Deep stope ventilation and refrigeration system utilizing return air

A stope and deep technology, applied in the field of ventilation and cooling system of deep metal mine stope, can solve the problems of high investment cost of central air-conditioning technology, inflexible stope environment, high pipeline pressure, etc., to avoid water supply difficulties and improve flexibility performance and increase the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

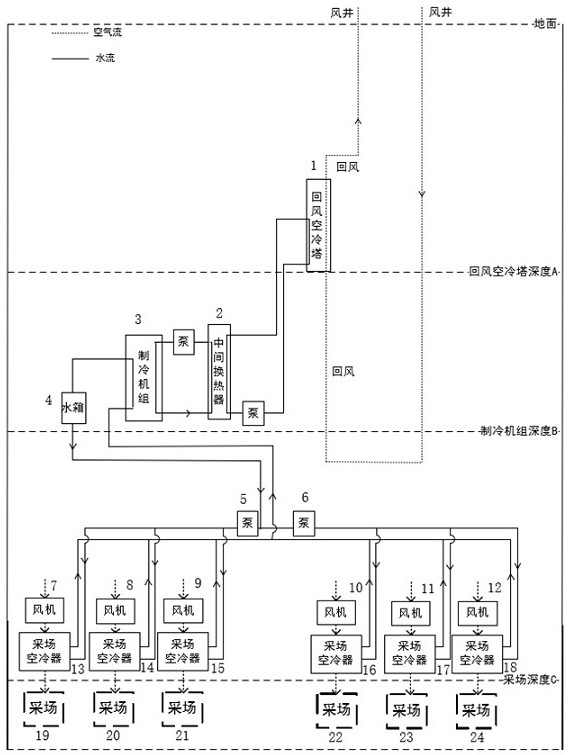

[0034] figure 1 A ventilation and cooling system for deep metal mine stope using return air is shown. Such as figure 1As shown, the system includes an air shaft, a return air cooling tower 1, a refrigeration unit 3, and stope air coolers 13-18. The fresh air is input into the mine from the air shaft, and then the return air passes through the return air cooling tower 1 for heat exchange. , the return air cools the hot water in the return air cooling tower 1, and the cooled hot water performs direct or indirect heat exchange with the refrigerant from the refrigeration unit 3, and the refrigerant in the refrigeration unit 3 is cooled with the air-cooled The hot water from the air cooler 13-18 is heat exchanged to cool the hot water from the air cooler, and the hot water from the air cooler enters the stope air cooler 13-18 after cooling, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com