Modified imidazoline quaternary ammonium salt type asphalt warm mixing agent and preparation method thereof

The technology of imidazoline quaternary ammonium salt and imidazoline is applied in the field of preparation of road asphalt additives, which can solve the problems of poor universality, high price of warm-mixing agents, few types, etc., and achieves simple and easy-to-obtain cost and remarkable cooling effect. , the effect of adding less amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

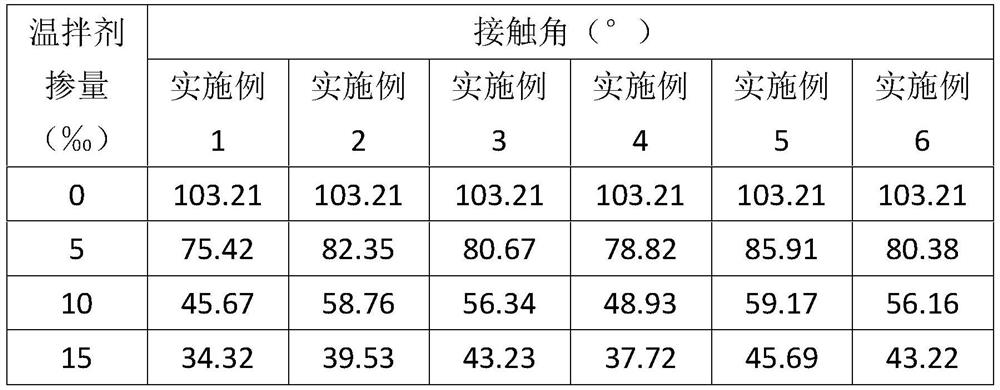

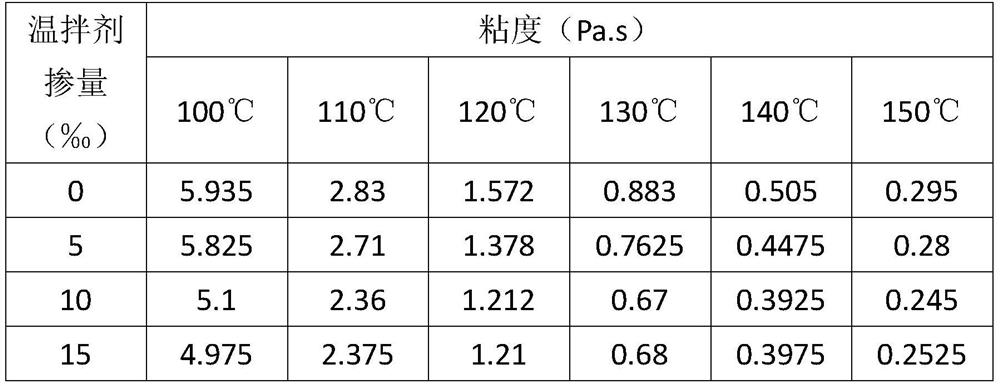

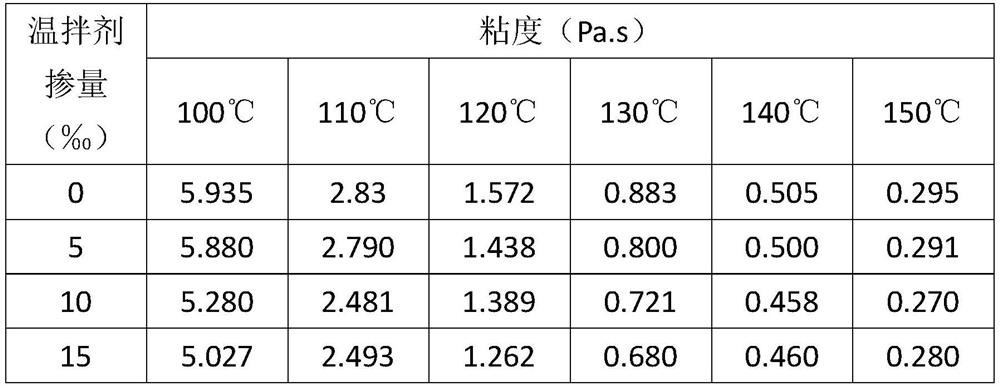

Examples

Embodiment 1

[0035] Add tall oil and diethylenetriamine with a molar ratio of 1:1 into the reactor, and add a certain amount of water-carrying agent toluene, accounting for 20% of the total mass. Stir and heat up to reflux, amidation reaction occurs at the reflux temperature, the reaction temperature is 150°C, and the reaction takes 4 hours. Evaporate the xylene, evacuate to a vacuum degree of 0.095MPa and raise the temperature to 240°C for cyclization reaction for 5h to obtain an imidazoline intermediate. Prepare a 50% ethanol solution with methyl acrylate in a molar ratio of 1:1.2 to the imidazoline intermediate, slowly add it dropwise to the imidazoline, and react for 12 hours under stirring at 40°C. The methyl acrylate of reaction, obtains product, is warm mixing agent product of the present invention.

Embodiment 2

[0037] Add tall oil and diethylenetriamine with a molar ratio of 1:1.2 into the reactor, and add a certain amount of water-carrying agent xylene, accounting for 30% of the total mass. Stir and heat up to reflux, amidation reaction occurs at the reflux temperature, the reaction temperature is 140°C, and the reaction takes 4 hours. Evaporate the xylene, evacuate to a vacuum degree of 0.095 MPa and raise the temperature to 240°C for cyclization reaction for 4 hours to obtain an imidazoline intermediate. Prepare a 50% ethanol solution with methyl acrylate in a molar ratio of 1:1.2 to the imidazoline intermediate, slowly add it dropwise to the imidazoline, and react for 12 hours under stirring at 40°C. The methyl acrylate of reaction, obtains product, is warm mixing agent product of the present invention.

Embodiment 3

[0039] Add tall oil and diethylenetriamine with a molar ratio of 1:1.4 into the reactor, and add a certain amount of water-carrying agent toluene, accounting for 40% of the total mass. Stir and heat up to reflux, amidation reaction occurs at the reflux temperature, the reaction temperature is 150°C, and the reaction takes 4 hours. Evaporate the xylene, evacuate to a vacuum degree of 0.095 MPa and raise the temperature to 240°C for cyclization reaction for 4 hours to obtain an imidazoline intermediate. Prepare a 50% ethanol solution with methyl acrylate in a molar ratio of 1:1.2 to the imidazoline intermediate, slowly add it dropwise to the imidazoline, and react for 12 hours under stirring at 40°C. The methyl acrylate of reaction, obtains product, is warm mixing agent product of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com