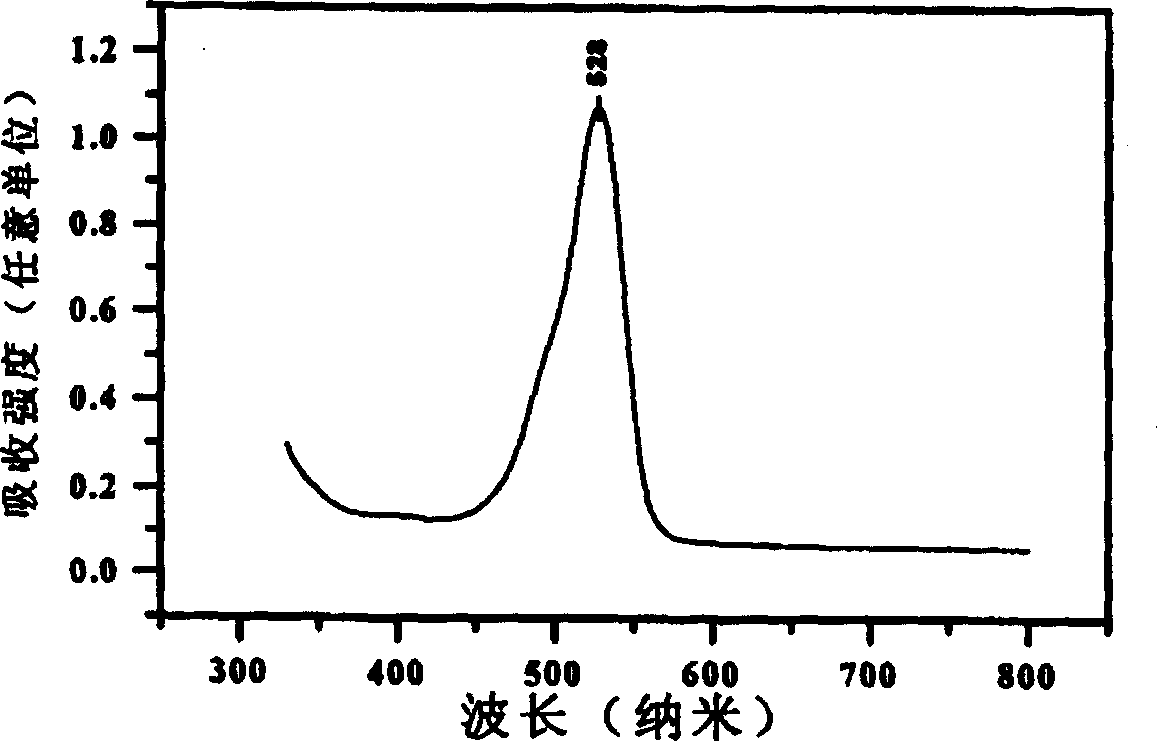

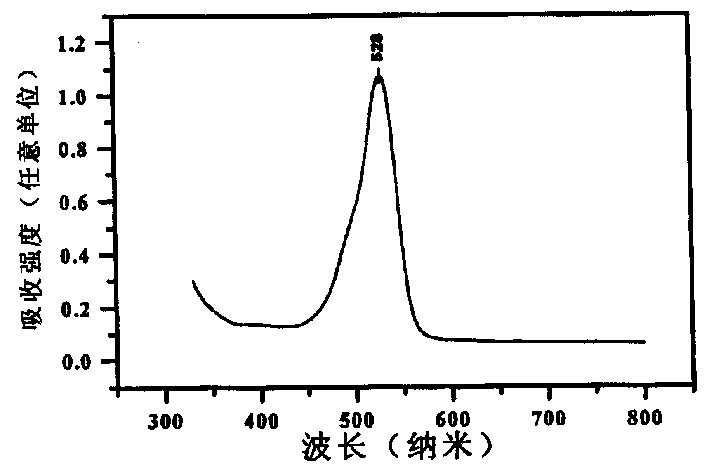

Photopolymer holographic recording material sesitive to green light and its preparation method

A holographic recording material and photopolymer technology, which is applied in the direction of photomechanical equipment, photoplate making process of patterned surface, optics, etc., can solve the problems of difficult repeatability and poor repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: Prepare according to the above-mentioned specific preparation process, and finally the prepared photopolymer dry film component content is:

[0023] Polyvinyl alcohol: 60wt%

[0024] Acrylamide: 10.4wt%

[0025] Methylenebisacrylamide: 5.3wt%.

[0026] Triethanolamine: 24.2wt%

[0027] Phycoerythrin B: 0.1wt%

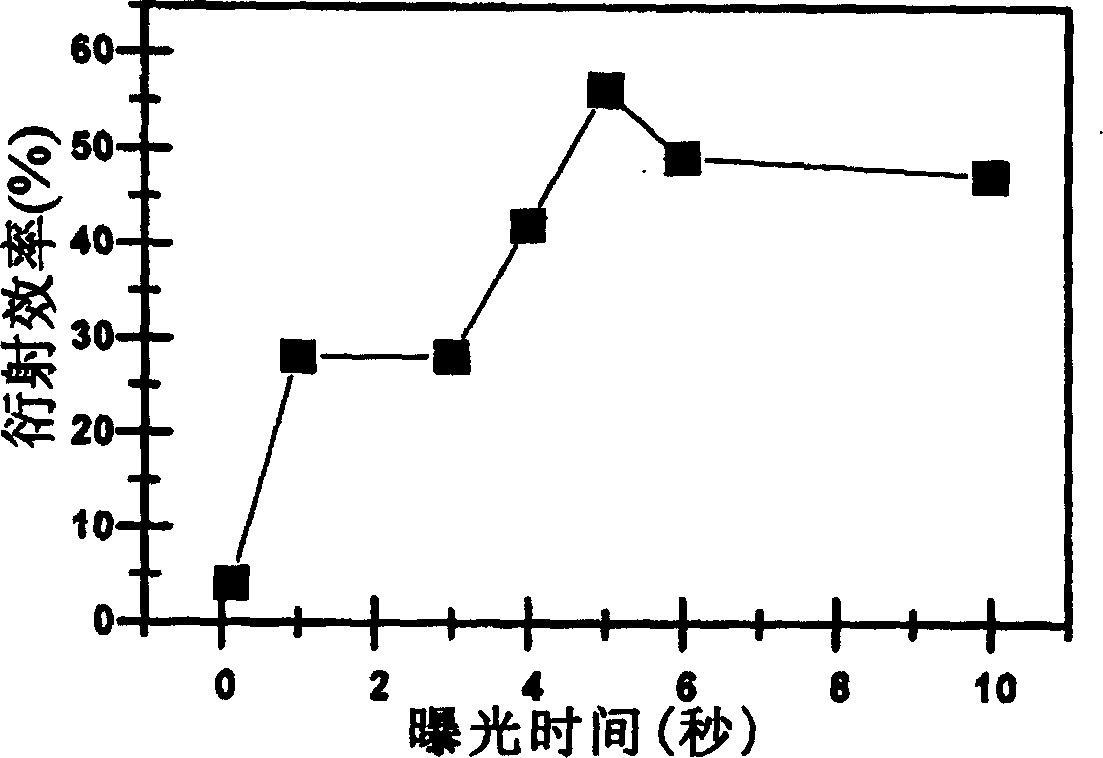

[0028] The obtained diffraction efficiencies are as figure 2 As shown, greater than 60%.

Embodiment 2

[0029] Embodiment 2: Prepare according to the above-mentioned specific preparation process, and finally the prepared photopolymer dry film component content is:

[0030] Polyvinyl alcohol: 50wt%.

[0031] Acrylamide: 12wt%

[0032] Methylenebisacrylamide: 4%wt%

[0033] Triethanolamine: 33.8wt%

[0034] Phycoerythrin B: 0.2wt%

[0035] The diffraction efficiency obtained in this embodiment is greater than 90%, which can be said to be the best way to realize the present invention.

Embodiment 3

[0036] Embodiment 3: Prepare according to the above-mentioned specific preparation process, and finally the prepared photopolymer dry film component content is:

[0037] Polyvinyl alcohol: 40wt%

[0038] Acrylamide: 14.5wt%

[0039] Methylenebisacrylamide: 5.3wt%

[0040] Triethanolamine: 40wt%

[0041] Phycoerythrin B: 0.2wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com