Low-power rate type lithium ion battery

A lithium-ion battery and rate technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problem of not having both high rate and high safety performance, and achieve high binder content, fast charging performance improvement, and adhesion. The effect of strong knot strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

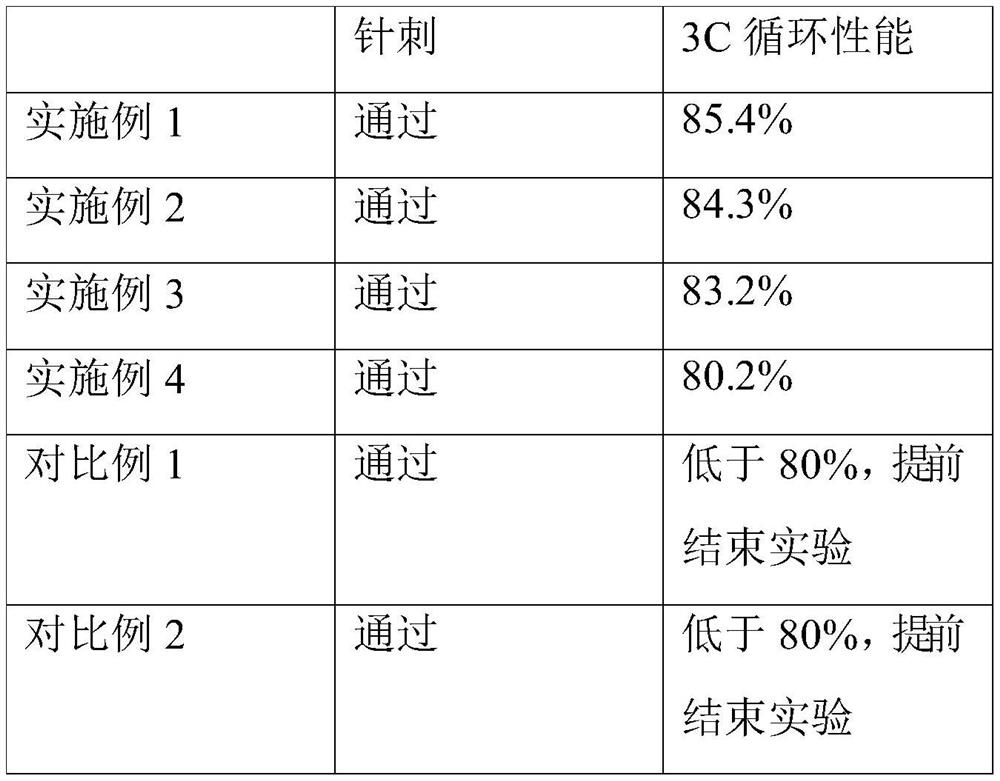

Examples

Embodiment approach

[0055] As an embodiment, the solid electrolyte particle may be a quasi-solid electrolyte, which contains a mixture of the non-aqueous liquid electrolyte solution and the solid electrolyte system detailed above, for example, including one or more ionic liquids and one or more A metal oxide particle (such as, aluminum oxide (Al 2 o 3 ) and / or silicon dioxide (SiO 2 )).

[0056] The second aspect of the present application provides a low-power high-rate lithium-ion battery, which includes a positive electrode, an electrolyte, and the aforementioned negative electrode.

[0057] Lithium-ion batteries are capable of generating electric current during discharge by reversible electrochemical reactions that occur when an external circuit is closed (to connect the negative and positive electrodes) and the negative electrode contains a relatively greater amount of available lithium. The chemical potential difference between the positive and negative electrodes drives the electrons gen...

Embodiment 1

[0080] In the embodiment of the present application, a rate-type lithium-ion battery is provided, especially a lithium-ion battery suitable for low-power fast charging, including a positive electrode structure and a negative electrode structure, and the negative electrode structure includes a current collector and an active negative electrode disposed on the current collector. material layer and a solid electrolyte layer, and the solid electrolyte layer is arranged on the negative electrode active material layer, the surface of the current collector is covered with a conductive layer, and the conductive layer is obtained by coating the conductive paste on the surface of the current collector through a carbon coating process. The negative electrode active material layer includes the first A negative electrode active material layer.

[0081] The graphene in the conductive paste is composed of 25wt% graphene with a particle size of 160nm and 70wt% graphene with a particle size of ...

Embodiment 2

[0085] The difference from Example 1 is that the first negative electrode active material layer is composed of 94.3wt% artificial graphite, 2.7wt% PVDF and 3wt% CNTs, and the second negative electrode active material layer is covered by 95.2wt% surface Composition of fast-charging graphite, 1.8wt% PVDF and 3wt% CNTs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com