High-temperature heat radiation type explosion-proof heater and control system

A control system and heater technology, applied in the control of fluid heaters, air heaters, fluid heaters, etc., can solve the problems of increase, long procurement cycle, and increased equipment size and volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

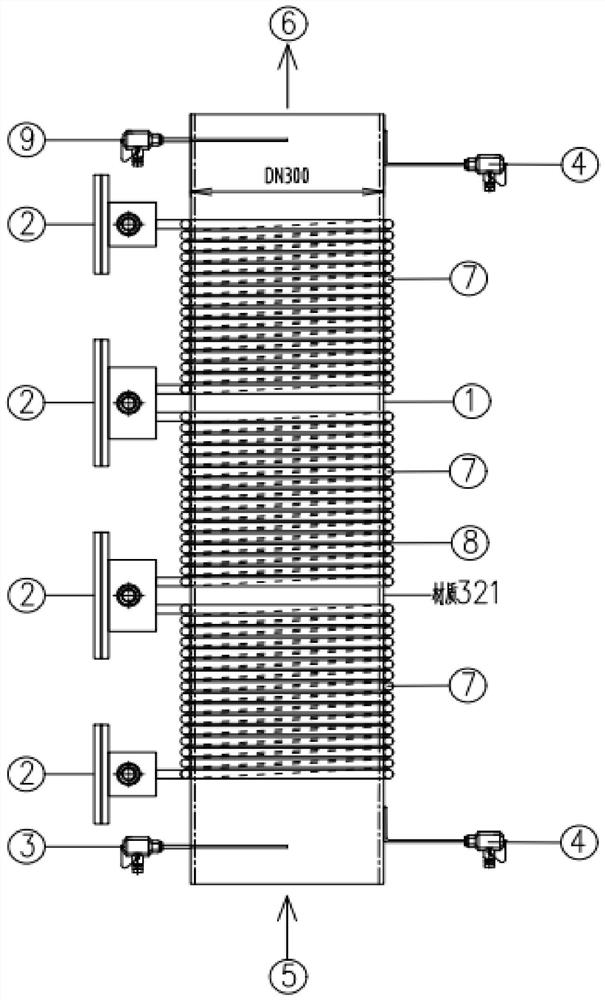

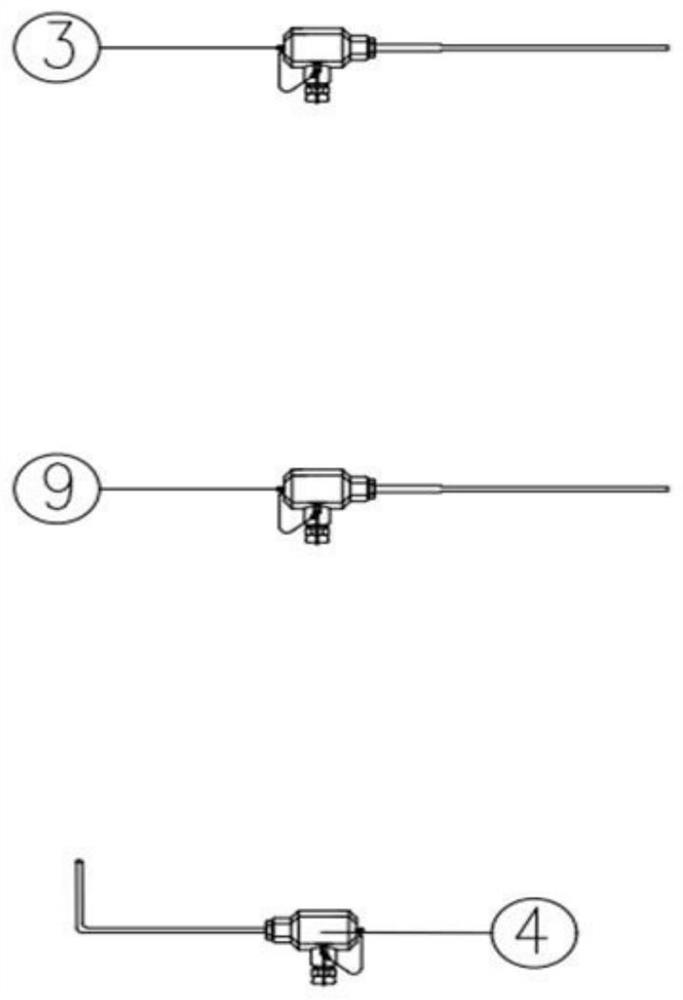

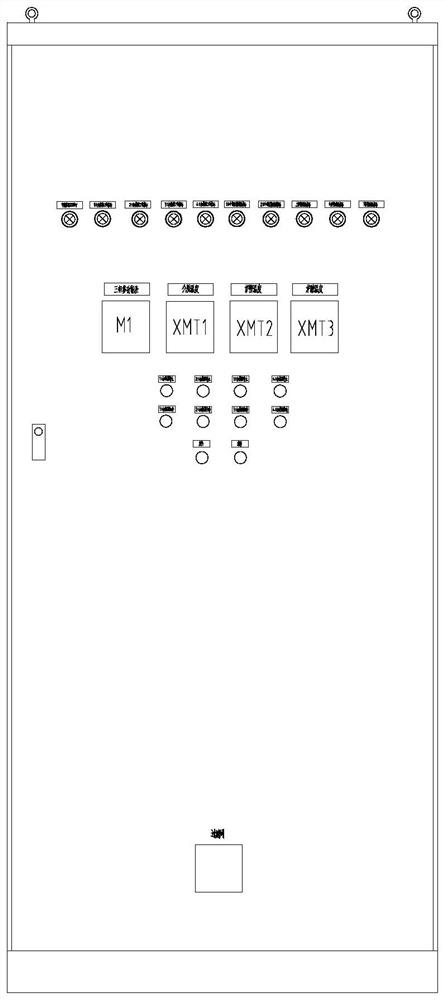

[0025] The structure of this embodiment is as Figure 1-2 As shown, the high-temperature radiation type explosion-proof electric heater heating device includes a pressure pipe shell (material TP321) 1 and a metal tubular electric heating element 7 tightly wound on the outer circumference of the process pressure pipe (diameter φ6mm, material TP310S or Incoloy800, etc.), The insulation performance is excellent at high temperature, and the withstand strength is high, and it is not easy to deform. The metal tubular heating element 7 and the bottom plate of the explosion-proof wiring chamber are assembled and formed by argon arc welding after drilling, and multiple explosion-proof wiring chambers 2 (design It is fixed by detachable type) for easy maintenance. Process gas inlet 5 and gas outlet 6 are equipped with process gas inlet temperature monitoring point 3 (explosion-proof K-type double thermocouple) and outlet temperature monitoring point 9 (explosion-proof K-type double ther...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com