Modified solid oxide fuel cell electrode, in-situ solvothermal preparation method thereof and solid oxide fuel cell

A fuel cell electrode, solid oxide technology, applied in fuel cells, battery electrodes, circuits, etc., can solve the problems of complex steps, electrode damage, long time consumption, etc., and achieve excellent electrochemical performance and polarization resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0070] The invention provides a method for preparing a modified solid oxide fuel cell electrode, which is characterized in comprising the following steps:

[0071] 1) After mixing the metal salt solution and the pH regulator, a precursor reaction solution is obtained;

[0072] 2) placing the solid oxide fuel cell or the electrode of the solid oxide fuel cell in the precursor reaction solution obtained in the above steps, and vacuumizing to obtain a reaction system;

[0073] 3) Put the reaction system obtained in the above steps into a reaction device, and perform a solvothermal reaction to obtain a modified solid oxide fuel cell electrode.

[0074] In the present invention, the selection, composition and structure of the materials in the above preparation method, as well as the corresponding optimization principles, can preferably correspond to the selection, composition and structure, and the corresponding optimization principles of the aforementioned modified solid oxide fue...

Embodiment 1

[0107] (1) 0.25g of Ce(NO 3 ) 3 ·6H 2 O was dissolved in 30 mL of ethylene glycol, then 1 mL of deionized water and 1 mL of propionic acid were added, and stirred until the solid was completely dissolved to obtain the solution required for solvothermal;

[0108] (2) Put the symmetric battery with the structure of LSCF / GDC / YSZ / GDC / LSCF prepared in advance into the lining of 50mL polytetrafluoroethylene, and slowly pour the solution in step (1) into the polytetrafluoroethylene In the lining, the battery is completely submerged in the solution, and then evacuated to -30k Pa;

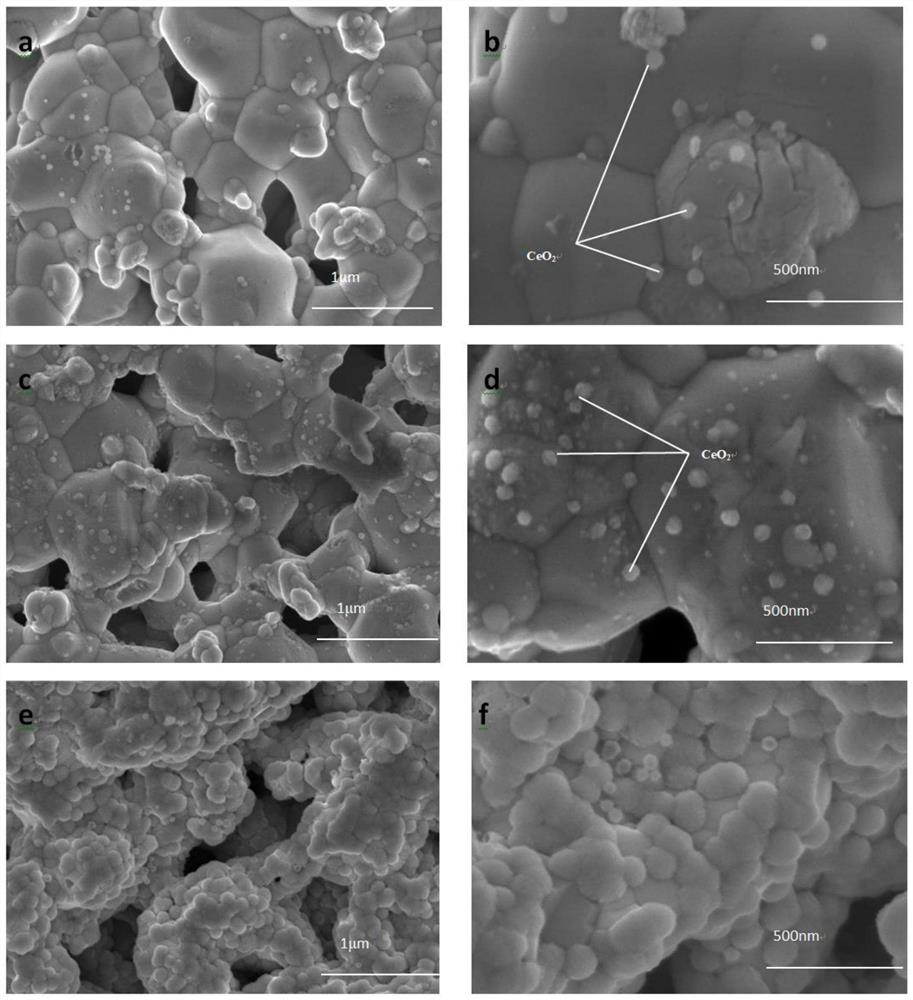

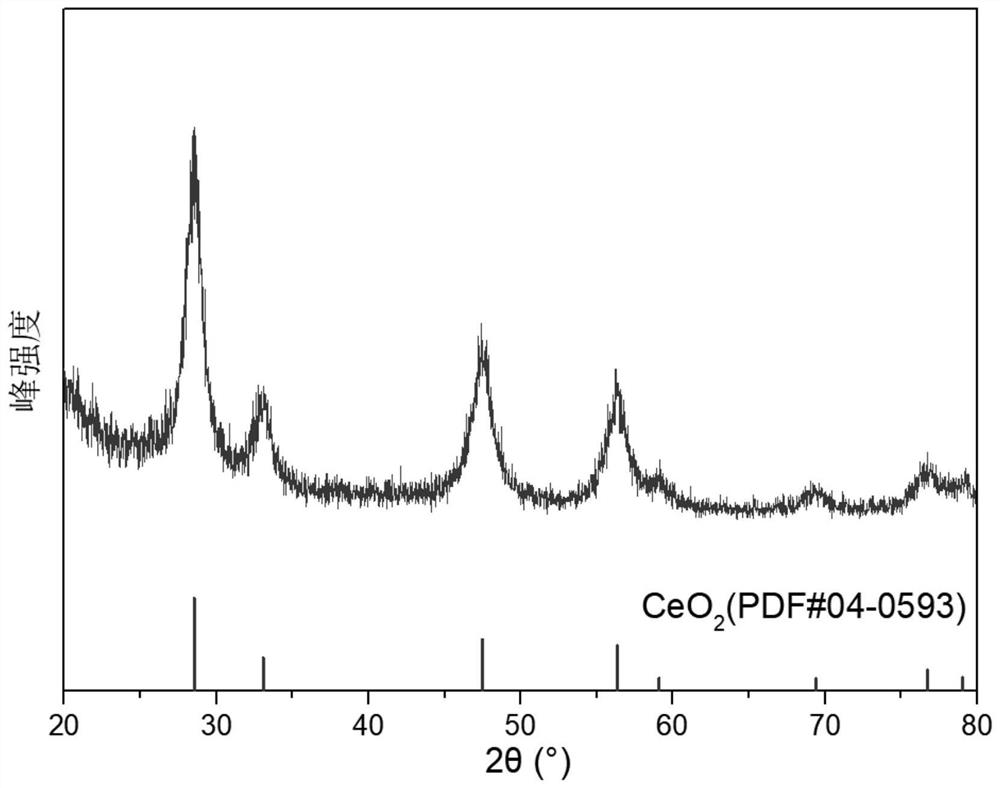

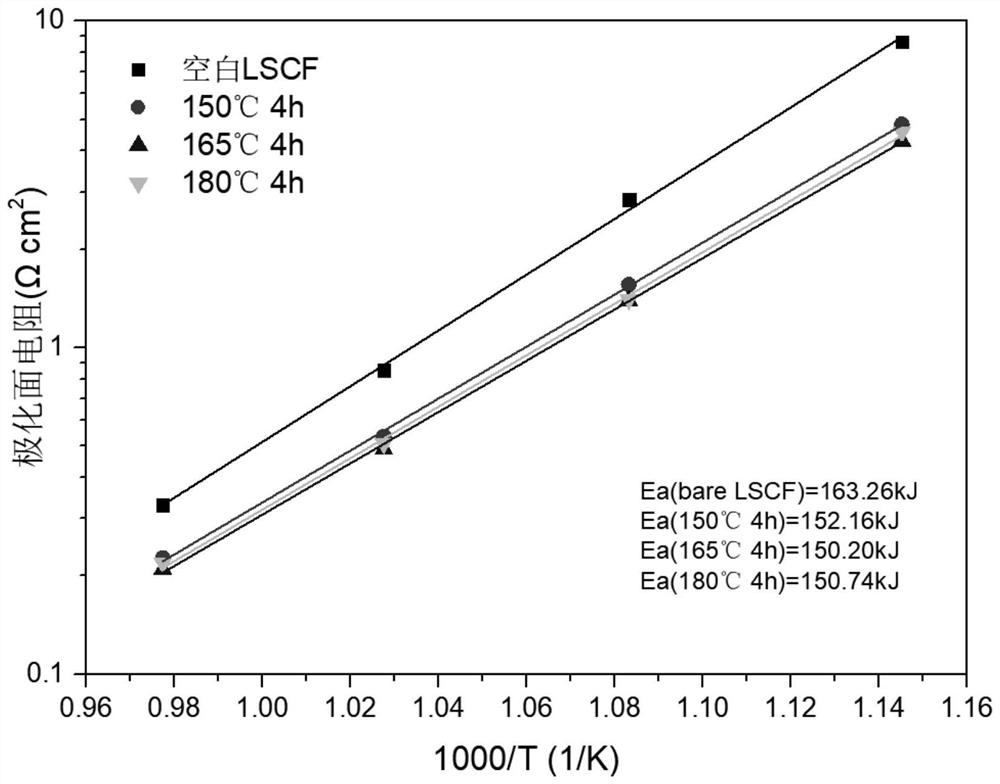

[0109] (3) Transfer the polytetrafluoroethylene lining in step (2) to a stainless steel hydrothermal reaction kettle, and seal the reaction kettle tightly. Put the reaction kettle in an oven and raise the temperature to 150°C ~ 180°C, and keep it warm for 4 hours, CeO 2 Nanoparticles will grow in situ on the surface of the LSCF electrode;

[0110] (4) Take the symmetrical battery out of the solution, w...

Embodiment 2

[0119] (1) 0.25g of Ce(NO 3 ) 3 ·6H 2 O, 0.0284g Sm(NO 3 ) 3 ·6H 2 O was dissolved in 30 mL of ethylene glycol, then 1 mL of deionized water and 1 mL of propionic acid were added, and stirred until the solid was completely dissolved to obtain the solution required for solvothermal;

[0120] (2) Put the symmetric battery with the structure of LSCF / GDC / YSZ / GDC / LSCF prepared in advance into the lining of 50mL polytetrafluoroethylene, and slowly pour the solution in step (1) into the polytetrafluoroethylene In the lining, the battery is completely submerged in the solution, and then evacuated to -30k Pa;

[0121] (3) Transfer the polytetrafluoroethylene lining in step (2) to a stainless steel hydrothermal reaction kettle, and seal the reaction kettle tightly. Place the reaction kettle in an oven and heat up to 180°C, and keep it warm for 2 hours, Sm 0.1 Ce 0.9 o 2 Nanoparticles will grow in situ on the surface of the LSCF electrode;

[0122] (4) Take the symmetrical batt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Polarization resistance | aaaaa | aaaaa |

| Polarization resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com