Online monitoring system for blade lead breakage of wind generating set and positive and negative testing method

A wind turbine and blade lead wire technology, which is applied in wind turbine monitoring, wind turbines, wind power generation, etc., can solve problems such as the immaturity of detection and judgment technology, reduce the probability of large-scale failures, be easy to implement, and ensure safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

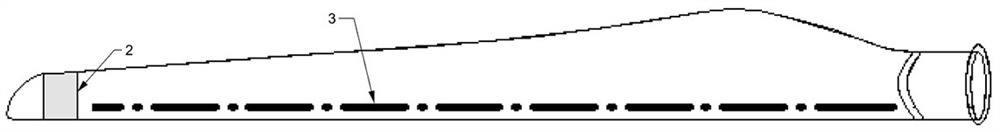

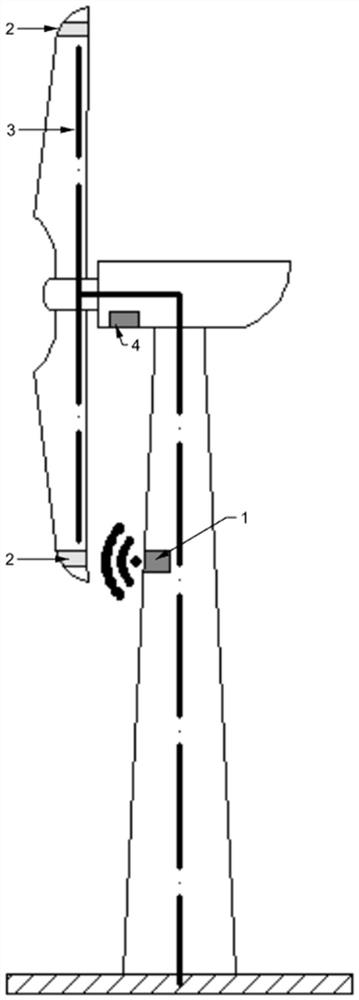

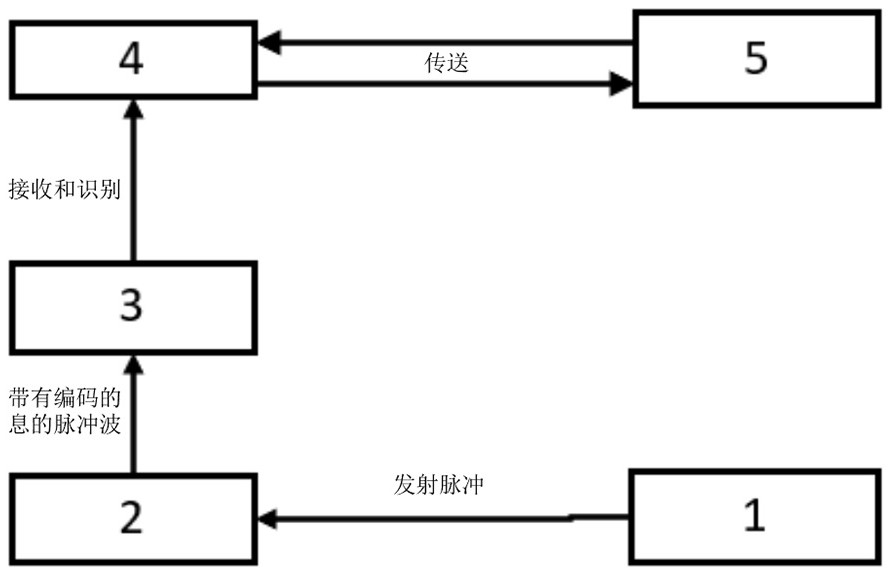

[0056] For the first form, the hardware part of the monitoring system of the lightning protection wire 3 mainly includes the blades arranged on the wind turbine tower, the lightning protection wire 3 arranged inside the blades, the lightning protection wire 3 is glued to the inner wall of the blade, and the lightning protection wire 3 is automatically connected to the inner wall of the blade. The blade tip of the blade is arranged to the blade root of the blade; the passive sensor system 2 is arranged at the blade tip of the blade, and the passive sensor system 2 and the lightning protection wire 3 are non-contact connections; The edge terminal equipment 4 is arranged on the lower lead of the lightning conductor 3; the radio frequency signal transmitting device 1 is arranged on the tower of the wind power generating set directly opposite to the tip of the blade.

[0057] The radio frequency signal transmitting device 1 mentioned above includes a power supply, a radio frequency ...

Embodiment 2

[0063] For the second form, such as Image 6 As shown, the hardware part of the lightning wire monitoring system is set on the blades on the fan tower and the lightning protection wire 3 arranged inside the blades. The lightning protection wire 3 and the lower lead wire are connected by fittings. The stranded wire is laid inside the blade and glued to the inner wall of the blade. The passive emission system is arranged at the position of the tip of the blade, and is non-contact connected with the lightning protection line 3. The lightning protection line 3 is arranged from the tip of the blade to the At the blade root of the blade; the tower radio frequency signal receiving device 6 is arranged on the tower so that when the blade tip is perpendicular to the ground, the passive sensing system 2 corresponds to the tower radio frequency signal receiving device 6; as figure 2 As shown, the power transmitting terminal equipment 7 is installed on the lower lead of the lightning con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com