Improved micro impedance measurement self-calibration algorithm and device

A technology of impedance measurement and self-calibration, applied in the direction of measuring devices, measuring electrical variables, material resistance, etc., can solve problems such as unguaranteed, data record overflow, unsatisfactory measurement results, etc., and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

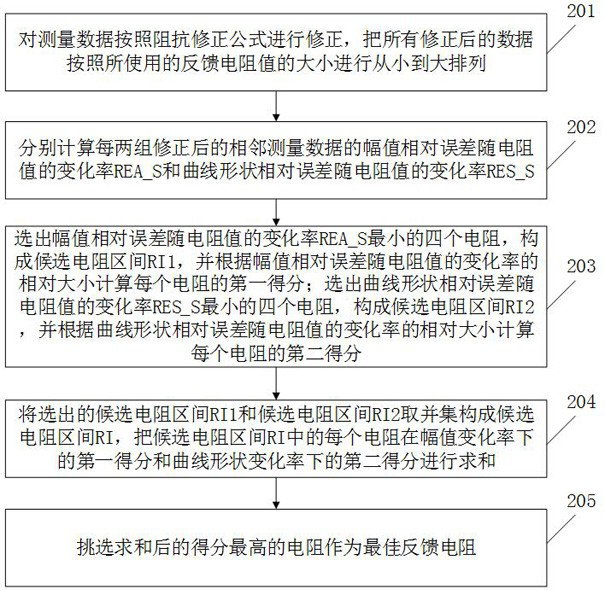

[0068] Embodiment 1 of the present invention provides an improved miniature impedance measurement self-calibration algorithm, such as figure 1 shown, including:

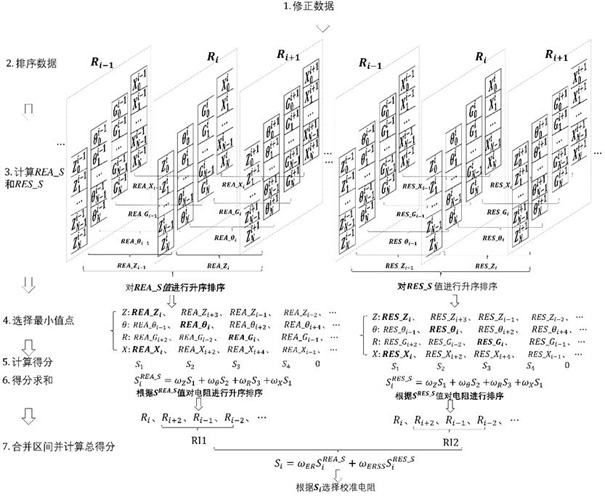

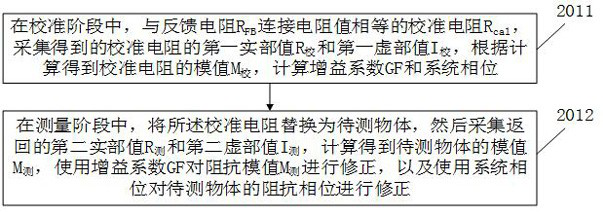

[0069] In step 201, the measured data is corrected according to the impedance correction formula, and all the corrected data are arranged in ascending order according to the value of the feedback resistance used.

[0070] In a certain implementation process, different feedback resistors can be used to calibrate and measure the object to be measured based on the AD5933, and the calibration data of the calibration stage and the measurement data of the measurement stage under multiple sets of feedback resistors can be obtained.

[0071] In step 202 , the rate of change REA_S of the relative error of the magnitude with respect to the resistance value and the rate of change of the relative error of the curve shape with the value of the resistance RES_S of each group of corrected adjacent measurement data are calculated re...

Embodiment 2

[0112] In the field of structural health monitoring, when using a micro-impedance measurement device for damage monitoring based on the impedance method, generally a piezoelectric ceramic transducer (Piezoelectric Transducer, abbreviated as: PZT) is connected to the micro-impedance measurement device first, and then the piezoelectric The electric ceramic transducer PZT is pasted on the object to be monitored, and then, based on a specific algorithm, the miniature impedance measurement device can automatically measure the impedance of the object to be monitored. The traditional algorithm that helps miniature impedance measuring equipment to perform automatic measurement includes a gain coefficient calibration method. The difference between the gain coefficient calibration method and the self-calibration algorithm of the present invention will be compared in detail below.

[0113] First, 25 feedback resistors are used to measure the impedance of an iron bar in the [50kHz, 60kHz] fr...

Embodiment 3

[0145] Such as Figure 16 As shown, it is a schematic diagram of the structure of the improved miniature impedance measurement self-calibration device of the embodiment of the present invention. The improved miniature impedance measurement self-calibration device of this embodiment includes one or more processors 21 and memory 22 . in, Figure 16 A processor 21 is taken as an example.

[0146] Processor 21 and memory 22 can be connected by bus or other means, Figure 16 Take connection via bus as an example.

[0147] The memory 22, as a non-volatile computer-readable storage medium, can be used to store non-volatile software programs and non-volatile computer-executable programs, such as the improved miniature impedance measurement self-calibration method in Embodiment 1. Processor 21 executes the improved miniature impedance measurement self-calibration method by running non-volatile software programs and instructions stored in memory 22 .

[0148] The memory 22 may incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com