Thickening agent, fracturing fluid, preparation method of fracturing fluid, gel breaking method of fracturing fluid and application method of fracturing fluid

An application method and thickening agent technology, applied in the field of fracturing fluid, can solve the problems of high viscosity of fracturing fluid, flocculent sedimentation, oil recovery without imbibition, etc., achieve strong oil washing, increase permeability, increase modification ability, The effect of changing the interfacial tension of oil and water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] Such as figure 1 Shown, the present invention also provides a kind of preparation method of thickener, comprises the following steps:

[0065] 1) stirring and mixing distilled water, fluorocarbon nonionic surfactant, cocamide betaine, and olefin sulfonate to obtain a first mixed solution;

[0066] 2) Then add nano-SiO to the first mixed solution 2 and graphene to obtain a second mixed solution, which is continuously stirred and oscillated to complete the preparation.

[0067] Preferably, in step 1) and step 2), each stirring speed is 2800r / min-3000r / min, each stirring time is 3min-5min, and the shaking time is 3min-5min.

[0068] Preferably, in step 2), the second mixed liquid is a homogeneous liquid or a liquid with precipitation, and the pH of the liquid is 4-8.

[0069] The present invention also provides a fracturing fluid, based on the mass of the fracturing fluid, the fracturing fluid comprises:

[0070] Mass percentage is the potassium chloride of 1.0%;

[0...

Embodiment 1

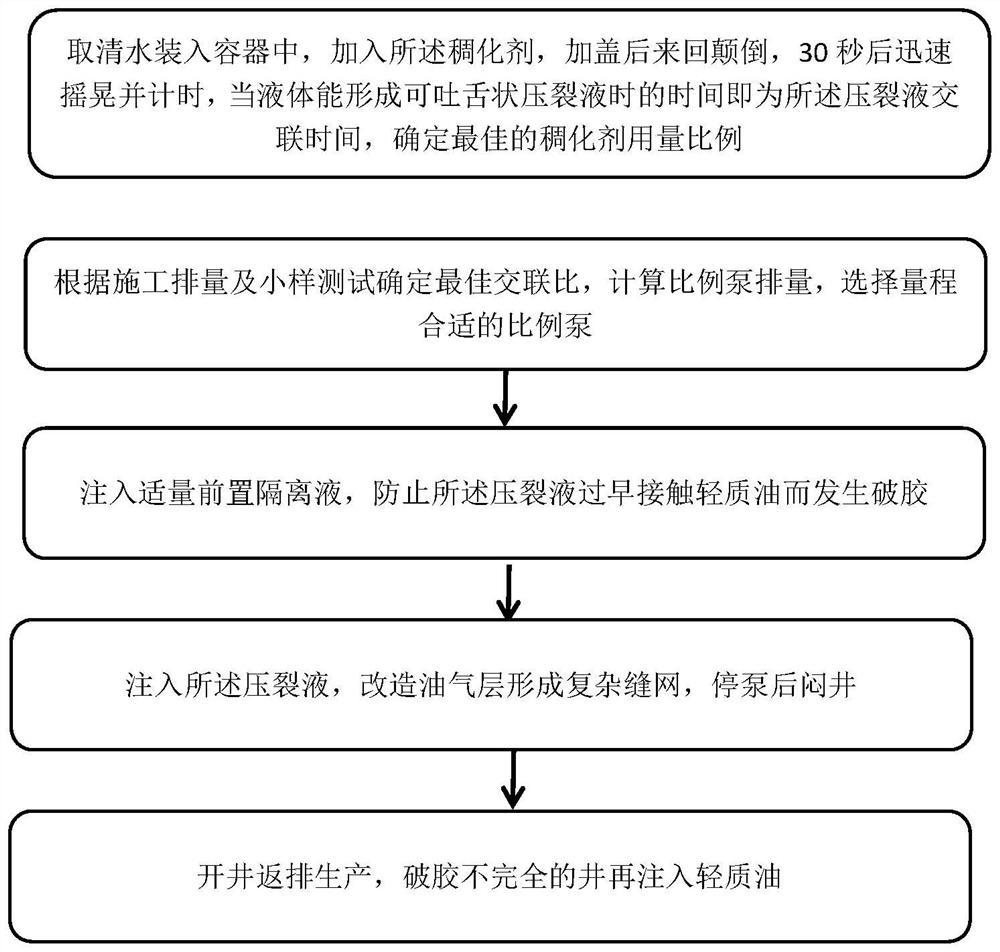

[0090] In this example, Well L49, a tight oil reservoir in the Chang 7 group in the Ordos Basin, is taken as an example. The specific implementation process is as follows:

[0091] Step 1: Prepare 93.8% distilled water, add 1% fluorocarbon non-ionic surfactant, 2% cocamide betaine, 1% olefin sulfonate and mix well; then slowly and evenly add 1.5% of the particle size range of 16nm nano-SiO 2 , 0.7% graphene, continuously stirring and vibrating to disperse until a surfactant-type thickener is obtained. During the preparation process, the stirring rate was 3000 r / min, and the stirring and vibration time was 4 minutes; the prepared thickener was homogeneous liquid, without precipitation, and had a pH value of 6.

[0092] Step 2: Take 250mL of clear water and put it into a plastic bottle, add 4mL of surfactant-type thickener, cover it upside down, shake it quickly after 30 seconds and count the time, when the liquid can form tongue-like fracturing fluid. To determine the optimal...

Embodiment 2

[0099] This example takes Well O33 in a tight oil reservoir in Songliao Basin as an example, and the specific implementation process is as follows:

[0100] Step 1: Prepare 89% distilled water, add 2% fluorocarbon nonionic surfactant, 4% cocamide betaine, 2% olefin sulfonate and mix well; then slowly and evenly add 2% nanometer particles with a particle size range of 17nm SiO 2 , 1% graphene, continuously stirring and vibrating to disperse until a surfactant-type thickener is obtained. During the preparation process, the stirring rate was 2800 r / min, and the stirring and vibration time was 4 minutes; the prepared thickener was homogeneous liquid, without precipitation, and had a pH value of 7.

[0101] Step 2: Take 300mL of clear water and put it into a plastic bottle, add 5mL of surfactant-type thickener, cover it upside down, shake it quickly after 30 seconds and count the time, when the liquid can form tongue-like fracturing fluid. To determine the optimal thickener dosag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com