Early warning method and device for leakage accident of furnace tube of thermal power plant

A technology for thermal power plants and furnace tubes, used in boiler smoke pipes/fire pipes, components of steam boilers, steam boilers, etc., can solve the problems of inconvenient warning methods and devices, insufficient accuracy, and high false alarm rate, and achieve early Early warning of accident time, high accuracy, and the effect of recovering economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

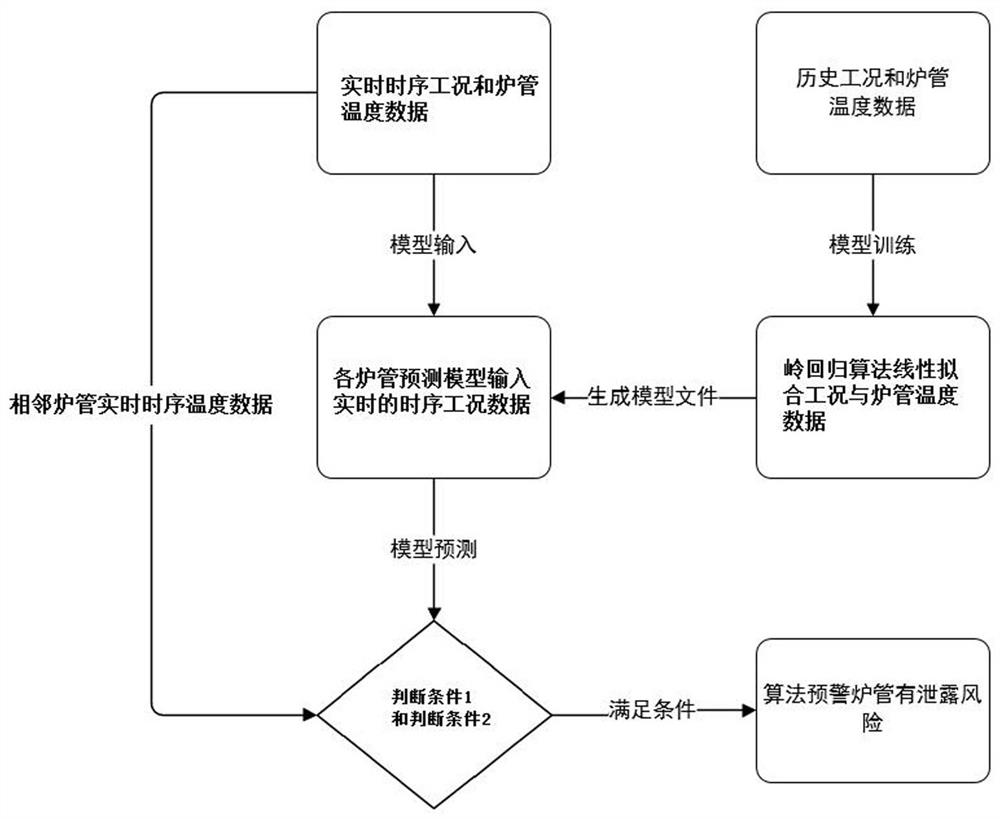

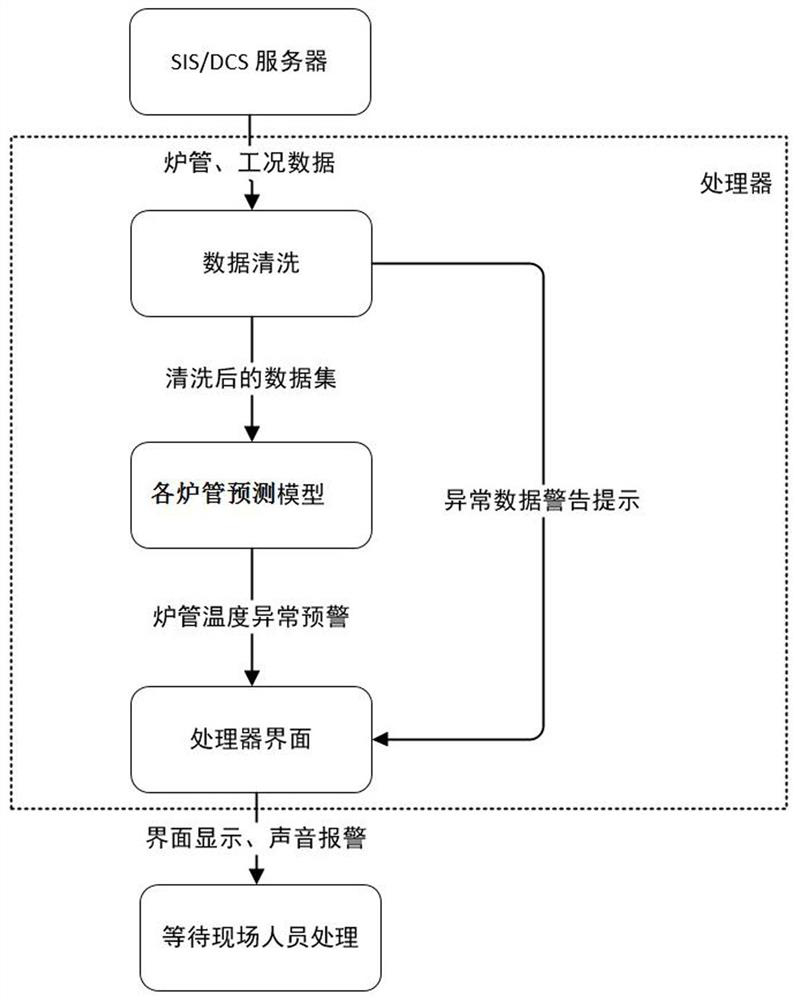

[0044] This embodiment provides an early warning method for furnace tube leakage accidents in thermal power plants. The early warning method is a method for predicting, judging and early warning for the wall temperature of all furnace tubes of the four boiler tubes (boiler water wall, superheater, reheater and economizer). Cooperate figure 1 , 2 As shown, it mainly uses the ridge regression model to predict the temperature of the furnace tube and combines the temperature data of adjacent furnace tubes in space to comprehensively judge the state of the furnace tube.

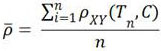

[0045] The method includes: S1. Invoking each furnace tube prediction model based on the ridge regression algorithm to linearly fit working conditions and furnace tube temperature data. S2: Use each furnace tube prediction model to predict the temperature of the furnace tube in real time: the input of the model is the time series working condition data; the output of the model is the time series temperature data...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com