Lithium battery positive electrode material and preparation method thereof

A cathode material, lithium battery technology, applied in battery electrodes, active material electrodes, chemical instruments and methods, etc., to achieve easy control, improve low-temperature electrochemical performance, and reduce low-temperature impedance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] This embodiment provides a method for preparing a lithium battery positive electrode material, comprising the following steps:

[0084] (1) Take 148.68g Li 2 CO 3 , 224.93g Fe 2 o 3 , 600g (NH 4 ) 3 PO 4 , 104.96gMnO 2 , dissolved in a solution containing complexing agent, mixed evenly, and prepared LiMn by liquid phase method 0.3 Fe 0.7 PO 4 Precursor.

[0085] The complexing agent can be one or more of citric acid, tartaric acid, succinic acid, oxalic acid, sulfosalicylic acid and lactic acid, and citric acid is used in this embodiment.

[0086] (2) LiMn 0.3 Fe 0.7 PO 4 The precursor is added to water and mixed evenly. The ratio of the precursor to water is: the amount of water used is 100% of the mass of the precursor; then sand milled, and then passed through a 3000-mesh sieve, and the obtained filtrate is the slurry.

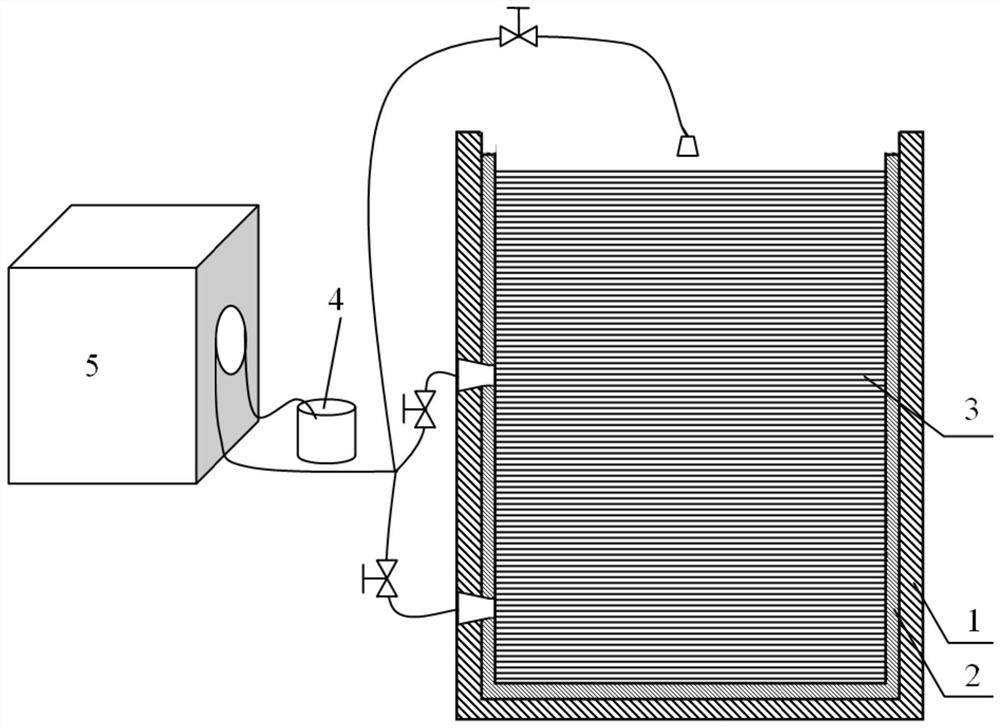

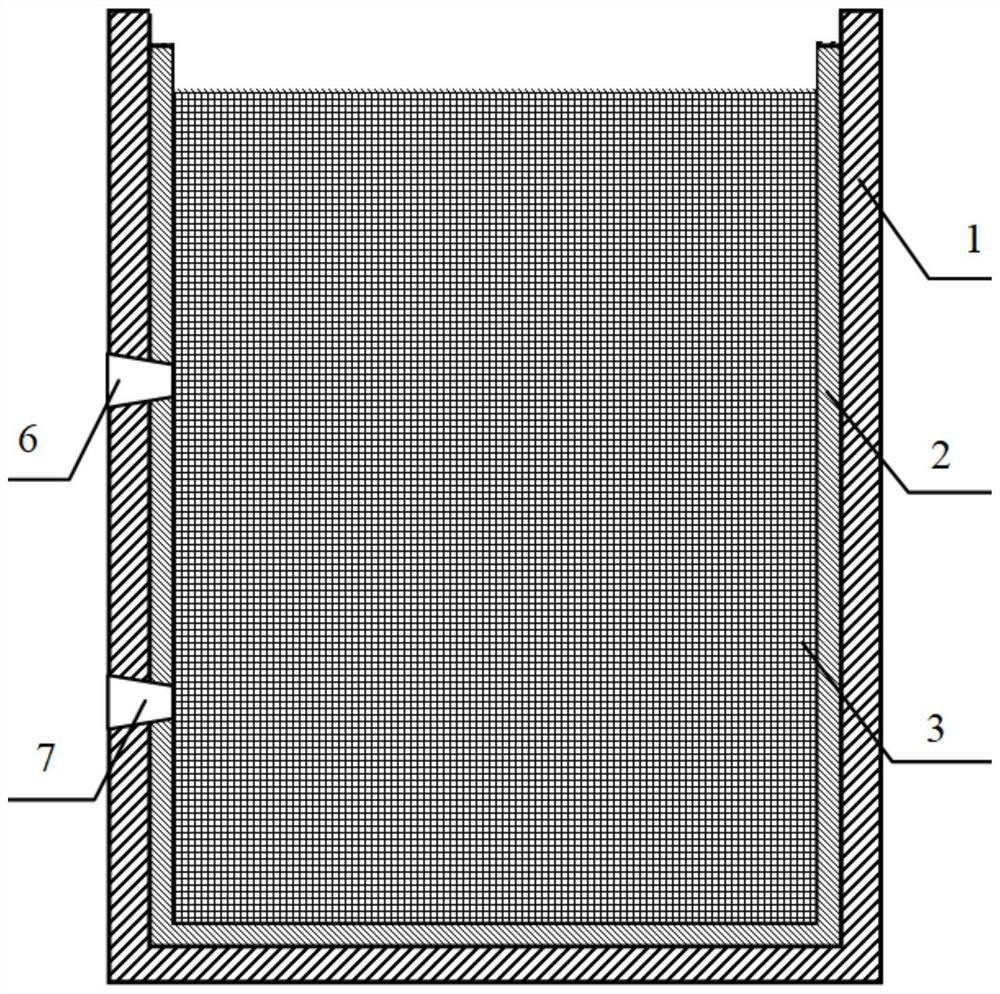

[0087] (3) The filtrate was pumped into the reaction kettle with a carbon material three-dimensional grid by a metering pump at a rate...

Embodiment 2

[0099] This embodiment provides a method for preparing a lithium battery positive electrode material, comprising the following steps:

[0100] (1) Take 148.68g Li 2 CO 3 , 224.93g Fe 2 o 3 , 600g (NH 4 ) 3 PO 4 , 104.96gMnO 2 , dissolved in a solution containing citric acid and mixed evenly, and the LiMn was obtained by the liquid phase method 0.3 Fe 0.7 PO 4 Precursor.

[0101] (2) LiMn 0.3 Fe 0.7 PO 4 Add the precursor to water, the ratio of the precursor to water is: the amount of water is 150% of the mass of the precursor, then add 25.89g of sucrose and mix evenly, sand mill and pass through a 3000-mesh screen to obtain the filtrate, which is the slurry .

[0102] (3) The filtrate is pumped from the upper, middle and lower parts of the reactor by a metering pump at a speed of 1mL / min. The reactor used is the same as in Example 1, and the carbon material three-dimensional grid 3 is formed by interconnecting carbon fiber filaments with a diameter of 3nm. netwo...

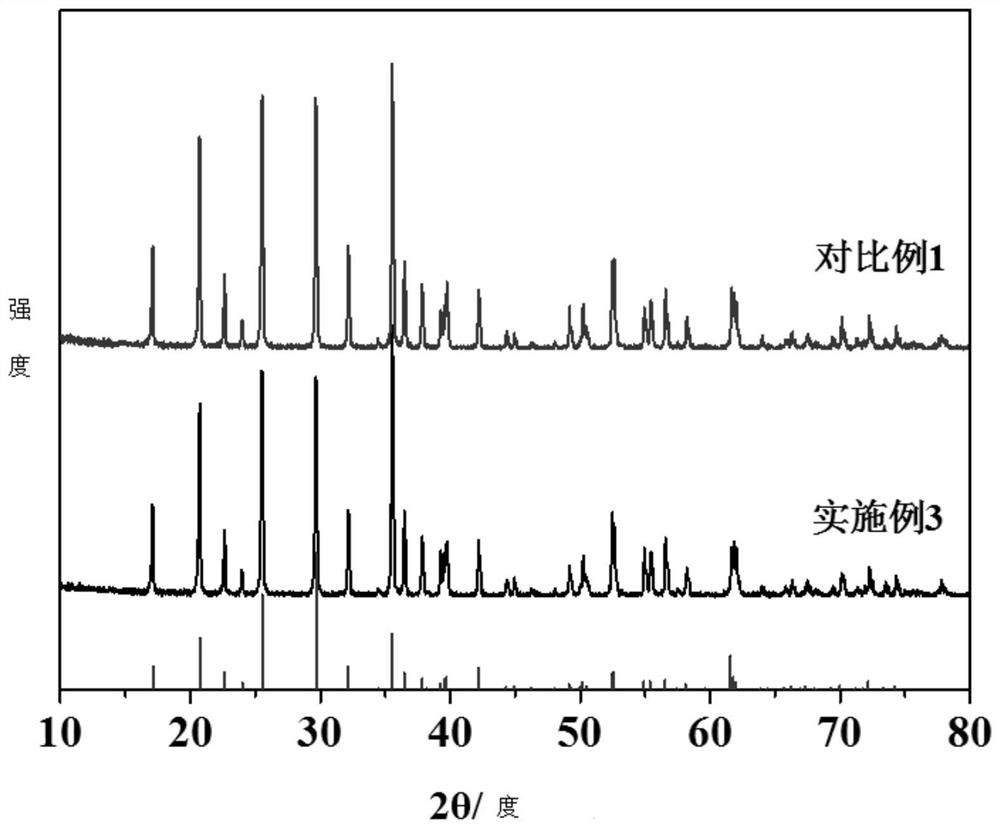

Embodiment 3

[0105] This embodiment provides a method for preparing a lithium battery positive electrode material, comprising the following steps:

[0106] (1) Take 727.51g Li 2 CO 3 , 1493.66g Fe 2 o 3 , 4000g (NH 4 ) 3 PO 4 , 85.60gMnO 2 , dissolved in a solution containing citric acid, mixed evenly, and prepared LiMn by liquid phase method 0.05 Fe 0.95 PO 4 Precursor.

[0107] (2) LiMn 0.05 Fe 0.95 PO 4 Add the precursor to water, and the ratio of the precursor to water is as follows: the amount of water is 100% of the mass of the precursor, and then 75.68g of glucose is added to mix evenly, sand-milled and passed through a 2500-mesh sieve, and the obtained filtrate is the slurry.

[0108] (3) The filtrate is pumped from the upper, middle and lower parts of the reactor by a metering pump at a speed of 1mL / min. The reactor used is the same as in Example 1, and the carbon material three-dimensional grid 3 is formed by interconnecting carbon fiber filaments with a diameter of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com