Water-resistant fireproof thermal insulation coating for building external wall and production process of water-resistant fireproof thermal insulation coating

A technology for fire protection and heat preservation and building exterior walls, which is applied in the direction of fire protection coatings, anti-corrosion coatings, reflection/signal coatings, etc. It can solve the problems of aging and falling off, less coating functions, etc., achieve strong viscosity, avoid coating thinning, and easy to apply Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

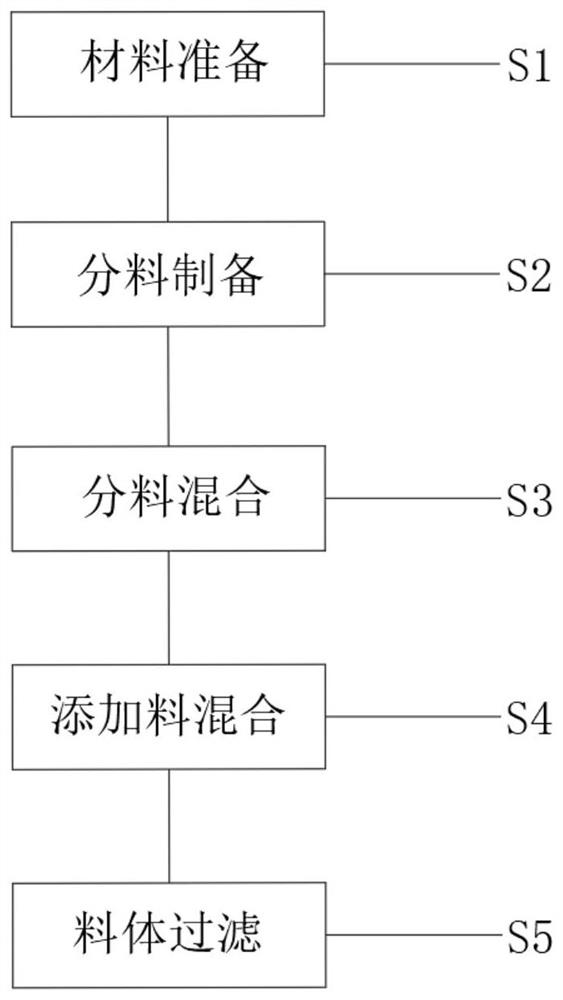

[0034] A production process for water-resistant, fireproof and thermal insulation coatings for building exterior walls, comprising the following steps:

[0035] S1: Material preparation: Prepare 5 parts of lignocellulose, 8 parts of calcium formate, 10 parts of ash calcium powder, 50 parts of Shuangfei powder, 3 parts of cellulose ether, 15 parts of phosphate, 10 parts of aluminum silicate fiber, and 7 parts of chemical additives 4 parts, 4 parts of deionized water, 5 parts of spherical hollow ceramic microspheres, 4 parts of amino cross-linking agent and 6 parts of chitosan sustained-release particles for subsequent use;

[0036] S2: Sub-material preparation: 5 parts of lignocellulose, 8 parts of calcium formate, 10 parts of ash calcium powder, 50 parts of Shuangfei powder and 3 parts of cellulose ether prepared in step S1 are placed in a mixing mixer for mixing and stirring. When mixing, control the rotating speed of the stirring shaft to be 500r / min, and the stirring time i...

Embodiment 2

[0042] A production process for water-resistant, fireproof and thermal insulation coatings for building exterior walls, comprising the following steps:

[0043] S1: Material preparation: Prepare 8 parts of lignocellulose, 10 parts of calcium formate, 13 parts of lime calcium powder, 55 parts of Shuangfei powder, 6 parts of cellulose ether, 17 parts of phosphate, 11 parts of aluminum silicate fiber, and 8 parts of chemical additives 6 parts, 6 parts of deionized water, 5 parts of spherical hollow ceramic microspheres, 6 parts of amino cross-linking agent and 8 parts of chitosan slow-release particles for subsequent use;

[0044] S2: Sub-material preparation: 8 parts of lignocellulose, 10 parts of calcium formate, 13 parts of ash calcium powder, 55 parts of Shuangfei powder and 6 parts of cellulose ether prepared in step S1 are placed in a mixing mixer for mixing and stirring. When mixing, control the rotating speed of the stirring shaft to be 500r / min, and the stirring time is ...

Embodiment 3

[0050] A production process for water-resistant, fireproof and thermal insulation coatings for building exterior walls, comprising the following steps:

[0051] S1: Material preparation: prepare 10 parts of lignocellulose, 12 parts of calcium formate, 15 parts of ash calcium powder, 60 parts of Shuangfei powder, 7 parts of cellulose ether, 18 parts of phosphate, 12 parts of aluminum silicate fiber, and 10 parts of chemical additives 8 parts, 8 parts of deionized water, 6 parts of spherical hollow ceramic microspheres, 8 parts of amino cross-linking agent and 10 parts of chitosan slow-release particles are used for subsequent use;

[0052] S2: Sub-material preparation: 10 parts of lignocellulose prepared in step S1, 12 parts of calcium formate, 15 parts of ash calcium powder, 60 parts of Shuangfei powder and 7 parts of cellulose ether are placed in a mixing mixer for mixing and stirring. When mixing, control the rotating speed of the stirring shaft to be 600r / min, and the stirr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com