Flowing heat exchange experimental device for micro-tube bundle precooler

A precooler, thermal experiment technology, applied in the testing of measuring devices, instruments, machines/structural components, etc. The complex heat transfer mechanism of the precooler can reduce the contact thermal resistance and improve the temperature measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below with reference to the accompanying drawings and examples.

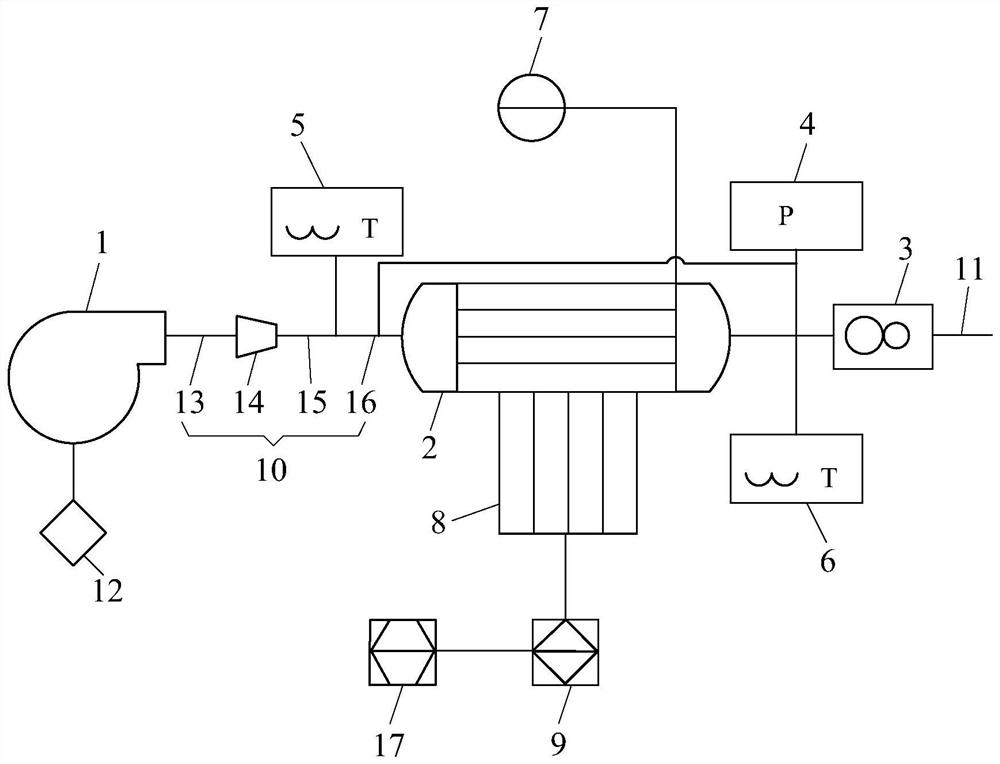

[0039] The embodiment of the present invention provides a flow heat exchange experimental device for a microtube bundle precooler, such as figure 1 As shown, the experimental device includes a fan 1, a microtube bundle test unit 2, a flowmeter 3, a differential pressure gauge 4, an inlet temperature sensor 5, an outlet temperature sensor 6, a variable voltage DC power supply 7, a thermocouple 8 and a data acquisition instrument 9;

[0040] The air inlet of the micro tube bundle test unit 2 communicates with the fan 1 through the air intake pipeline 10, and the air outlet is connected with an exhaust pipeline 11; the fan 1 is used to generate air flow, and the air flow enters the micro tube bundle test unit 2 for heat exchange with the micro tube bundle ; The microtube bundle test unit 2 can be a box structure with a length of 148mm, a width of 120mm, and a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap