One-time forming production process for glass fiber reinforced plastic septic tank

A glass tempering and production process technology, applied in the direction of biological sludge treatment, coating, etc., can solve the problems of inconvenient firing and curing work, inconvenient cycle flow work, inconvenient limit adjustment, etc., to facilitate production and processing work, realize The effect of barrier connection and convenient heating and curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

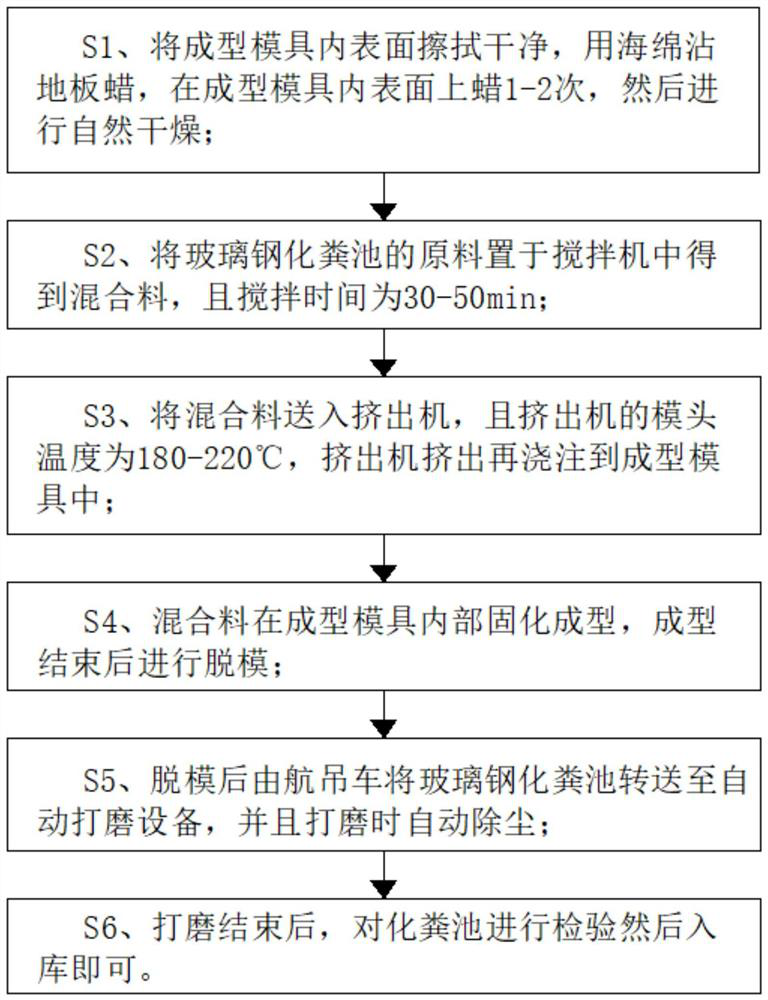

[0054] One-time forming production process of FRP septic tank, refer to figure 1 , including the following steps:

[0055] S1. Wipe the inner surface of the forming mold clean, dip the floor wax with a sponge, wax the inner surface of the forming mold twice, and then dry it naturally;

[0056] S2, placing the raw materials of the FRP septic tank in a mixer to obtain a mixture, and the mixing time is 30 minutes;

[0057] S3. Send the mixture into the extruder, and the temperature of the die head of the extruder is 190° C., extruded by the extruder and poured into the forming mold;

[0058] S4. The mixture is solidified and formed inside the forming mold, and demolded after the forming is completed;

[0059] S5. After demoulding, the FRP septic tank is transferred to the automatic grinding equipment by the aerial crane, and the dust is automatically removed during grinding;

[0060] S6. After finishing the polishing, inspect the septic tank and put it into storage.

[0061] ...

Embodiment 2

[0063] One-time forming production process of FRP septic tank, refer to figure 1 , including the following steps:

[0064] S1. Wipe the inner surface of the forming mold clean, dip the floor wax with a sponge, wax the inner surface of the forming mold twice, and then dry it naturally;

[0065] S2, placing the raw materials of the FRP septic tank in a mixer to obtain a mixture, and the mixing time is 40 minutes;

[0066] S3. Send the mixture into the extruder, and the temperature of the die head of the extruder is 220° C., extruded by the extruder and then poured into the forming mold;

[0067] S4. The mixture is solidified and formed inside the forming mold, and demolded after the forming is completed;

[0068] S5. After demoulding, the FRP septic tank is transferred to the automatic grinding equipment by the aerial crane, and the dust is automatically removed during grinding;

[0069] S6. After finishing the polishing, inspect the septic tank and put it into storage.

[0...

Embodiment 3

[0072] One-time forming production process of FRP septic tank, refer to figure 1 , including the following steps:

[0073] S1. Wipe the inner surface of the forming mold clean, dip the floor wax with a sponge, wax the inner surface of the forming mold twice, and then dry it naturally;

[0074] S2, placing the raw materials of the FRP septic tank in a mixer to obtain a mixture, and the mixing time is 50 minutes;

[0075] S3. Send the mixture into the extruder, and the temperature of the die head of the extruder is 200°C, extrude from the extruder and then pour into the forming mold;

[0076] S4. The mixture is solidified and formed inside the forming mold, and demolded after the forming is completed;

[0077] S5. After demoulding, the FRP septic tank is transferred to the automatic grinding equipment by the aerial crane, and the dust is automatically removed during grinding;

[0078] S6. After finishing the polishing, inspect the septic tank and put it into storage.

[0079...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com