Drying production line of chlorinated polyethylene

A chlorinated polyethylene, production line technology, applied in the direction of drying room/container, dry solid material, dry cargo handling, etc., can solve the problems of easy sticking to the wall and easy mixing of dry and wet materials, so as to facilitate maintenance and cleaning, and improve uniformity Sex, the effect of preventing adhesion phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

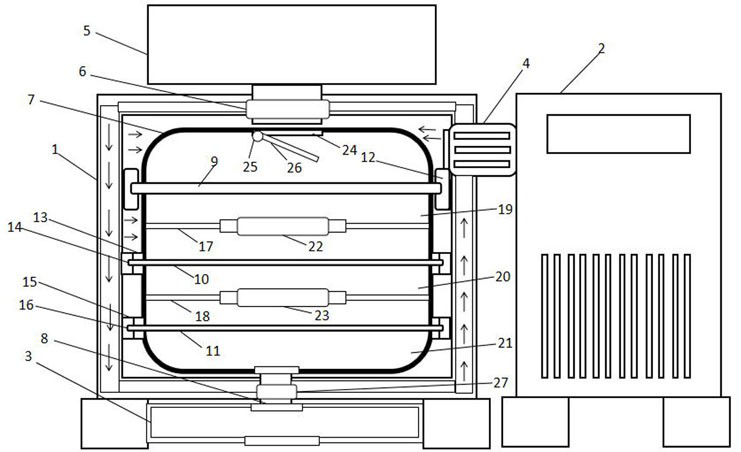

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0021] combine figure 1 It can be seen that a drying production line for chlorinated polyethylene includes a hot air circulation oven 1 in a vertical standing structure, a hot air supply box 2, and a vacuum transfer box 3 connected with a vacuum pump. The vacuum transfer box 3 The function is to transfer the dried chlorinated polyethylene material to the next process.

[0022] In the above structure, the hot air supply box 2 is connected with the hot air circulation oven 1 through the fan 4; the upper end of the hot air circulation oven 1 is provided with a material placement box 5, and the bottom of the material placement box 5 is provided with a material placement box 5 The first electro-pneumatic valve 6 for lowering the materials inside, and the vacuum transfer box 3 are located at the bottom of the hot air circulation oven 1 .

[0023] A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com