Battery series-parallel connection switching main circuit, system and method without power output interruption

A main circuit and circuit technology, applied in the field of circuit devices, can solve the problems of contact erosion, arc flashover erosion, high current impact, etc., achieve good power acceleration performance and driving experience, and eliminate arc flashover and burning. Corrosion, eliminate the effect of high current impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0087] The formation and use of some embodiments will be described in detail below in conjunction with the accompanying drawings. The embodiments described herein with respect to the accompanying drawings are illustrative, diagrammatic and are used to provide a basic understanding of the invention. The specific embodiments described are merely illustrative of specific ways to make and use the invention, and do not limit the scope of the invention.

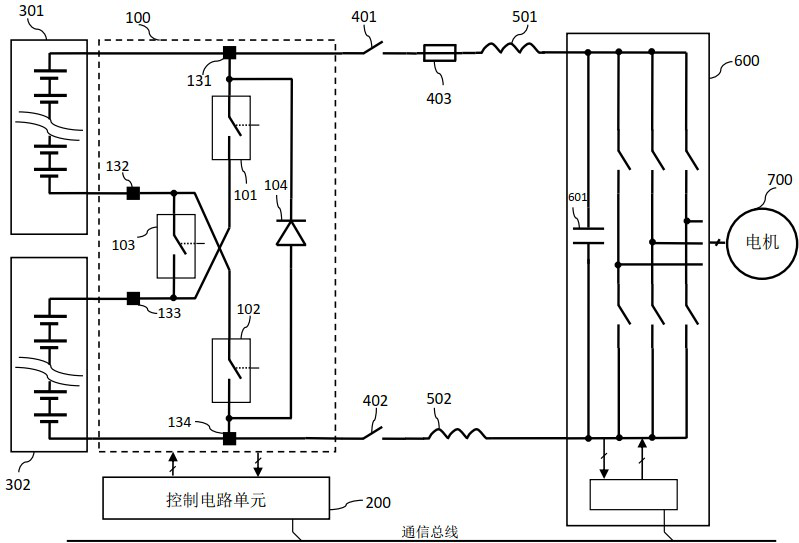

[0088] In the embodiment of the present invention figure 1 middle, figure 1 The shown series-parallel switching main circuit 100 is the basis of the present invention, and the main circuit 100 includes:

[0089] the first battery positive terminal 131, which is electrically coupled to the positive terminal of the first battery module 301;

[0090] the first battery negative terminal 132, which is electrically coupled to the negative terminal of the first battery module 301;

[0091] the second battery positive terminal 133, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com