Sidewall rubber material as well as preparation method and application thereof

A sidewall rubber and rubber technology, which is applied in the field of sidewall rubber and its preparation, can solve problems such as limited mileage, and achieve the effects of improved mileage, high modulus, and excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

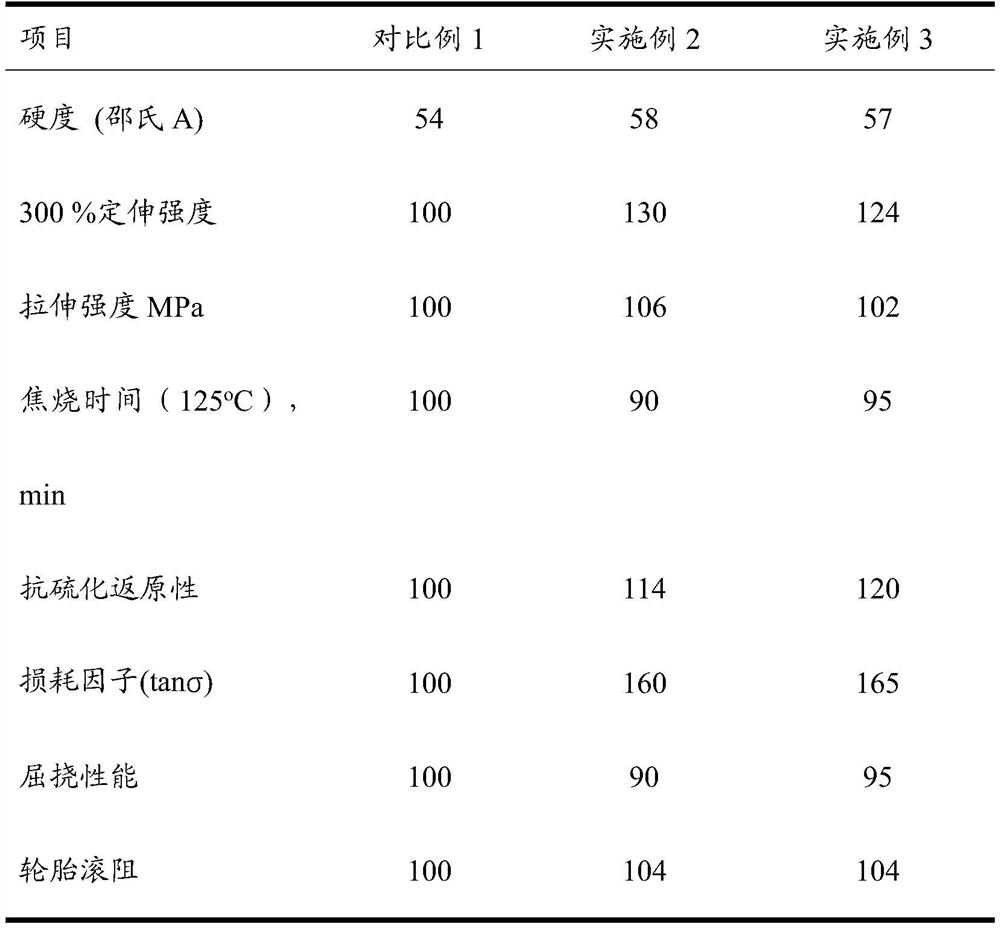

Examples

Embodiment 1

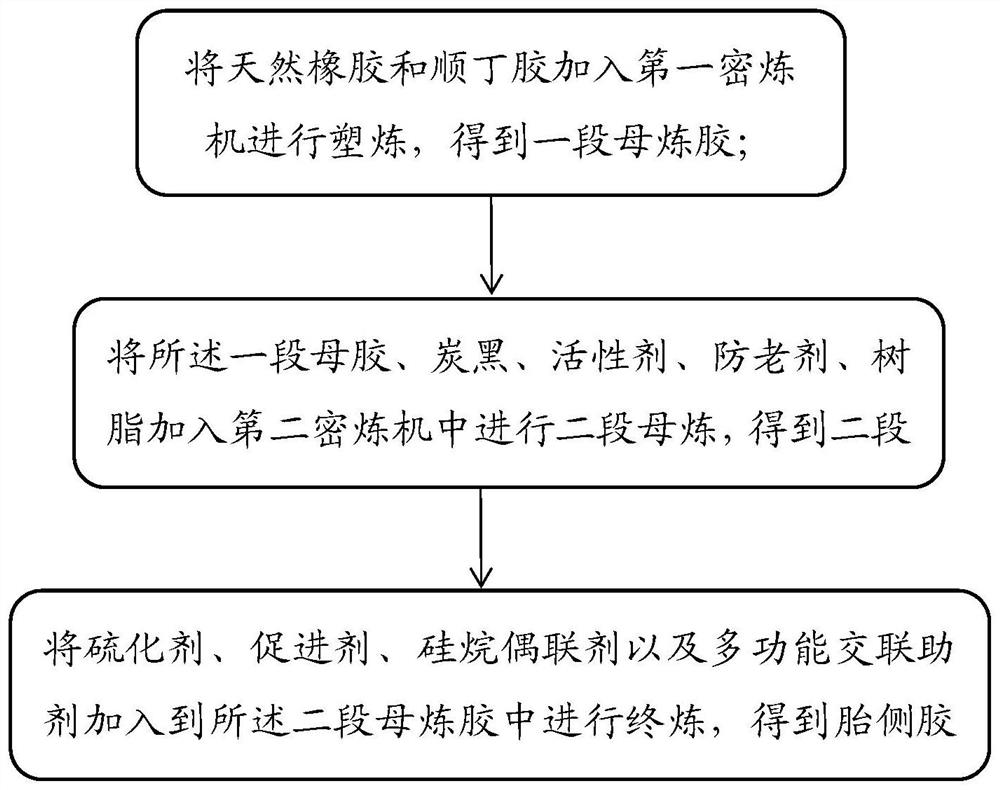

[0068] The present embodiment 1 provides the preparation method of the first tire sidewall compound, comprising the following steps:

[0069] Step 1, adding natural rubber and modified butadiene rubber into an internal mixer for masticating to obtain a section of masterbatch;

[0070] Step 2, a section of masterbatch prepared in step 1, with a specific surface area of 35m 2 N660 carbon black, active agent, anti-aging agent, and tackifying resin of / g are added to the internal mixer to carry out the second-stage masterbatch to obtain the second-stage masterbatch;

[0071] Step 3, adding insoluble sulfur IS7020, ordinary sulfur, and accelerator NS to the second-stage masterbatch prepared in step 2, and performing final refining to obtain tire sidewall rubber;

[0072] Among them, in step 1, the mixing time of the first master batch is 110-150s, and the debinding temperature is preferably 160°C; in step 2, the time of the second master batch is 130s-160s, and the debinding tem...

Embodiment 2

[0075] The present embodiment 2 provides the preparation method of the second tire sidewall compound, comprising the following steps:

[0076] Step 1, adding natural rubber and modified butadiene rubber into an internal mixer for masticating to obtain a section of masterbatch;

[0077] Step 2, a section of masterbatch prepared in step 1, with a specific surface area of 35m 2 N660 carbon black, active agent, anti-aging agent, and tackifying resin of / g are added to the internal mixer to carry out the second-stage masterbatch to obtain the second-stage masterbatch;

[0078] Step 3, adding insoluble sulfur IS7020, common sulfur, accelerator NS and silane coupling agent Si69 and 1,6 bis(N,N dibenzylthiocarbamoyl disulfide) alkane to the two-stage mother prepared in step 2 In rubber mixing, final refining is carried out to obtain tire sidewall rubber;

[0079] Among them, in step 1, the mixing time of the first master batch is 110-150s, and the debinding temperature is preferab...

Embodiment 3

[0082] Present embodiment 3 provides the preparation method of the 3rd kind of tire sidewall compound, comprises the following steps:

[0083] Step 1, adding natural rubber and modified butadiene rubber into an internal mixer for masticating to obtain a section of masterbatch;

[0084] Step 2, a section of masterbatch prepared in step 1, with a specific surface area of 35m 2 N660 carbon black, active agent, anti-aging agent, and tackifying resin of / g are added to the internal mixer to carry out the second-stage masterbatch to obtain the second-stage masterbatch;

[0085] Step 3, adding insoluble sulfur IS7020, common sulfur, accelerator NS and silane coupling agent Si69 and 1,6 bis(N,N dibenzylthiocarbamoyl disulfide) alkane to the two-stage mother prepared in step 2 In rubber mixing, final refining is carried out to obtain tire sidewall rubber;

[0086] Among them, in step 1, the mixing time of the first master batch is 110-150s, and the debinding temperature is preferab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com