Two-stage refrigeration liquefier and organic solvent recovery method and system

A secondary refrigeration and organic solvent technology, applied in refrigeration and liquefaction, chemical instruments and methods, refrigerators, etc., can solve the problems of inability to achieve full recovery of organic solvents, inability to realize organic solvent reuse, inability to meet environmental protection policies, etc. Achieve the effects of prolonging cooling time, promoting gas liquefaction, and high cycle efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Adopt above-mentioned a kind of organic solvent recovery method, be used for the treatment of the waste gas containing organic solvent of coating machine or printing factory, comprise the following steps:

[0081] Step S1, installing an axial flow booster fan on the exhaust gas collection pipeline of the coating machine or the printing factory to pressurize the exhaust gas to 0.15MPa;

[0082] Step S2, the pressurized exhaust gas enters the normal temperature water cooling heat exchanger, and the temperature is lowered from 60-80°C to 30-40°C;

[0083] Step S3, further remove the moisture in the waste gas by double-layer drier until the moisture content is 0.02-0.03g / m 3 ;

[0084] Step S4, after drying, the exhaust gas is passed into the regenerator to exchange heat with the exhaust gas of the secondary refrigeration liquefier for pre-cooling, and the temperature drops to 0-5°C;

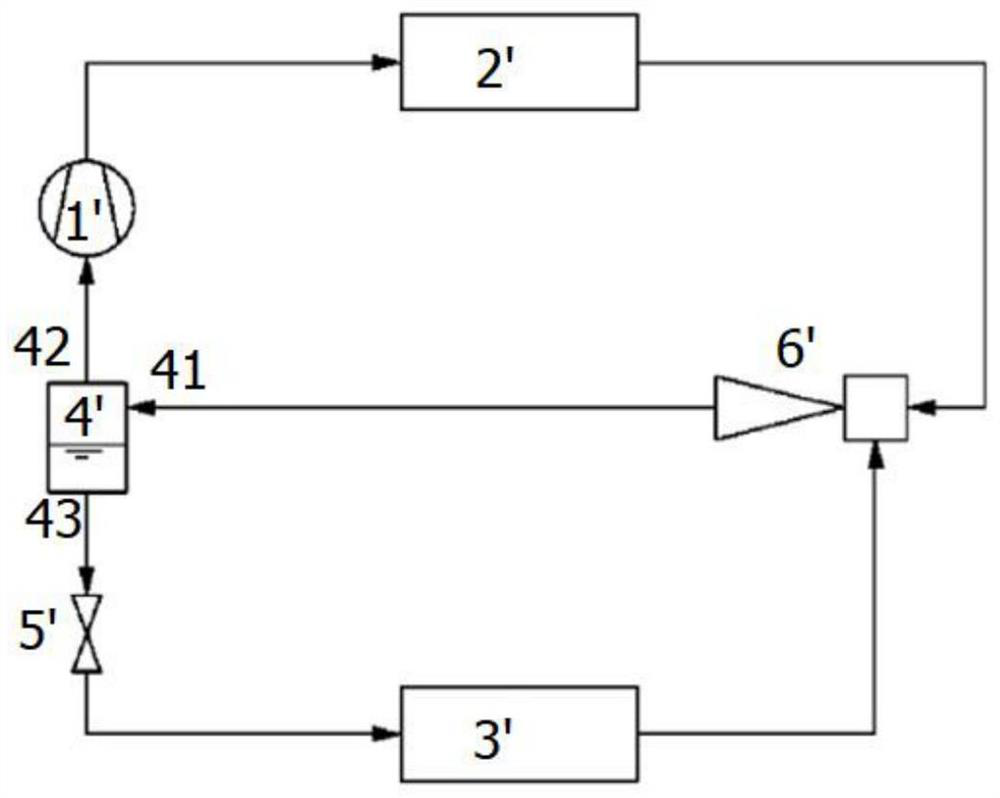

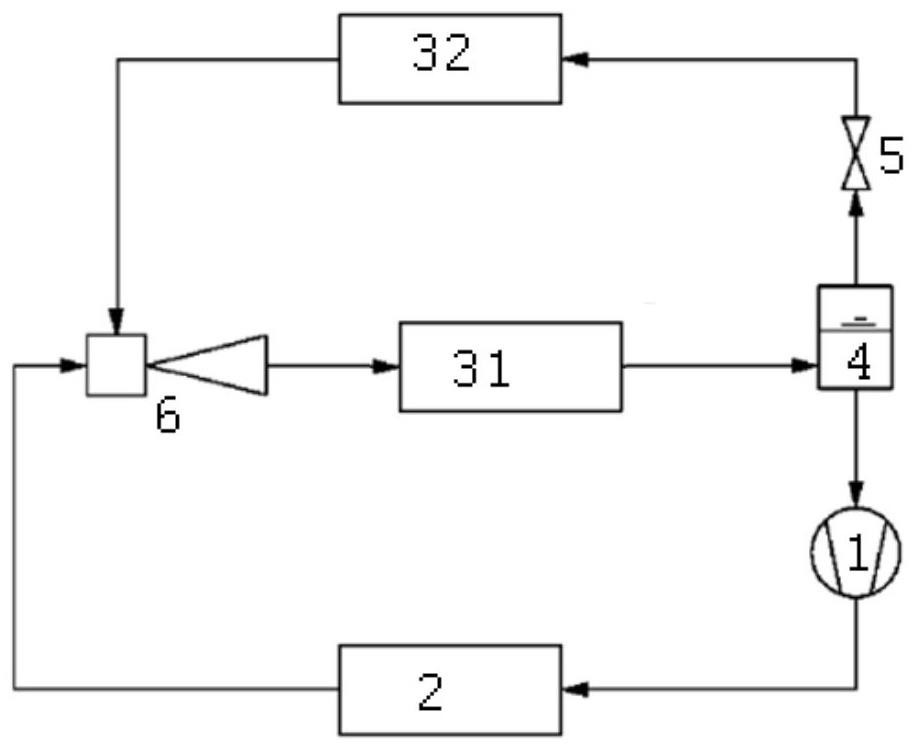

[0085] Step S5. After precooling, the exhaust gas is sent to the secondary refrigeratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com