Heat supply system capable of switching from extraction condensing to zero output of low-pressure cylinder and working method of heat supply system

A technology of heating system and working method, which is applied in steam engine installations, machines/engines, mechanical equipment, etc., can solve the problem of rigidity, poor flexibility, poor controllability of large-diameter heating butterfly valves, and heat extraction and steam regulation during the removal of low-pressure cylinders. The narrowing of the scope and other problems, to achieve the effect of flexible heating adjustment capacity, widening the adjustment scope, and simple implementation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0025] Example.

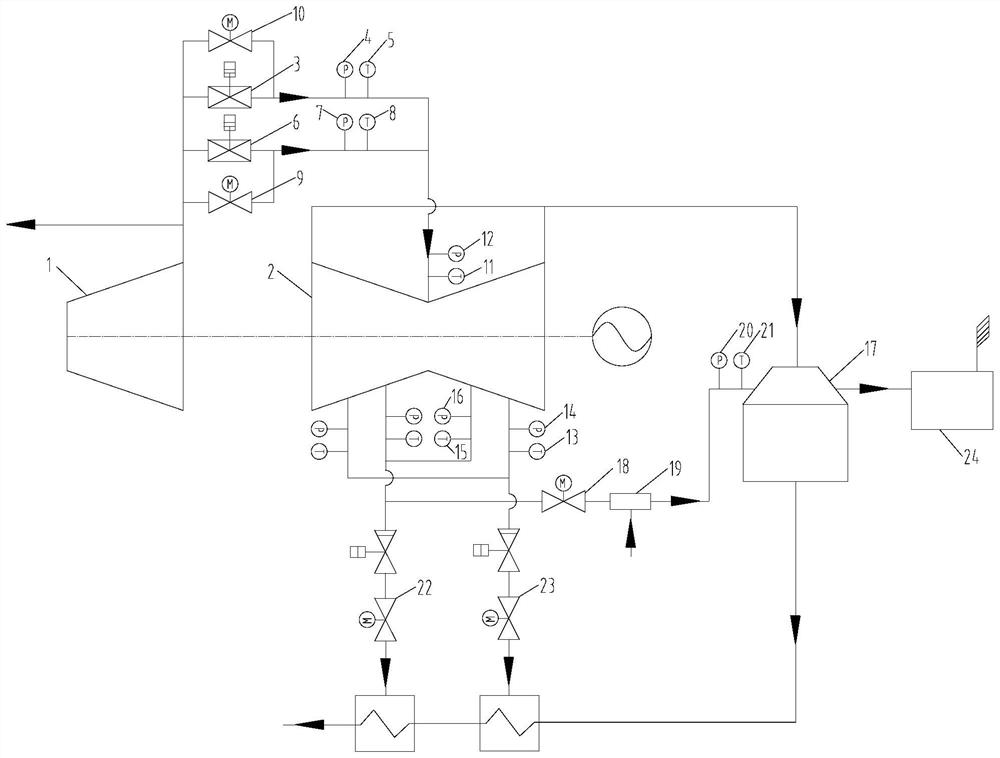

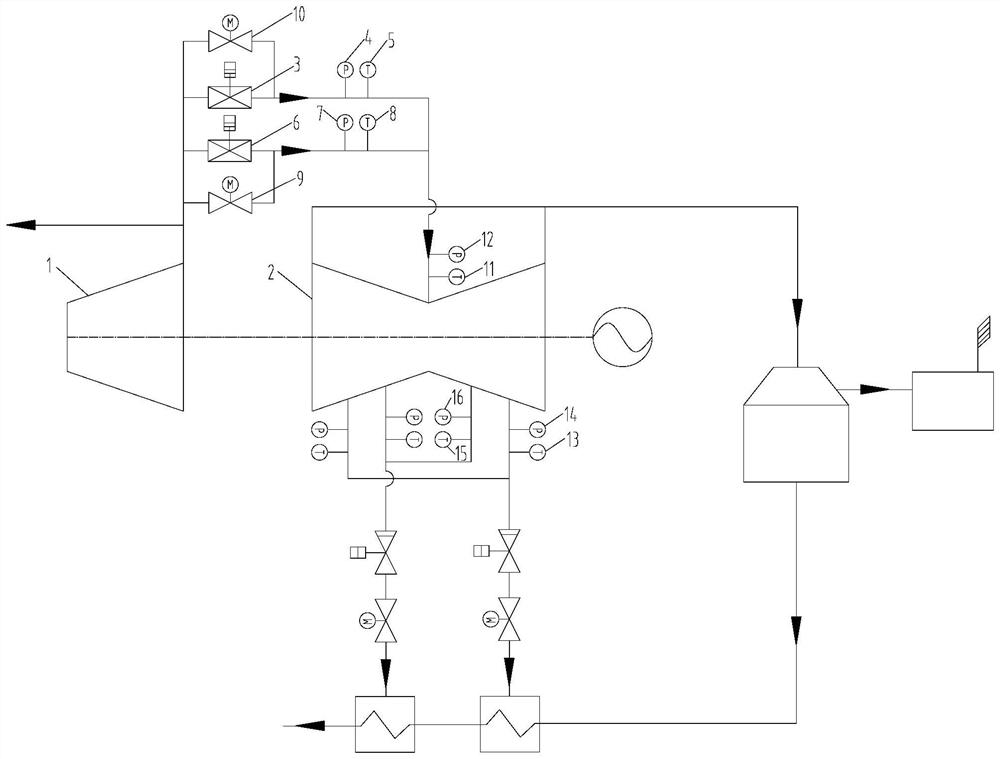

[0026] see Figure 1 to Figure 2 , in this embodiment, a heating system that switches from condensate extraction to low-pressure cylinder zero output, on the basis of the original condensate extraction heating system, a small-diameter communication pipe is added between the medium-pressure cylinder 1 and the low-pressure cylinder 2 , the small-diameter connecting pipeline is installed with a small-diameter heating control valve 3, a pressure sensor 4 and a temperature sensor 5 in sequence, the small-diameter heating control valve 3 is connected in parallel with the original heating butterfly valve 6, and the original heating butterfly valve 6 A pressure sensor 2 7 and a temperature sensor 2 8 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com