Coke oven flue gas treatment pipeline for dust removal, desulfurization and denitrification

A flue gas treatment, desulfurization and denitrification technology, applied in waste heat treatment, furnace, furnace components, etc., can solve the problems of excessive particulate matter, filter hole blockage, unfavorable flue gas emission, etc., to improve heat exchange effect, facilitate cooling, and facilitate desulfurization The effect of denitrification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

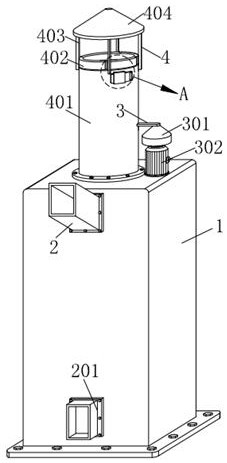

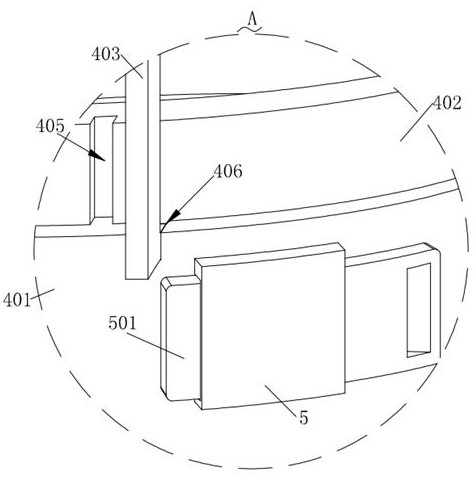

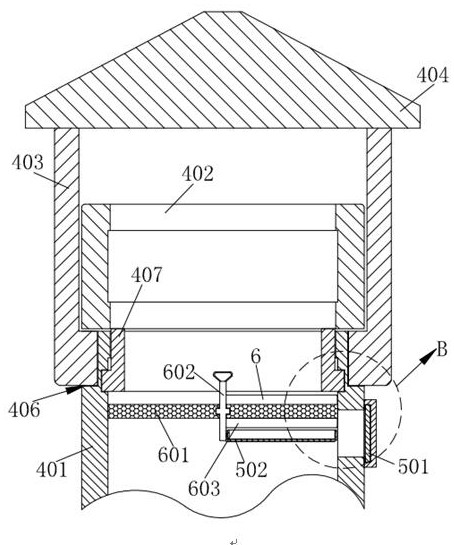

[0032] Such as Figure 1-Figure 9 As shown, a coke oven flue gas treatment pipeline for dust removal, desulfurization and denitrification according to the present invention includes an outer pipeline 1, and a cooling mechanism 2 for cooling flue gas is installed on the outer pipeline 1, and the outer pipeline 1 A cleaning mechanism 3 for cleaning the ammonium bisulfate condensed on the cooling mechanism 2 is installed on the top, the cleaning mechanism 3 conflicts with the cooling mechanism 2, and a smoke exhaust mechanism 4 is installed on the outer pipeline 1, and the smoke exhaust mechanism 4 A dust scraping mechanism 6 for filtering particulate matter in the flue gas is installed on the top, and a collection mechanism 5 for collecting dust is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com