was parked for 8 hours, it was vulcanized to positive vulcanization with a flat vulc...

Embodiment 2

[0037] (1) Add 100 parts of polyisoprene rubber STR20, 30 parts of N330 carbon black, 1 part of zinc oxide, 2 parts of stearic acid, 0.8 parts of rubber modifier DC-01, and 1 part of EN-01 into the banburying Mixing in the machine to form a section of masterbatch;

[0038](2) Mix a section of masterbatch, 15 parts of white carbon black, 1.5 parts of silane coupling agent γ-mercaptopropyl-trimethoxysilane, and 1 part of antioxidant 4020 into a second section of masterbatch; according to the Mooney viscosity of the masterbatch and According to the technical requirements, it can continue to remelt to make three-stage and four-stage masterbatch;

[0039] (3) Put the above-mentioned masterbatch mixture on hold for 8 hours, then add 3 parts of zinc oxide, 0.5 parts of accelerator NS, 0.5 parts of accelerator CZ, 0.3 parts of accelerator DM, and 1.8 parts of sulfur in the internal mixer and mix , After the mixed rubber was parked for 8 hours, it was vulcanized to positive vulcanizat...

Embodiment 3

[0041] (1) Add 100 parts of styrene-butadiene rubber SBR1502, 25 parts of N375 carbon black, 2 parts of zinc oxide, 0.5 part of stearic acid, add 0.1 part of rubber modifier DC-01, and 1 part of EN-01 into the internal mixer for mixing refining into a section of masterbatch;

[0042] (2) Mix a section of masterbatch, 1 part of white carbon black, 0.1 part of silane coupling agent bis(triethoxypropylsilane) tetrasulfide and disulfide, and 0.5 part of antioxidant RD to form a second section of masterbatch;

[0043] (3) After parking the above masterbatch compound for 8 hours, add 1 part of zinc oxide, 0.5 part of accelerator NS, and 0.5 part of insoluble sulfur in the internal mixer and then mix it. After parking the compound rubber for 8 hours, vulcanize it with a flat plate After being vulcanized to normal vulcanization at 150°C, the rubber composition was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com