An analytical method for thermal buckling critical temperature of aircraft panels

An aircraft panel and critical temperature technology, applied in the field of aircraft manufacturing, can solve the problems of increasing complexity of thermal buckling behavior, destroying structural stability, complex thermal physical properties and mechanical properties, etc., and achieves the effect of simplifying the model and simple processing method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

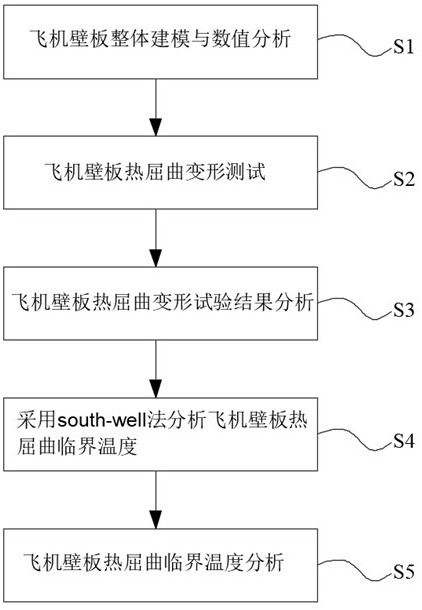

[0052] This embodiment is a method for analyzing the thermal buckling critical temperature of an aircraft panel, such as figure 1 shown, including the following steps:

[0053] S1. Overall modeling and numerical analysis of aircraft wall panels, including the following steps:

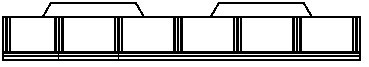

[0054] S1-1. Select the mixed-structure aircraft wall panel including composite material laminate and aluminum alloy plate reinforcing rib as the test piece, and establish the geometric model of the test piece, such as figure 2 As shown, the composite material laminate is 2520mm long, 300mm wide, and 3mm thick, which is used to simulate the skin of the aircraft panel. The laminate plate and the aluminum alloy plate reinforcing rib are connected by rivets.

[0055] S1-2. In the calculation process, the material properties of composite material laminates and aluminum alloy plate reinforcing ribs are assigned. The material properties of composite material laminates include: elastic modulus, Poisson's ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com